|

[신제품] 600012 Cobra 811 B-e 2.0 1/8 4wd buggy EP - 1/8 전동버기

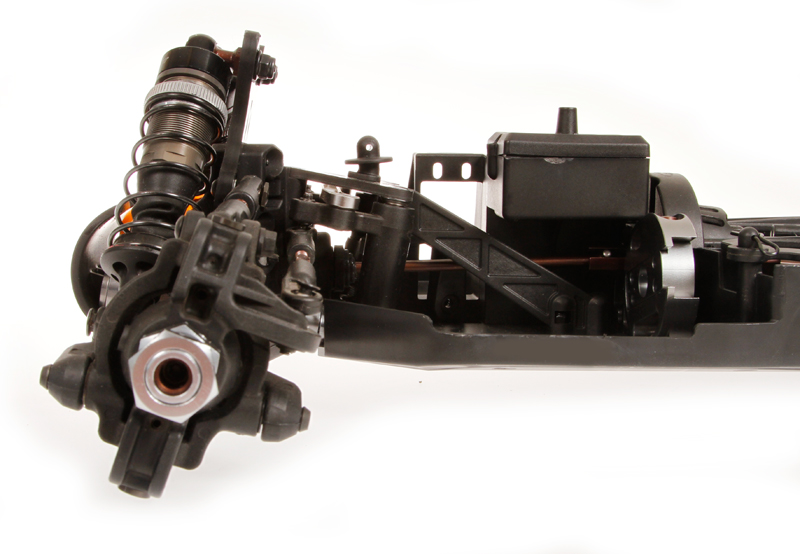

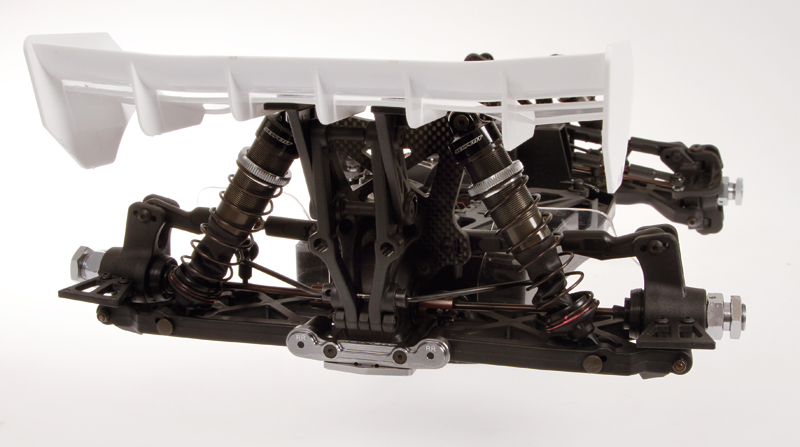

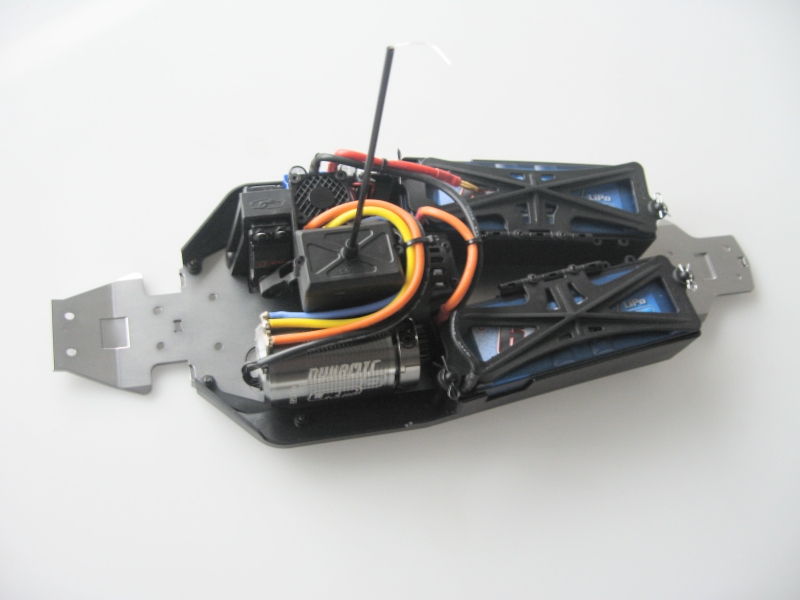

Serpent 1/8 scale buggy in electric powered version. Serpent Cobra Buggy E. The Cobra 811e is based on the same platform as the gaspowered buggy. State of the art design of the central section, with advanced integrated standing servo, receiver, speedo bracket, ingenious motor-bracket and lay-down Lipo-pack configuration with practical lid-system. Extremely narrow and low design, optimised for overall weight balance. New low body-design and lower rear wing / wingmount. Key new features - new rear end geometry with longer lower arms - more shocktravel - larger bearings in the transmission and wheelaxles Available mid april 2013.

