- Brand:

- Serpent

Product Type:- Electric cars > 1/8 onroad

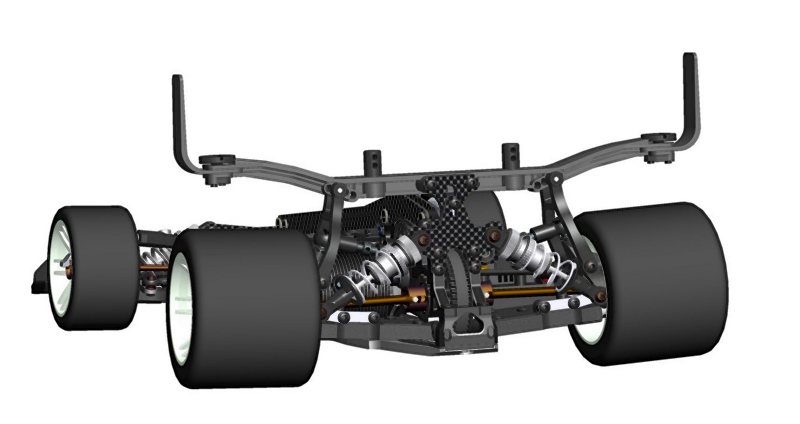

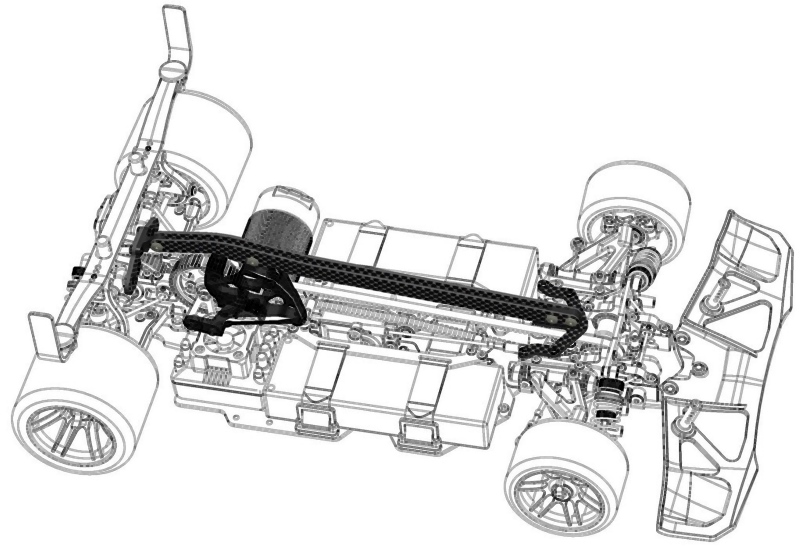

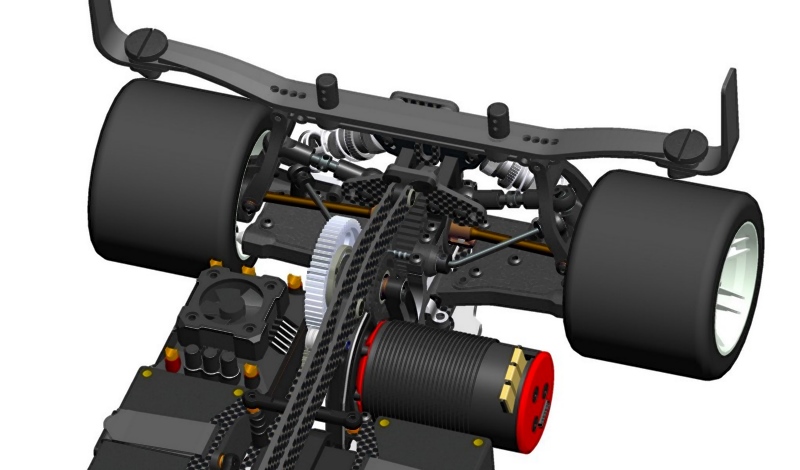

The Serpent Viper 988E is the electric version of the 988 gas car. It brings together all our experience in Nitro 1/8th and 1/10th Electric Touring cars. The Viper988E features the race proven geometry, bulletproof driveline and super smooth shock absorbers of the 988 Nitro car, with the weight distribution, flex options and belt drive layout of the 4X touring car.

