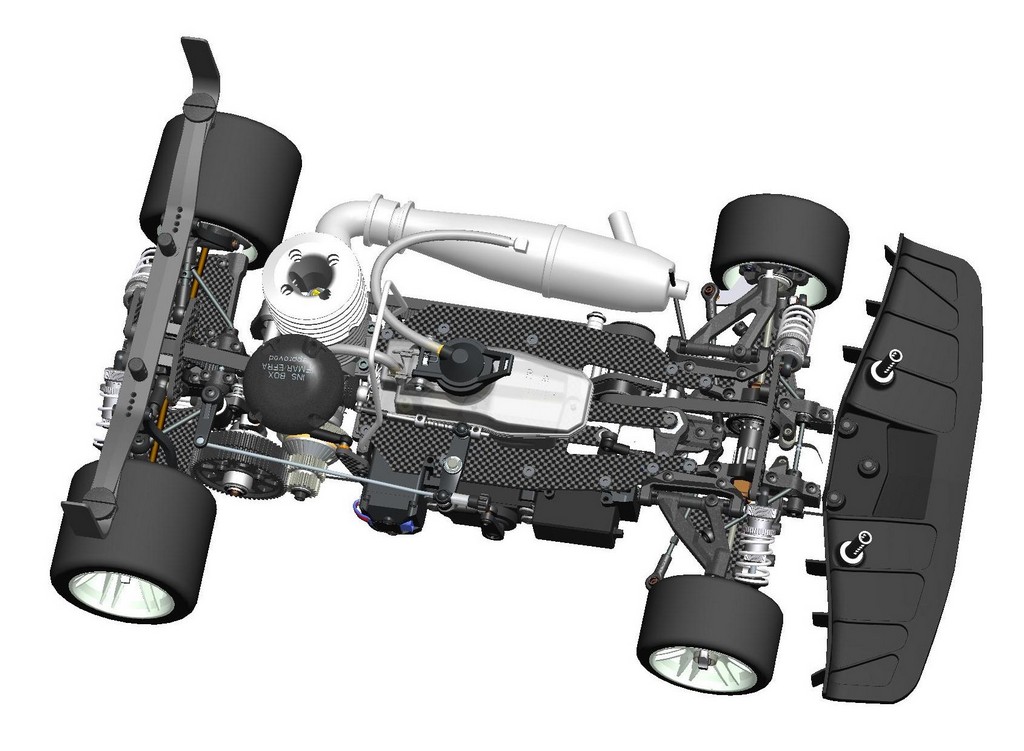

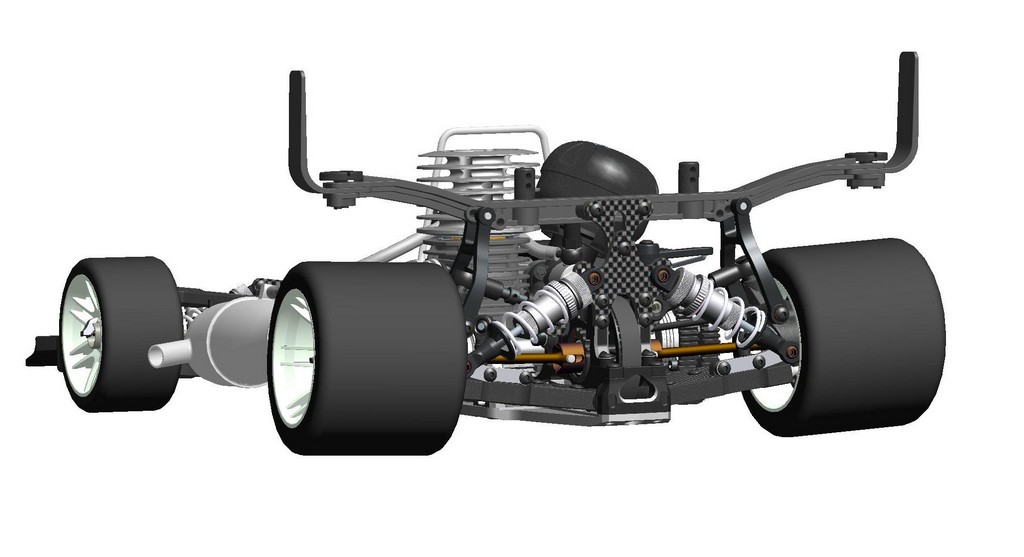

The Serpent Viper 989 is the latest development of Serpent on the 1/8 gas market. Serpent has been the driving force for decades and the Viper 989 is the latest interpretation of a high performance race car based on that experience, combined with the latest insights on weight, weight distribution and flex.