Specifications

| name: |

Serpent Cobra-Be / 811-Be |

| class: |

1/8 scale 4wd offorad, electric powered |

| type: |

kit-version, high end competition |

| : |

|

| differential: |

front, center and rear |

| shocks: |

16mm bigbore |

| included: |

kit, body, wing, full color manual, decals, set-up sheet |

| not included: |

tyres, wheels, radio equipment, elecronics |

Description

Introduction

Serpent Cobra 811 Buggy Be 2.0 1/8 4wd

Main new features

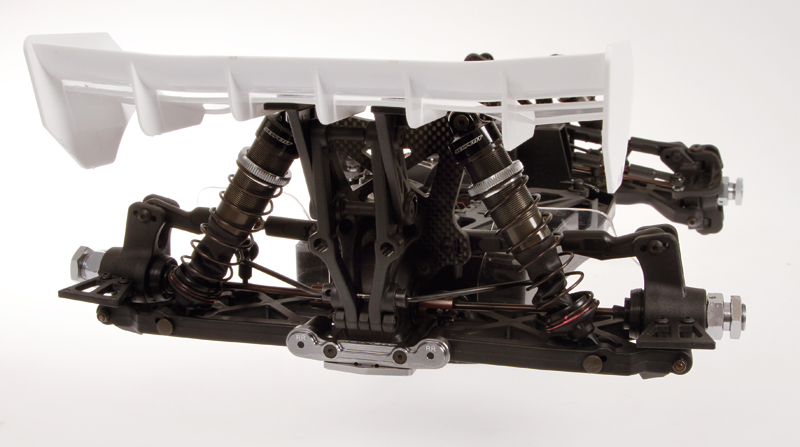

- new wider rear end with new geometry for more rear traction and an easier handling car with wider sweetspot

- rear shockabsorbers moved to the back of the shocktower

- longer rear shocks; with longer housing and shockrods for more travel

- rear wing with integrated holders for the ballraced rear anti-roll bar

- longer rear lower arms, new higher carbon shocktower, longer rear shock, new upright

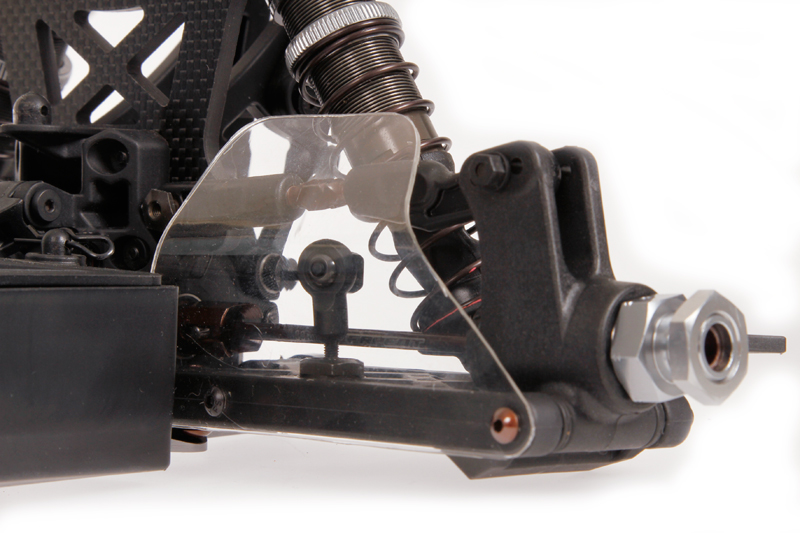

- lexan mud-guards to mount on lower rear arms

- nylon mud-scrapers mount on the rear uprights

- improved differential gears - as already in the Be version

- larger bearings in steeringblocks and uprights 8X16X5 (2) and 15x21x4 (2),

- transmission using larger bearings 8x19x6 and 13x19x4 and new couplers for extra durability –

The kit includes car, clear body with mask, 4 racing wheels, rear wing, decal and full color manual. The full package to compete in high end racing, finish finals and win ! Shipping middle of march 2013.

This new development for Cobra buggy is realized after another full year of racing across the globe, listening to feedback from many (team)-drivers and dedicated testing on many different surfaces. The feedback from the drivers on the Cobra Buggy in general is very good, the durability is rated as best in the market, the shocks are toprated, and the diffs and drivetrain with new gears and larger bearings can now withstand any rigors and will last and last ! According to same drivers a more responsive rear end, combined with a bit more steering would bring the Cobra on the highest level.

Well, the changes as below accomplish just that, and for sure we will continue the superb quality on the kit overall !