> Downloads

| 29-05-19 | Manual Viper 988e | 32 MB | Download |

| 21-05-19 | Serpent tools | 1 MB | Download |

| 21-05-19 | Ref guide Viper 988e | 21 KB | Download |

> Description

Bringing together the best of both worlds has created the ultimate 1/8 electric racing car. We managed to reduce weight, improve weight distribution and efficiency. The design of the 988E also makes it super easy to work on for quick setup adjustments and maintenance.

Key NEW features

2 belt layout with perfect weight distribution and improved transmission efficiency.

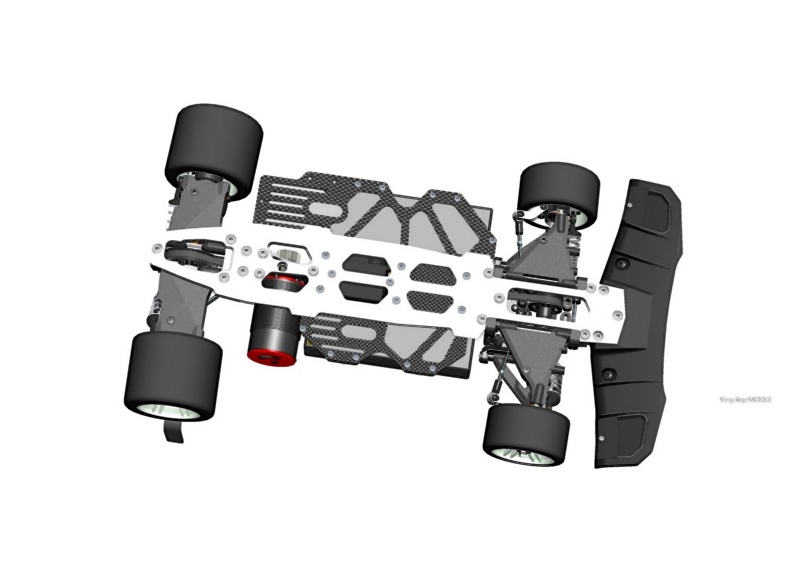

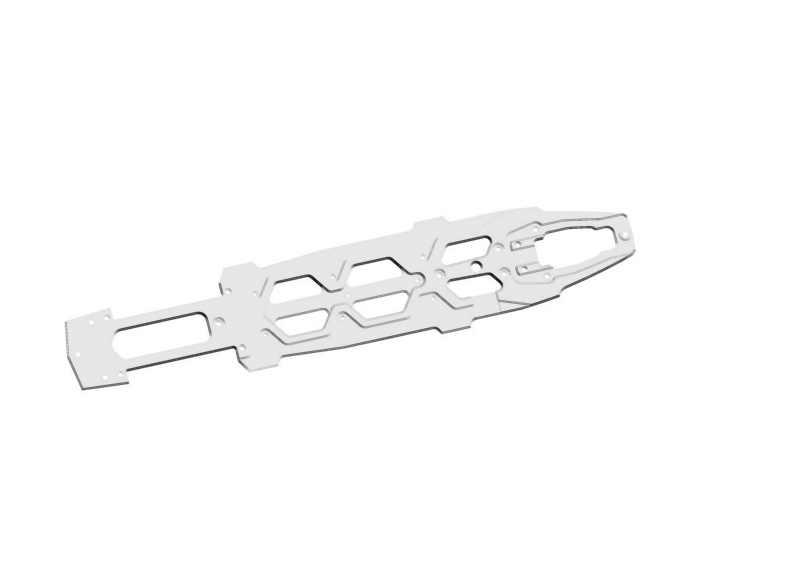

very light, ultra-narrow 4mm chassis-plate with symmetric layout and central fixing points for suspension, batteries and electronics

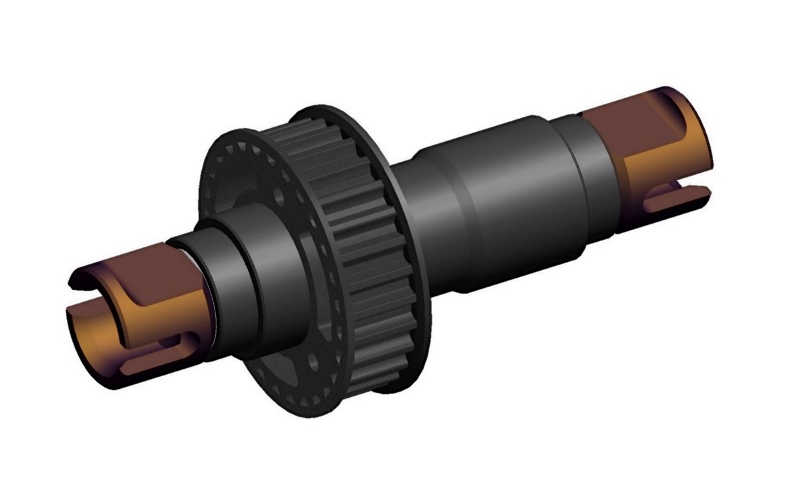

Ultra-true, low-friction mid shaft assembly, featuring 2 big-size ball bearings. The assembly is easy to remove for spur gear changes and general maintenance

Carbon, vertical twin top deck design, creating the backbone of the car. It gives the chassis the perfect balance between torsional flex and longitudinal stiffness.