The Serpent Viper 989 is the latest development of Serpent on the 1/8 gas market.

Serpent has been the driving force for decades and the Viper 989 is the latest interpretation of a high performance race car based on that experience, combined with the latest insights on weight, weight distribution and flex.

As the inventor of the Centax clutch, the 2-speed gearbox and many other things that are now industry standard, we also integrated some new solutions on the suspension.

Another major point of development was to reduce weight, reduction of vibrations and ease of set-up and maintenance.

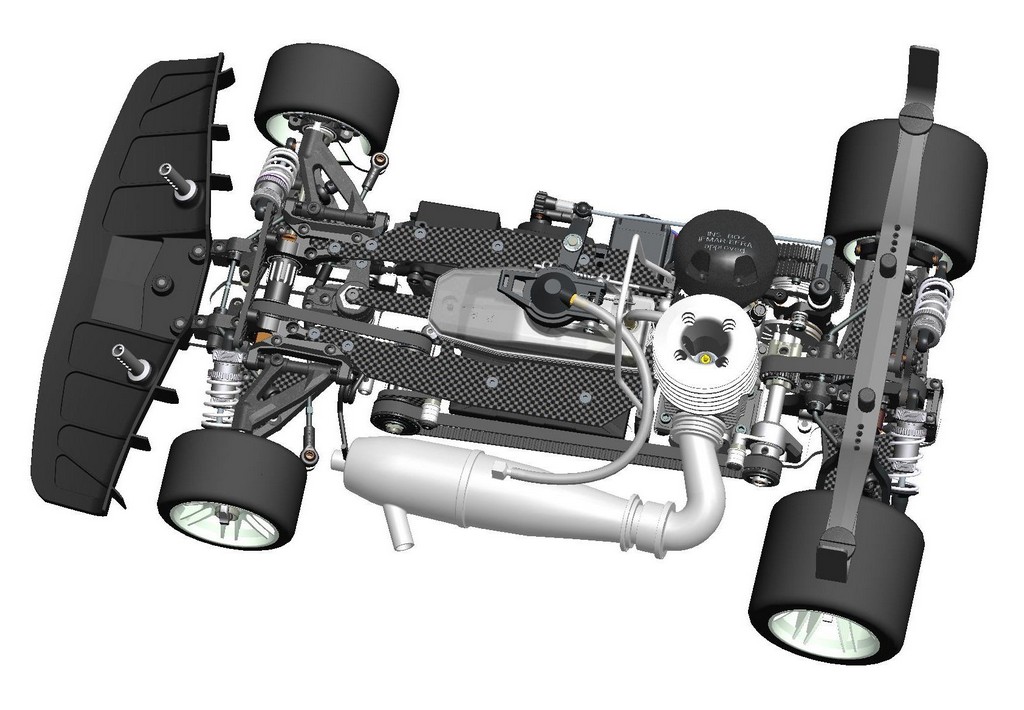