Key changes for the 2.0 version

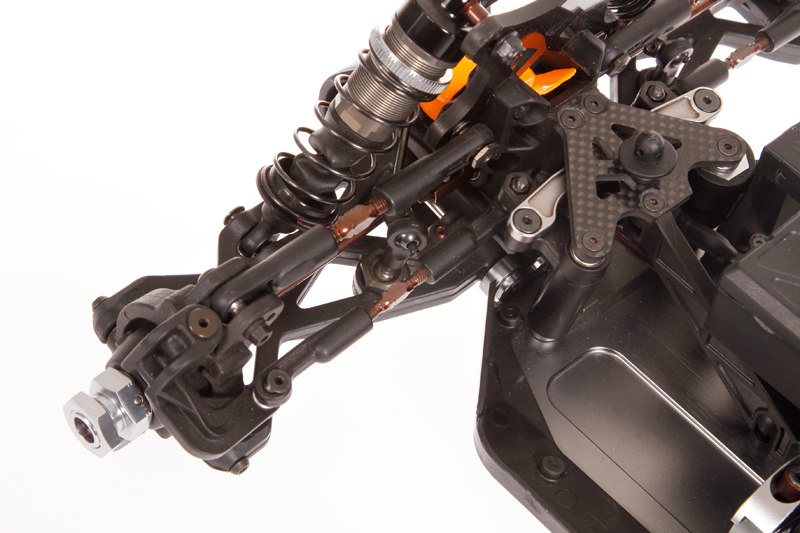

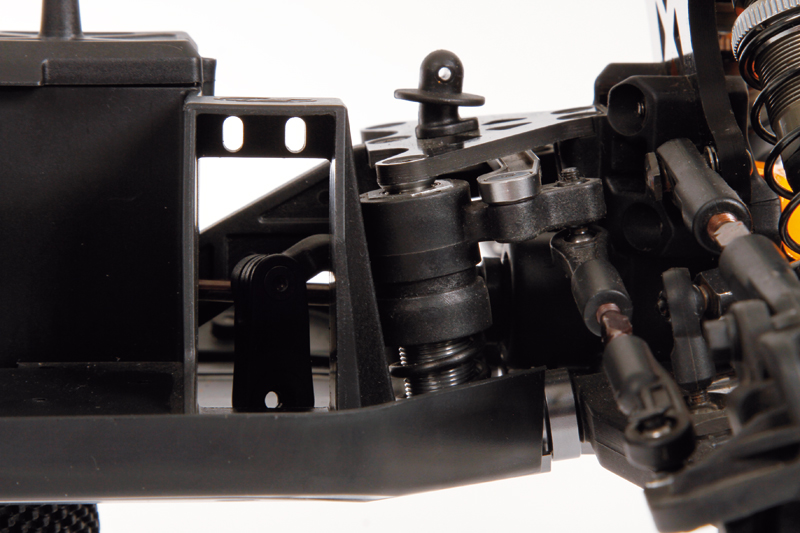

- Improved rear geometry with wider rear lower arms, new uprights and new shock position

- Longer rear shocks and higher rear carbon shocktower for more travel

- Shocks moved to the back, to make access and adjusting easier, and make rear end more stabile and responsive

- rear wing with integrated holders for the ballraced rear anti-roll bar

- lexan mud-guards to mount on lower rear arms

- nylon mud-scrapers mount on the rear uprights

- improved differential gears - as already in the Be version

- larger bearings in steeringblocks and uprights 8X16X5 (2) and 15x21x4 (2),

- transmission using larger bearings 8x19x6 and 13x19x4 and new couplers for extra durability –

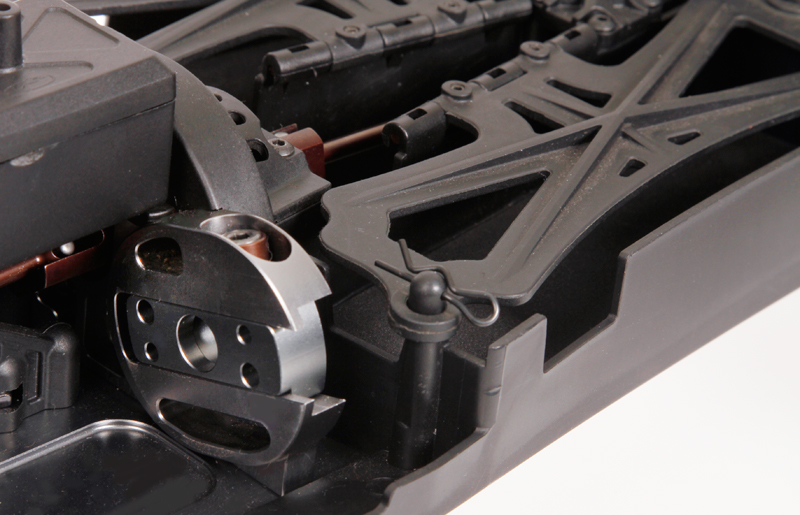

Chassisplate

Chassisplate in 3mm 7075 T6 aluminium , with machined pockets to create flex make lighter. Kick-up angle on front for stabile landings. Countersunk holes. Slots to locate the front and rear suspension mounts precisely. Angled sides to increase stiffness. Laser engraved Cobra logo.

Bumper

Aligned with chassis kikc-up for precise landings and to protect front suspension holde rand anti-roll bar.

Chassis stiffners

Composite stiffner front and rear, to give extra stiffness, but still allow some flex as needed.