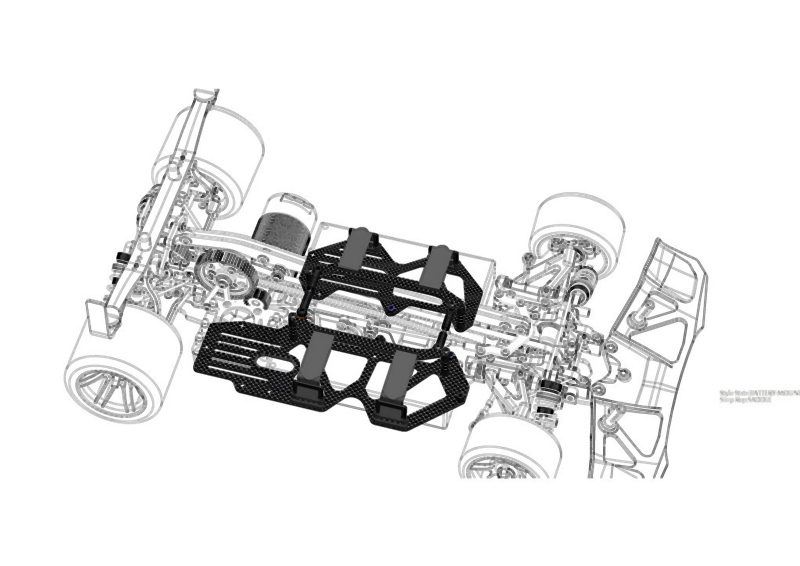

Multiple layout options to allow for 4-S layout.

And also 6-S layout.

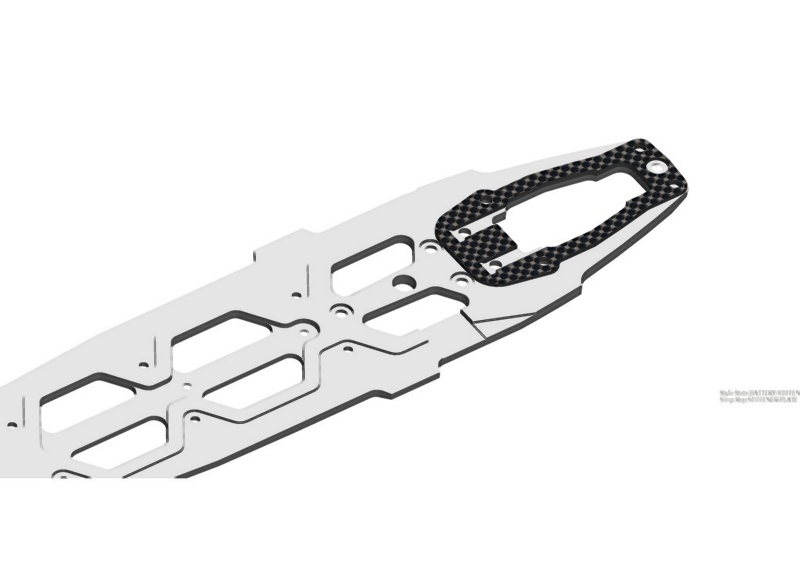

Symmetrically mounted Carbon battery mounting plates with Velcro strap system and integrated, flex-free stiffeners