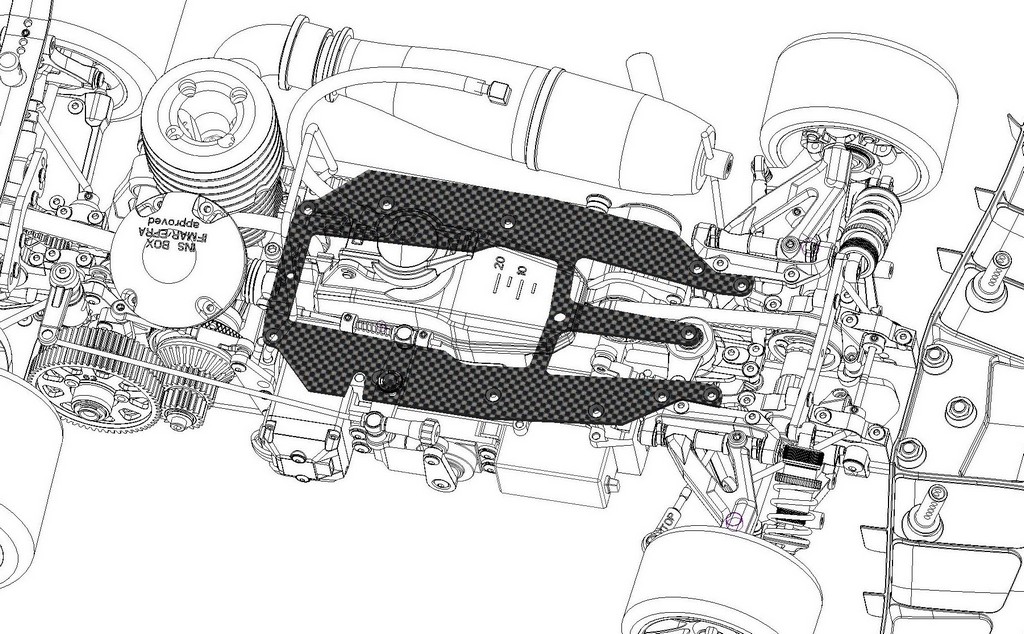

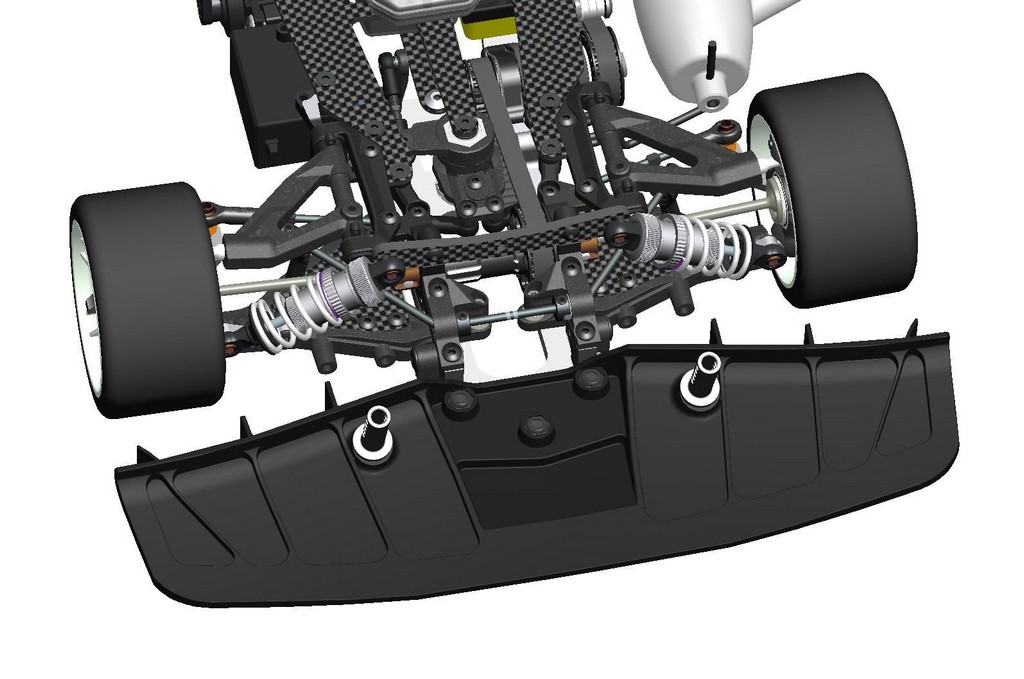

Ultra-narrow chassis with improved flex characteristics. The chassis is milled down in less load-stressed areas to make it as light as possible and still remain stiff in areas where needed.

We kept the possibility to have a weight in the very bottom which is easily adjustable in it’s position.

At the same time we improved the way it is it mounted to reduce vibrations by using a carbon weight bridge which is mounted in anti-vibration rubbers.

We also have added 2 more locations for another weight, one underneath the engine and another one underneath the servosaver.