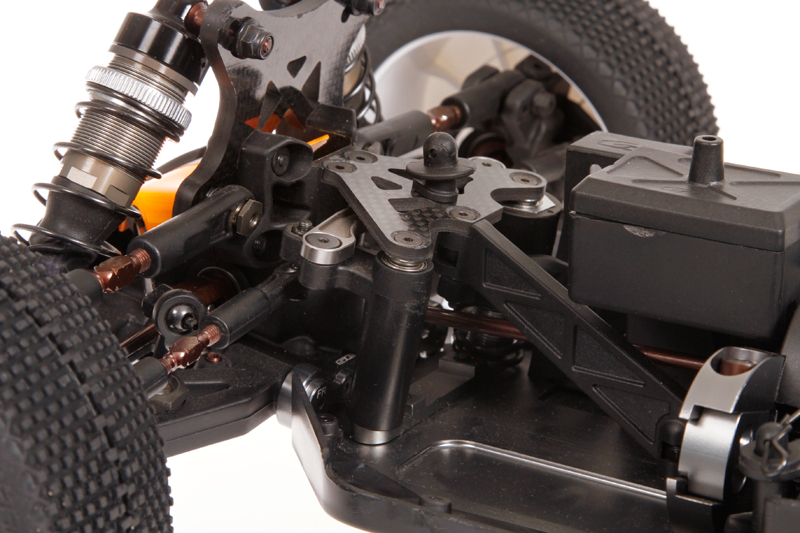

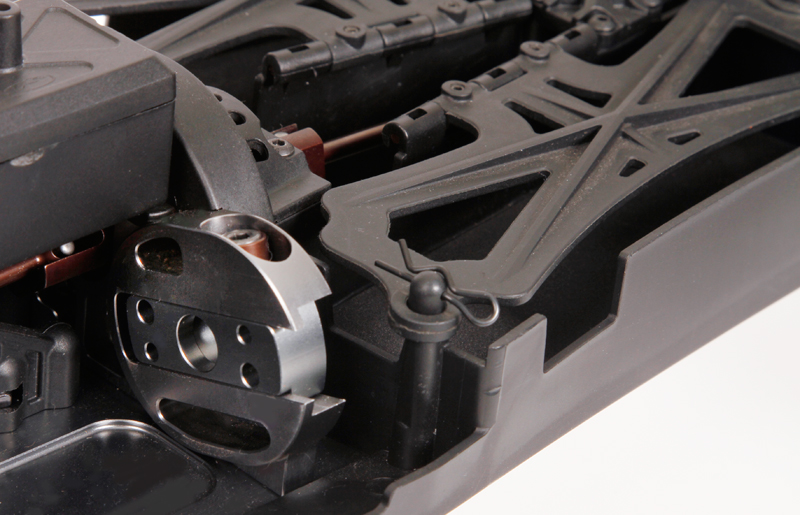

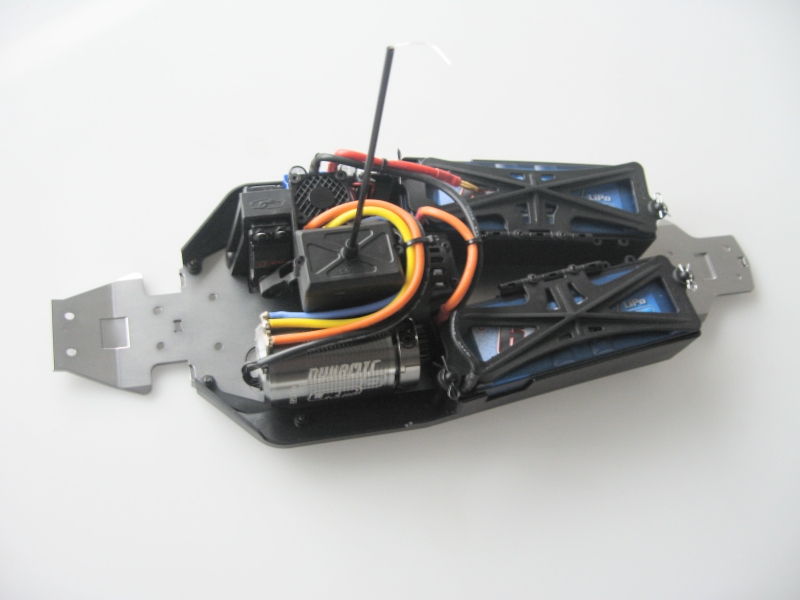

Central radio / servo mount

Composite compact radiobox which offers good space for the steering servo and the receiver . The whole assembly including linkages can be taken off easily and fast in one go, when cleaning the car, or doing maintenance.

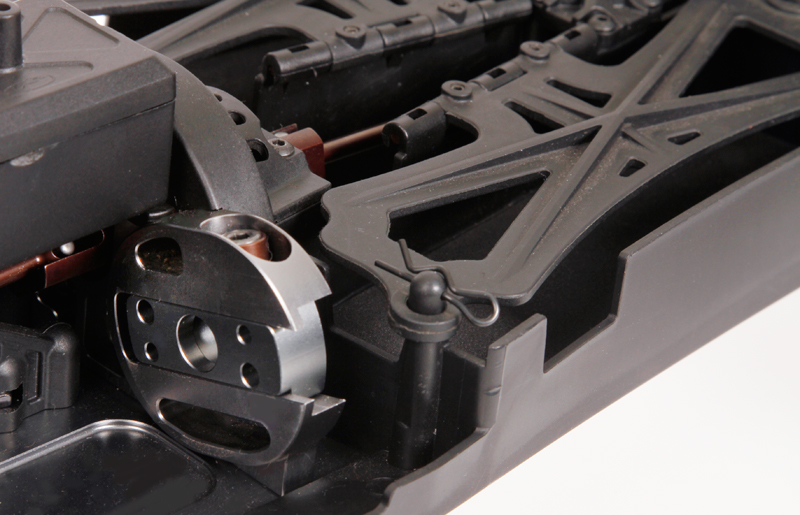

Battery-cases / side-guards

The main eyecatchers are the extremely low laydown longtudinal placed battery-packs at each side of the car, being part of the side-guards, securely fastened with a flip-lid, for easy and fast battery changes. The weight low in the car and in the right position, well balanced. The Lipo holders comply with ROAR legal packs / dimensions.