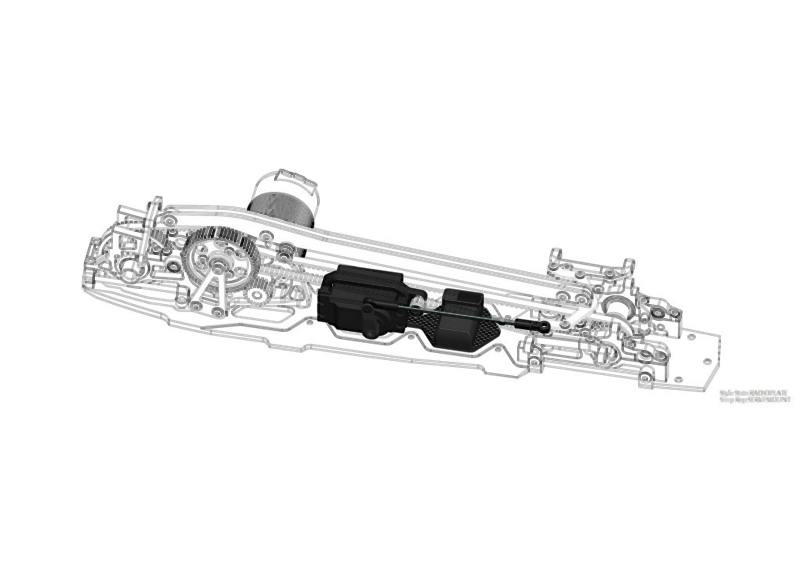

Low, centrally mounted radioplate

General features

7075 T6 Aluminium 4mm chassis plate

The 4mm aluminium chassis has perfect symmetrical shape for even flex and weight distribution. The ultra-narrow chassis is very light, while it still remains stiff in combination with the carbon vertical top deck backbone. The Viper 988E logo is laser engraved.

A carbon spacer for the rear end stiffens the chassis and acts as a location device for the bulkheads and brackets of the rear suspension.

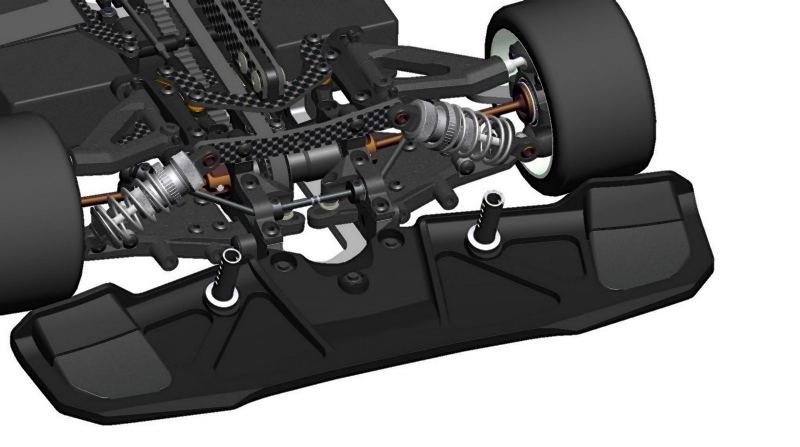

The newly developed front Flow bumper is a very durable and offers removable inserts. It’s very easy and quick to change the aerodynamic characteristic in a matter of seconds. By just removing or adding the inserts to increase or decrease steering and turn-in. The ribs in the bottom guide the air below the chassis and body.

The strong aluminium front body posts are eccentric, to allow movement of the body a few mm forward and backwards to optimize steering and downforce.