The central weight bridge allows the use of max 3 weights

All weights are mounted as low as possible to improve the center of gravitiy

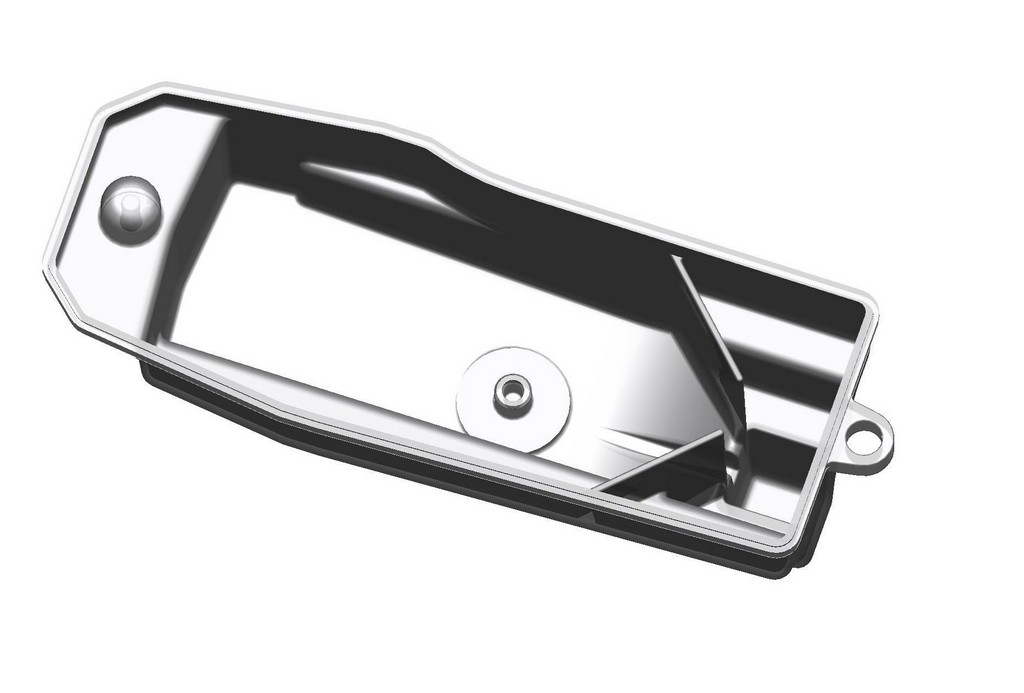

The one-piece plastic radiomount is replaced by a 2-piece aluminium construction. It is lighter than the plastic one, and at the same time it improves the flex characteristics and the accuracy of mounting the radioplate.

The rear bulkheads are now also connected to the rearplate to improve the stiffness as well as reduce vibrations.

The bulkheads are machined excessively to get the perfect balance between weight and strength

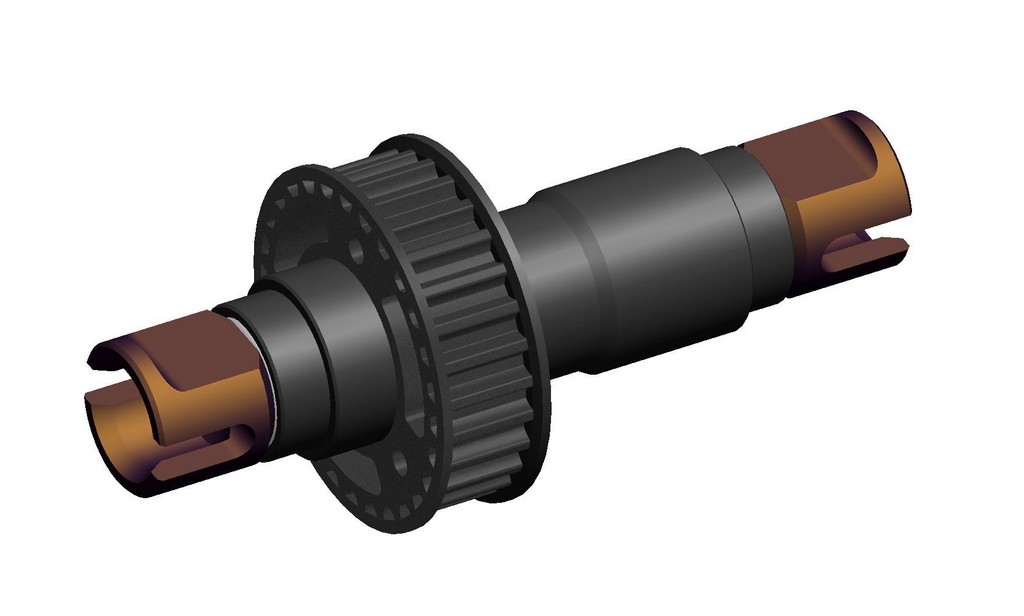

Their shape now allows the removal of the rear solid axle without removal of the 2-speed shaft and belt