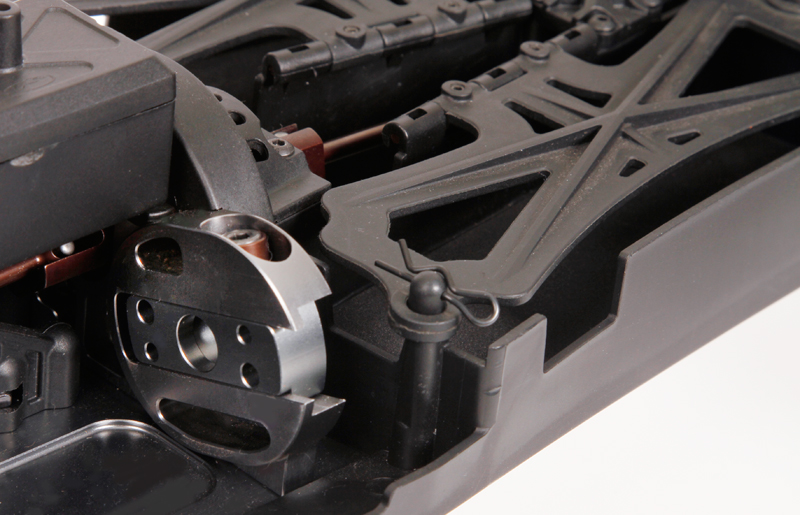

Motormount:

The motor is placed in the most optimal position in the car, keeping motor-forces and transmission parts / alignment in mind. Only one-screw is needed to secure the BL motor, in the nicely designed durable machined aluminium motormount. Space for additional motor-cooling available as needed.

The space for the motor allows a maximum motor-length of 70mm, which covers most widely used motors ( except for the truggy / monstertruck motors).

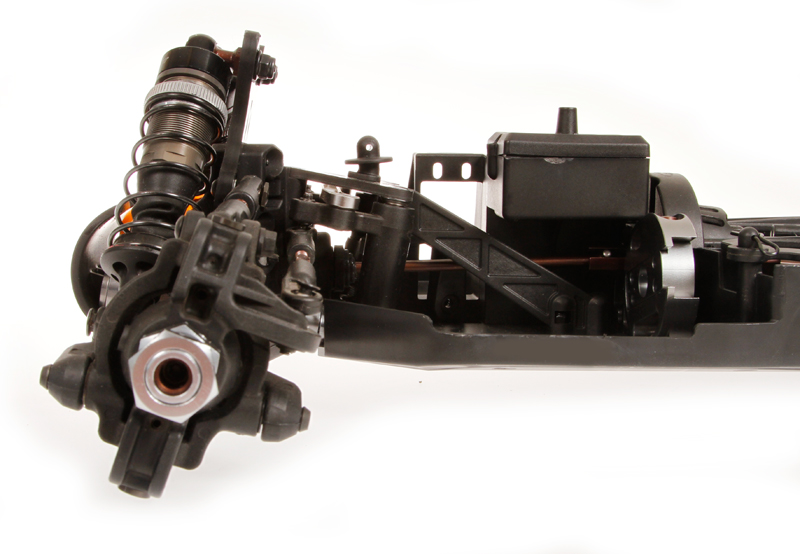

Suspension brackets

Beautifully machined 7075 T6 suspension brackets in anodized, laser angraved. Precision fit for the nylon roll center inserts and pivot balls / pins.