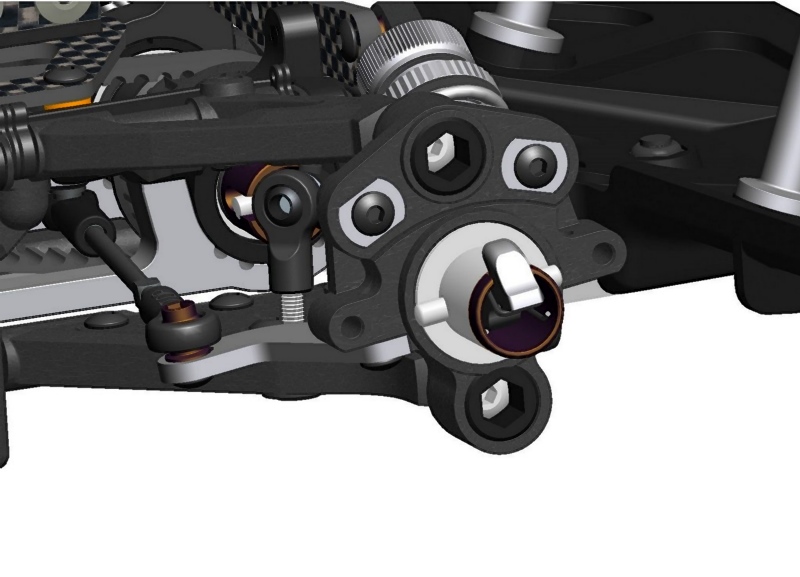

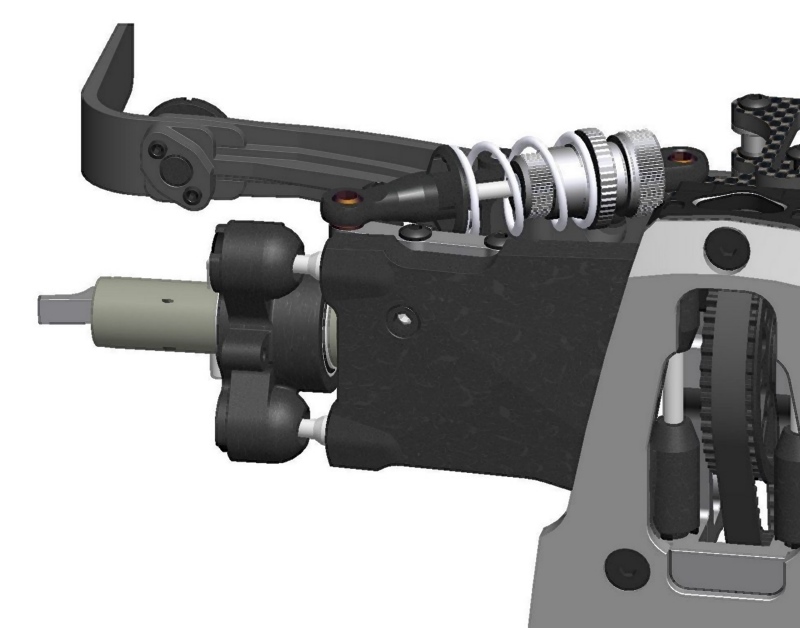

The steering blocks, which are equal left and right, offer a system to change the axle position to a “trailing” or “leading” position, and the ability to change the kingpin-inclination and offset. This allows multiple options to fine tune steering balance in all phases of the corner. The steering block features an aluminium plate to connect the spring steel track-rods. They have 2 Ackermann options.

Optional carbon fibre disks can be mounted on the side of the steering blocks and uprights for aerodynamic adjustments.

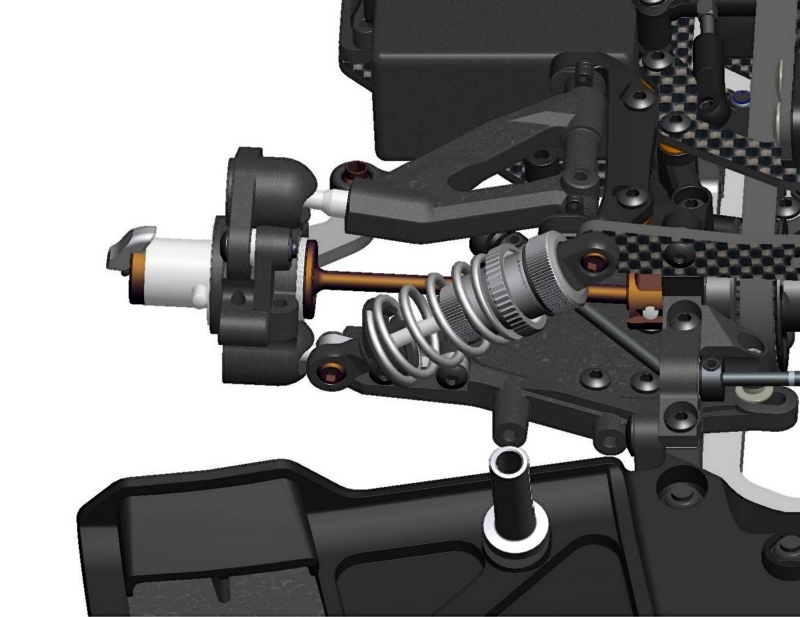

The long durable front lower wishbones are in a new hollow type design with closed bottom for improved aerodynamics and have separate top mounted moulded inserts. An aluminium shock mount plate is screwed onto the lower wishbone. This allows the shock attachment point to be placed further outwards improving shock motion. The front lower arms are mounted to the front brackets with nylon holders. The kit includes 2 versions: in and out. This system also enables quick and easy front drive shaft maintenance.

The left and right interchangeable upper arms are mounted with 3 position nylon suspension pin inserts. The 3 position inserts allow camber-change adjustments and are held in place by the anodized aluminium top brackets. Below the top brackets, spacers can be used to change their angle or height. Caster is adjusted with clips on the upper pivot pins. The same clips are also used on the lower pivot pins to change wheelbase.