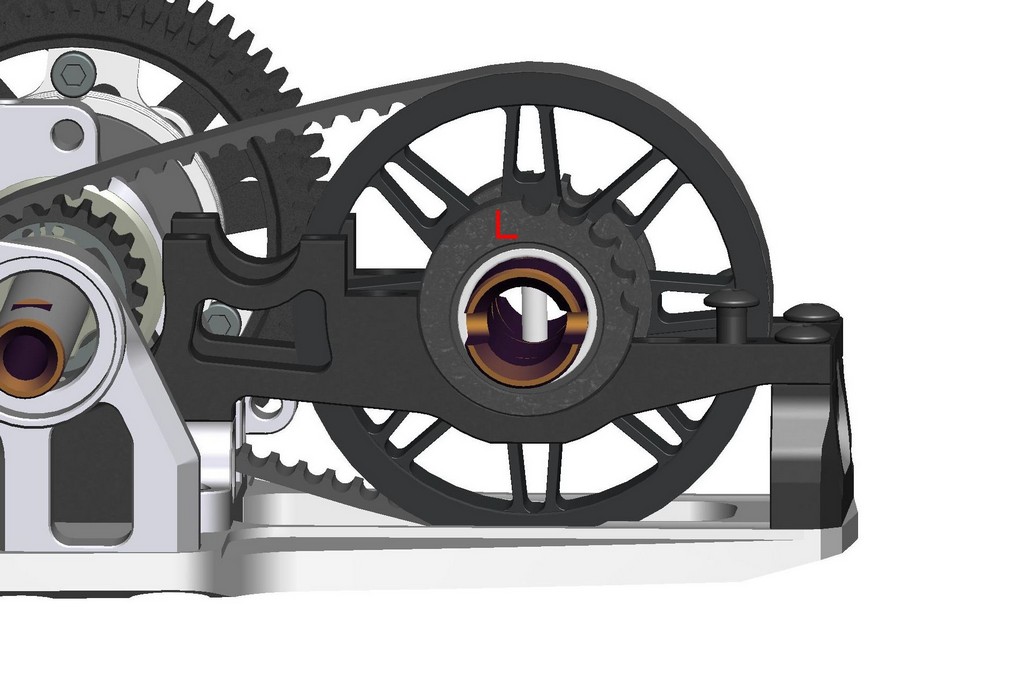

The brake now features a 2.5mm thick disc with improved ventilation and braking stability