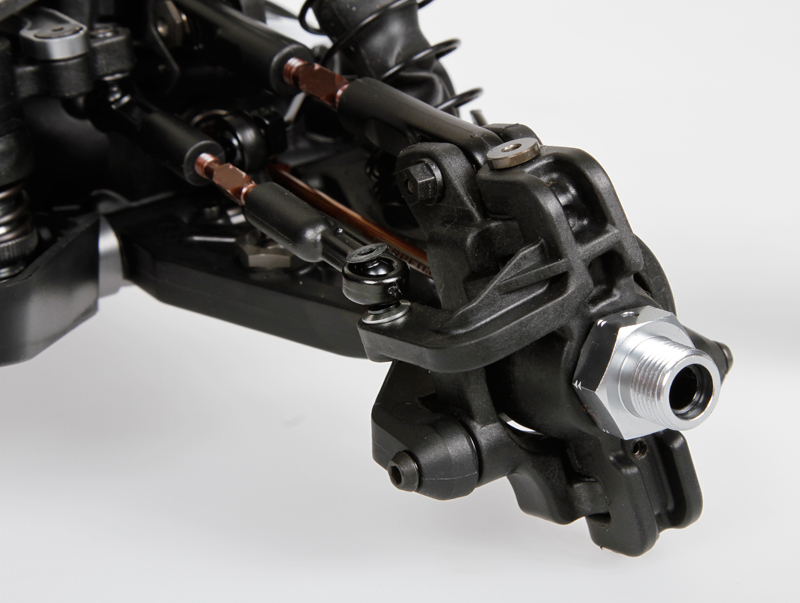

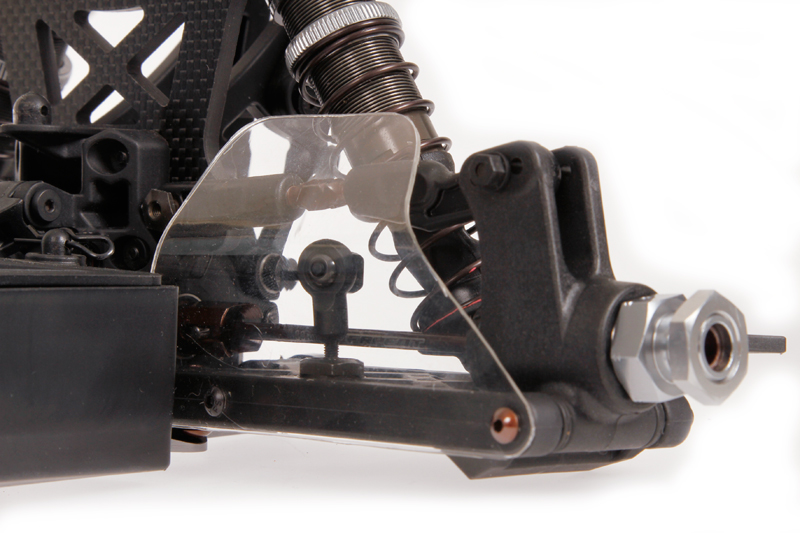

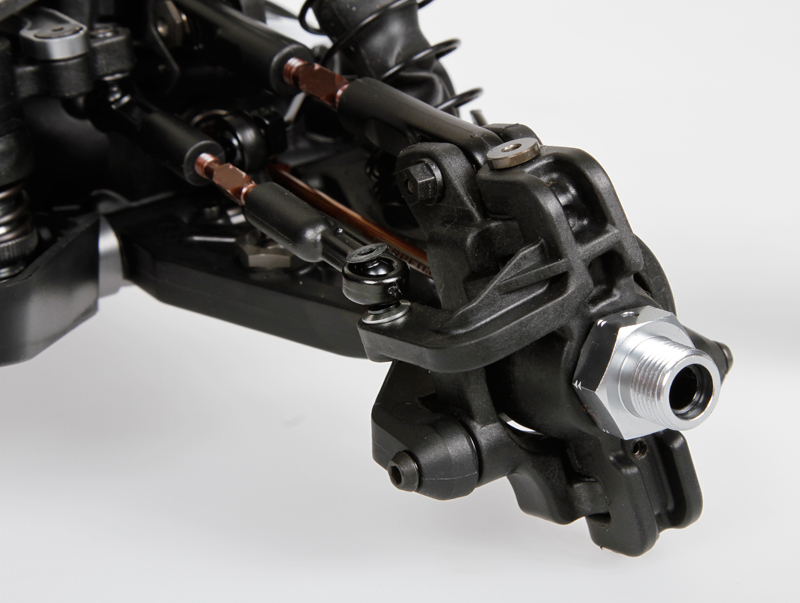

Steeringblocks assembly

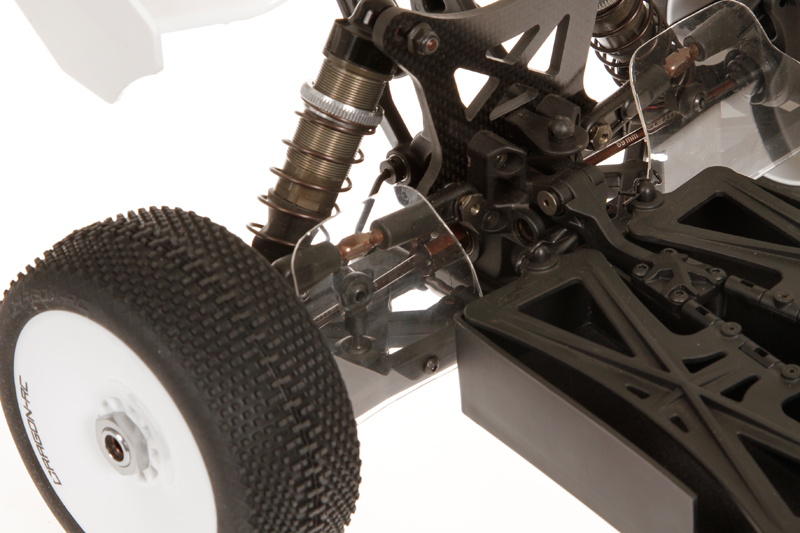

Composite steeringblocks combined with 10 dgr C-hubs for precise steering. Spring steel wheel-axles with large size bearings and larger inner with precision threaded aluminum wheel-hubs with offset . Flanged and serrated wheel nuts to guarantee that you will not loose a wheel nut in a race.