The wire type front anti-roll bar is ball raced. It is easy to change and adjust due to the open front end design. The standard wire is 2.5mm and 2 optional thicknesses are available. The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The steering blocks are connected to the arms with spring steel 8.5mm pivot balls, which run very smooth and well protected in nylon cups, and are easy to adjust with a 2.5 hex tool.

The black anodized aluminium front axle has Japan made one-way bearings. Spring steel drive cups connect to the long and thin spring-steel drive shafts with CVD system. The ball raced spring steel wheel axles have aluminium quick-change levers. The open front end design allows for very fast and easy removal of the front axle and driveline parts.

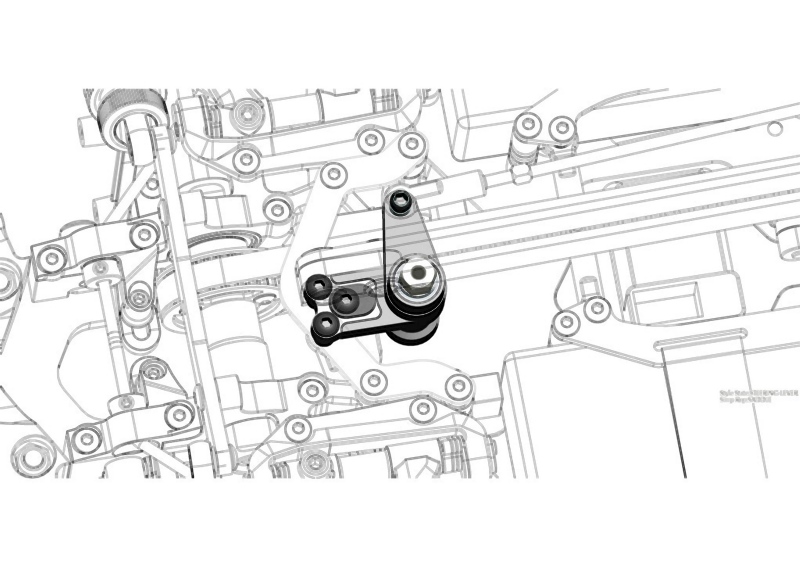

The central mounted steering lever allows easy and fast Ackermann adjustment. The steering lever features a top mounted insert which can be used in 3 positions. Another 2 Ackermann positions are available on the steering blocks.