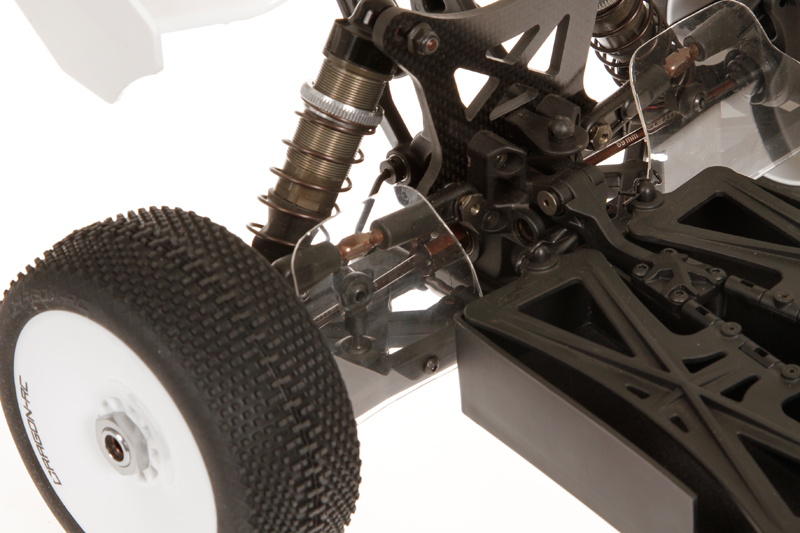

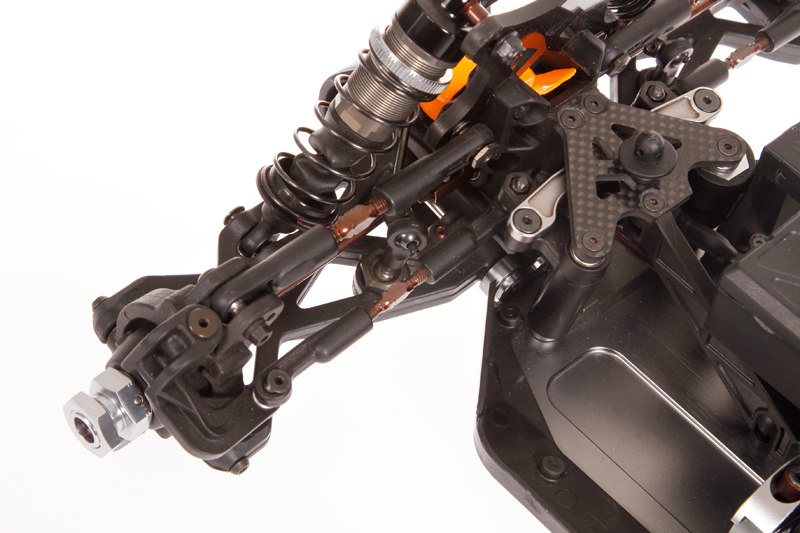

Front suspension

Durable oversized lower suspension arms in strong composite nylon. On the lower side the special shaped downstops screws are mounted. The lower shock-mounting pins are secured with a small grubscrew from the bottom.

Front anti-roll bar

The ballraced front anti-roll bar system, consist of a spring steel bend wire, which is guided through the diff-cases and runs in ballraced steel adaptors. The wire is linked to the lower suspension arm, with a captured adjustable threaded pivotball, for very precise and low friction operation and easy tuning.

Shocktower and bodymounts front

4.5mm thick carbon shocktower with 5 upper positioning holes for the shocks and and 6 holes for roll-center positions. 1 centrally located adjustable bodymount , and 2 forward mounted adjustable bodymounts, all with flip-tops.

Angled steering system / servo saver

The bell cranks are angled to reduce the angle of difference between the total caster and steering plane. Therefore you will have less bump steer and a truer steering Ackerman through the entire range of suspension

Ackermann plates

With the design of the steering bell cranks when changing the Ackermann you will not need to adjust your steering tie rods. You simply will only need to adjust your end points on your radio..

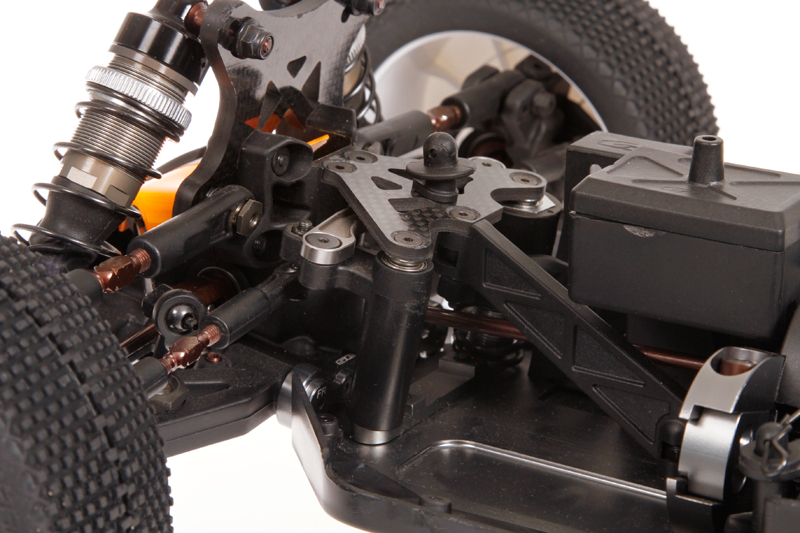

Rear suspension arms

Durable longer oversized lower suspension arms in strong composite nylon. On the lower side the special downstops screws are mounted. The lower shock-mounting pins are secured with a small grubscrew from the bottom.

Mud-guards

Superlight polycarbonate mud guards mount to the new lower suspension arms, and will keep dirt away from your anti-roll bars transmission and wheels.

Rear uprights assembly

Composite uprights with 3 upper roll-center positions. Strong steel track-rods with L/R threading and strong balljoints to pre-set camber. Spring steel wheel-axles with large size bearings and larger inner ones with precision threaded aluminum wheel-hubs with offset . Rubber dustcovers in the rear to protect the cvd system and keep the lubrication inside. Flanged and serrated wheel nuts to guarantee that you will not loose a wheel nut in a race.

Mud scrapers

Composite mud scrapers which mount to the new uprights, and will keep the inside of your wheel cleaner in case of muddy conditons. Kept on the bigger size, so may need to grind to fit your brand of wheels.

Rear anti-roll bar

The ballraced front anti-roll bar system, consist of a spring steel bend wire, which is guided through the rear wingmount and runs in ballraced steel adaptors. The wire is linked to the lower suspension arm, with a captured adjustable threaded pivotball, for very precise and low friction operation.

Shocktower rear

4.5mm thick carbon shocktower, integrated into the rear section for extra stiffness, with 5 upper positioning holes for the shocks and 6 holes for roll-center positions.

Wingmount and bodymounts rear

Composite rear wing, with strong nylon adjustable rear bodymounts on wide body-support bridge located far enough to the rear, to support the bodies in best way.

Captured pivot pins and balls and bolted hinge pins

All spring-steel hinge pins are either captured or bolted in place and made in spring-steel quality. This insures your chances to finish an hour long main event, while battling for the lead. This relieves stress on the hinge pin when adjusting the kick up, or anti squat. Your pin is free to rotate to any angle without binding.

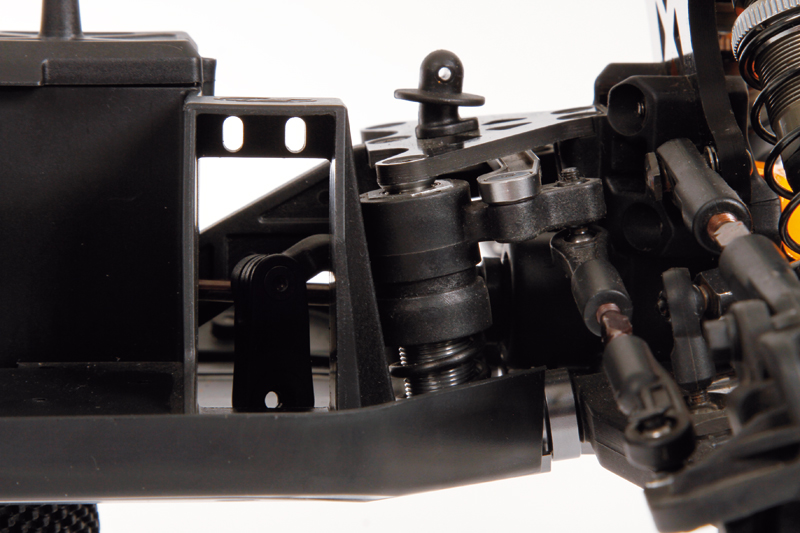

Shockabsorbers RCM big-bore 16mm

Hard Teflon coated threaded shockbodies with 4mm shock-rods. Hard anodized aluminium screw on shock-tops with Serpent laser engraving. Pre-load adjusters with o-rings inside. Shocks use large diameter membrames and large diameter o-rings and bushings to create a supersmooth and leak-proof package. Large diameter pistons are held in place by a nut on the polished shock-rods tops. Open type spring retainer to let dirt out easy. The shock-shafts are protected by rubber boots.

RCM shock springs

Colorcoded progressive shock springs are supplied for the 1st standard set-up and all springs are grinded flat top and bottom, and checked individually for tension and length and matched.

Compact geardifferentials

Very compact gear differentials with very smooth metal sintered gears, and steel shaft. Perfect sealing case with special gasket and o-rings. Very light and durable outdrive cups in spring-steel. Hardened spring-steel diff-coupler 13T with connector running in 2 oversized bearings The Cobra-E uses a 13T / 44T combo gearing. 46T central diff gear. This drive ratio will provide amazing acceleration combined with the low vehicle weight.

Front and rear cvd-sets

Both front and rear captured driveshafts are being used with CVD system. Durable yet light spring steel engraved driveshafts with hard steel pins.

Spring steel transmission parts

The front and rear thin but strong spring steel cardan shafts connect the differentials .

Body

Serpent superlow Cobra E buggy body with film and masking tape is included in the kit.

Rear wing:

Low version strong rear white aero rear wing is included for great downforce and straight line stability.

Oils and grease

The shock-oil, diff oil and some grease is supplied to meet the standard set-up.

Manual and set-up

Full color manual with easy to follow assembly steps, exploded views for easy spares ordering, a blank and standard set-up sheet for a good start set-up.

Decals

Black and white promo body-decals ; Serpent generic and Cobra ones.

Packing

Parts are packed according to the steps explained in the manual.

Service and Support

The Serpent distributor, dealer or agent is your source for more info, but also the Serpent website and the member section and the Youtube channel provides lots of information.

|