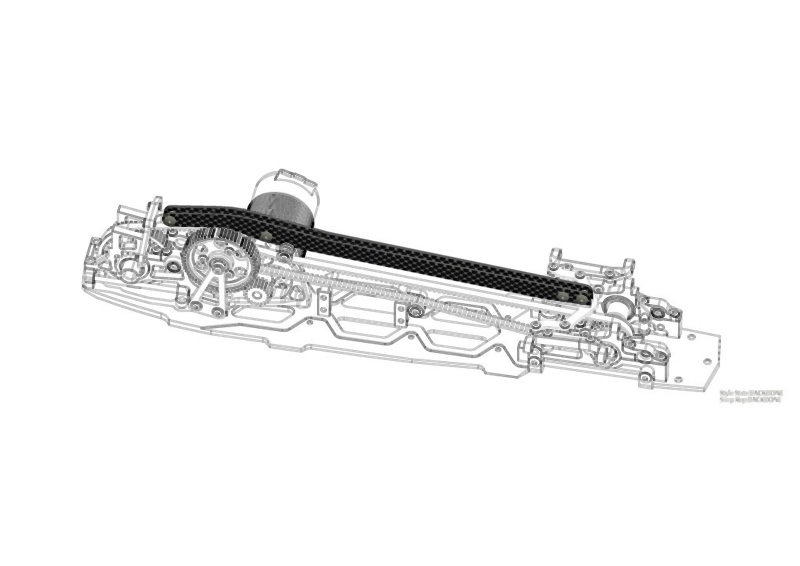

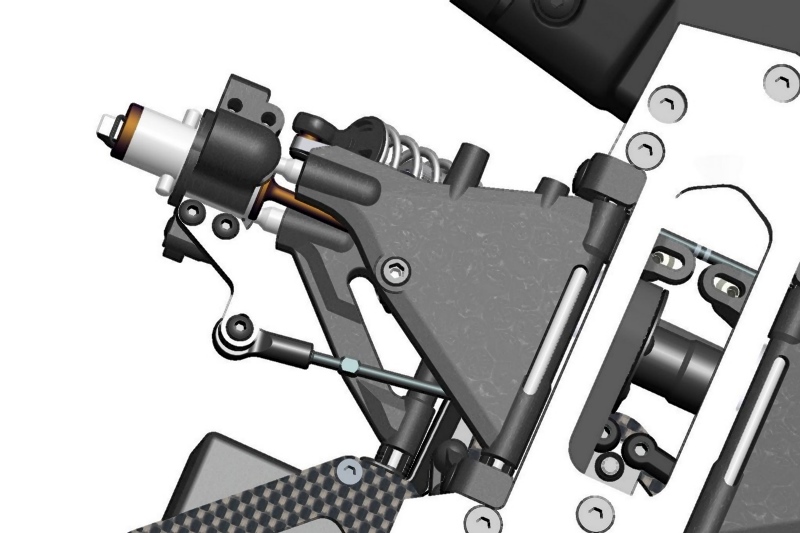

The vertically placed top decks stiffen the chassis in the longitudinal direction, while controlling the torsional flex. They are constructed of 2 high grade carbon plates that connect the central motor mount to the front and rear ends of the car. Their design was taken from our race proven 4X electric touring car and changed to the demands of the Viper 988E platform.

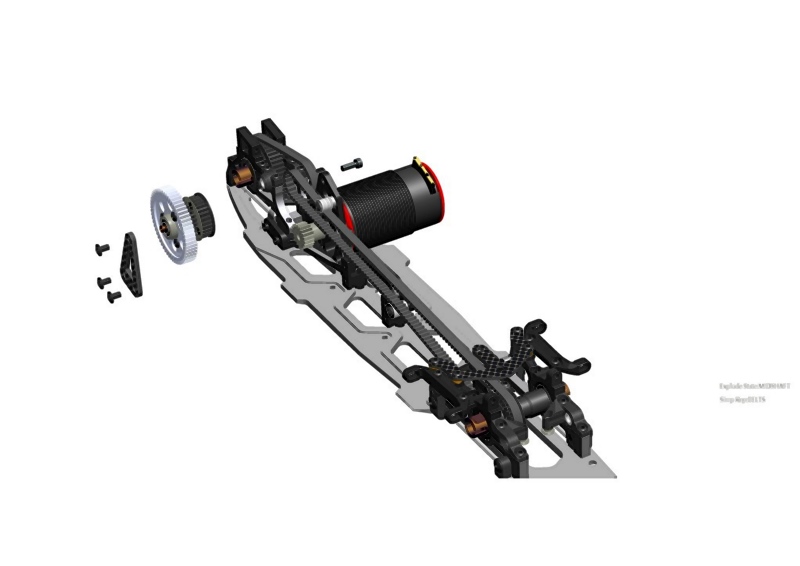

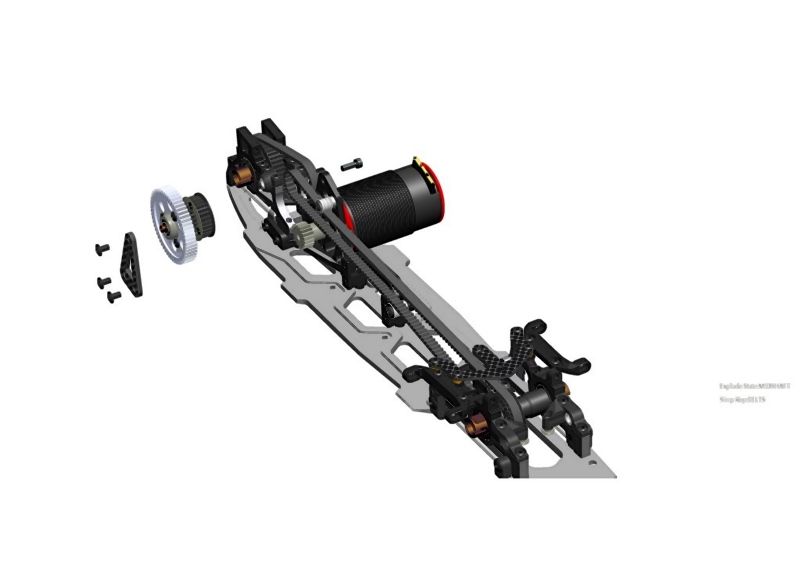

The Viper 988E has been designed for maximum driveline efficiency. The design is taken from the 1/10th electric where efficiency is very important and adapted to the power of the 1/8th application.

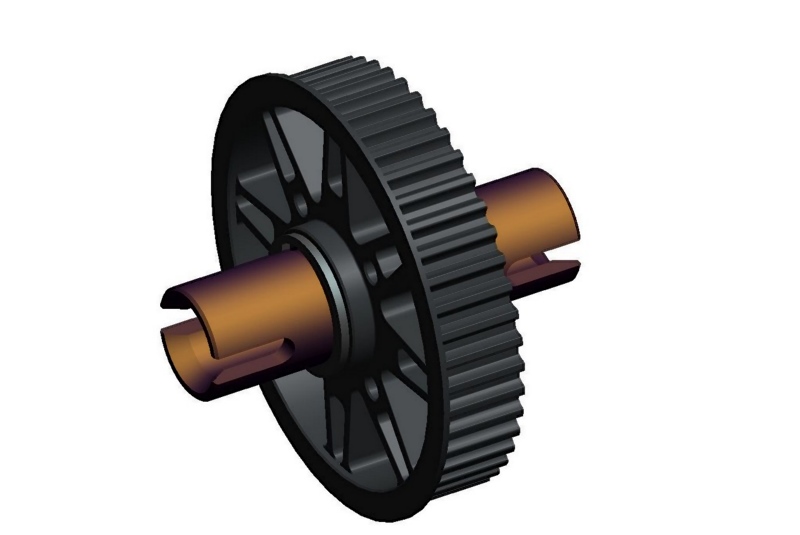

The mid shaft assembly features 3 bid-size ball bearings in total to achieve a low friction, super-true rotating construction. It is very easy to disassemble the mid shaft to change the spur gear or belts.

The final drive ratio of the car is 1.71

28T front pulley

19T mid-front pulley

28T mid-rear pulley

48T rear axle pulley.

All the super round and true pulleys have holes in the side flanges to allow dirt and dust to move out easier. The 988E has larger diameter pulleys with more teeth which makes the belts run smoother and with less friction.

The belts are low friction type as standard. The belts are optimised for durability and low friction and are 6mm wide

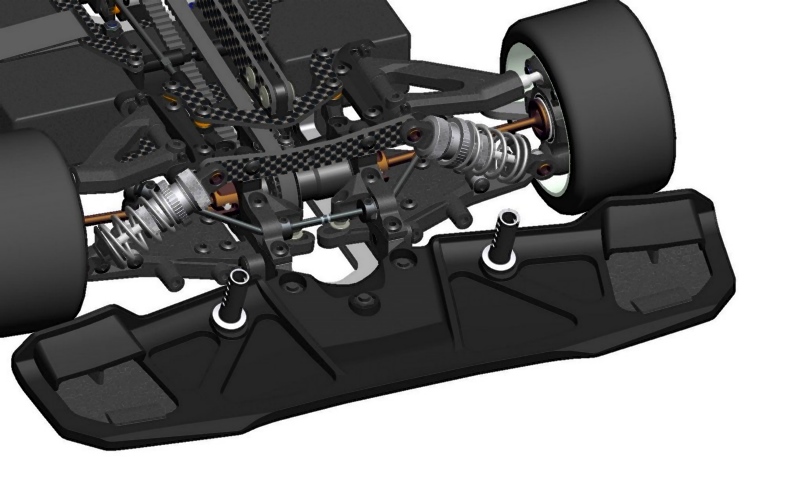

The rear end construction with aluminium brackets is a very open design, which allows for easy of maintenance and cleaning. Dis-assembly requires the removal of only a few screws. Replacing a belt if needed, is a simple task. The eccentric bearing holders on the rear shaft allow adjustment of belt tension. The whole rear end can be removed as one unit from the chassis by removal of only a few screws.

The wire type rear anti-roll bar is ball raced. It is mounted in the rear bearing blocks and is easy to change and adjust. The standard wire is 2.5mm and 2 optional thicknesses are available. The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The narrow solid rear axle in Serpent spring steel has a lightweight 9mm wide 48T pulley. The axle has a double slot for the driveshaft pin for lightness and long life. Spring steel, CVD type, drive shafts connect the rear shaft to spring steel wheel-axles with aluminium quick-change levers. A very durable and long lasting drivetrain.

The new rear lower wishbones have a hollow style design with closed bottoms for aerodynamics and separate top mounted moulded plates. The lower rear arms hold the link for the rear anti-roll bar and the alu mounting plate of the rear shocks. This plate moves the shock mounting position to the outside for improved geometry. Nylon clips are used on the lower rear pins to change wheelbase.

The rear floating body mount which is mounted on the up-rights with 2 arms is centred by a carbon-fibre and steel guider. The mount has 4 positions on each side to choose from, depending on body shell used and traction available. The threaded holes on the end of the body mount give the option to add further body-supports.