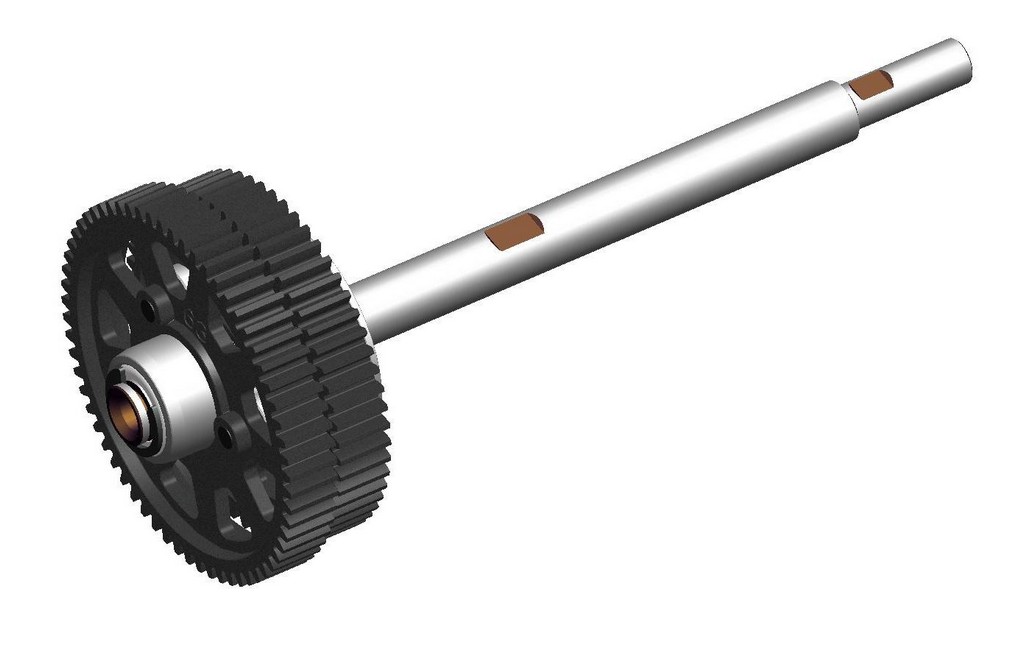

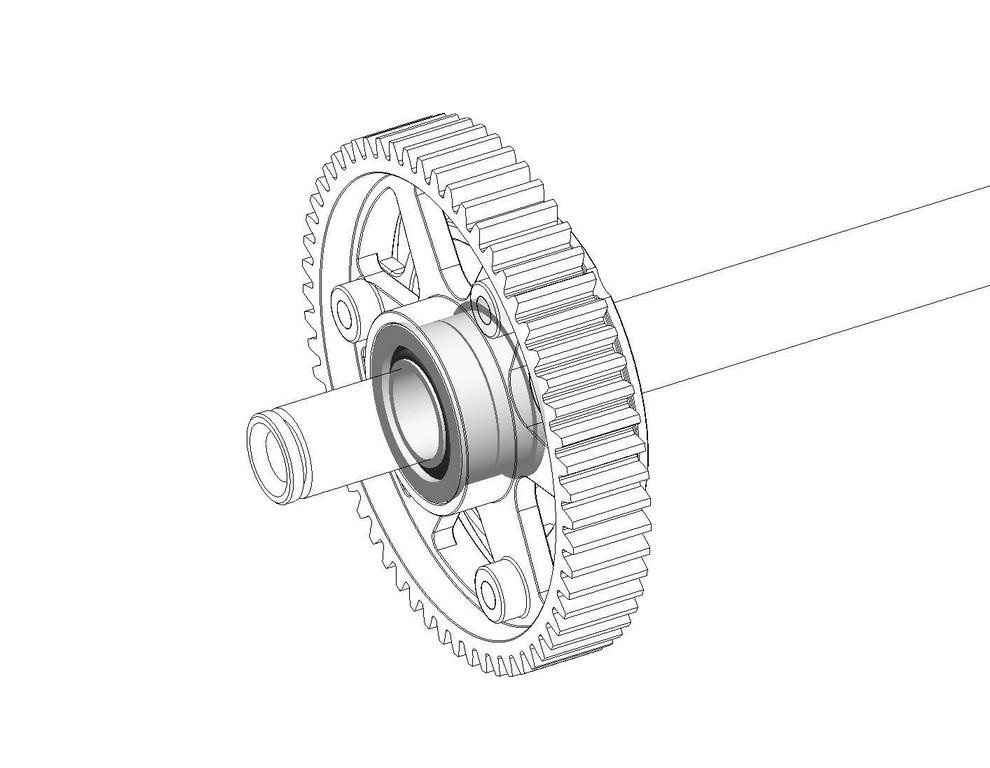

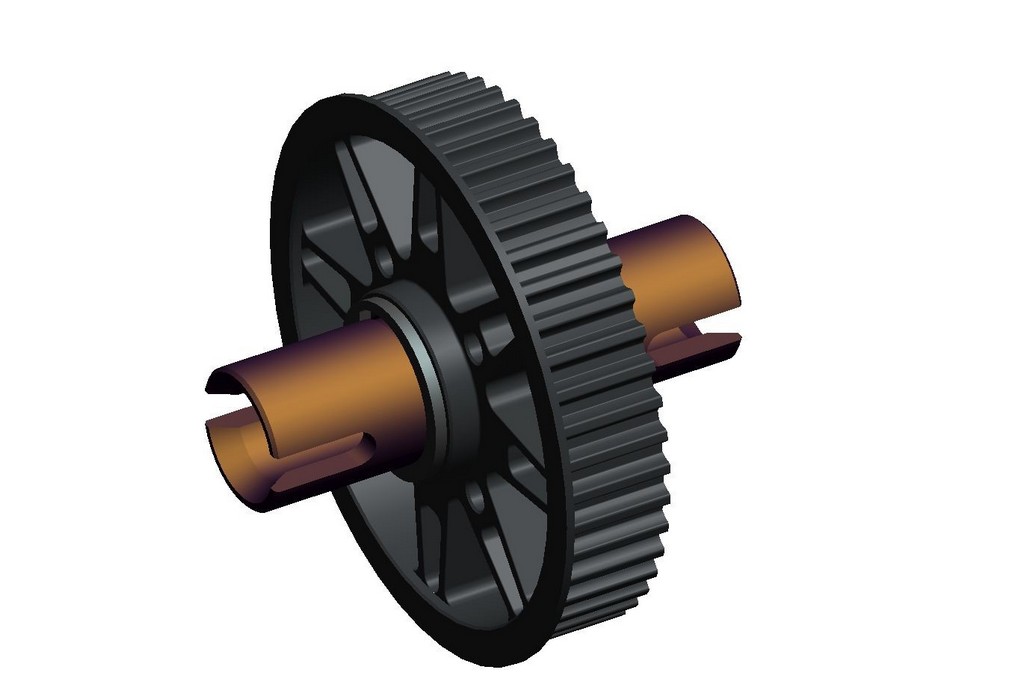

The pulley adapter is a much lighter construction for better inertia and improved acceleration

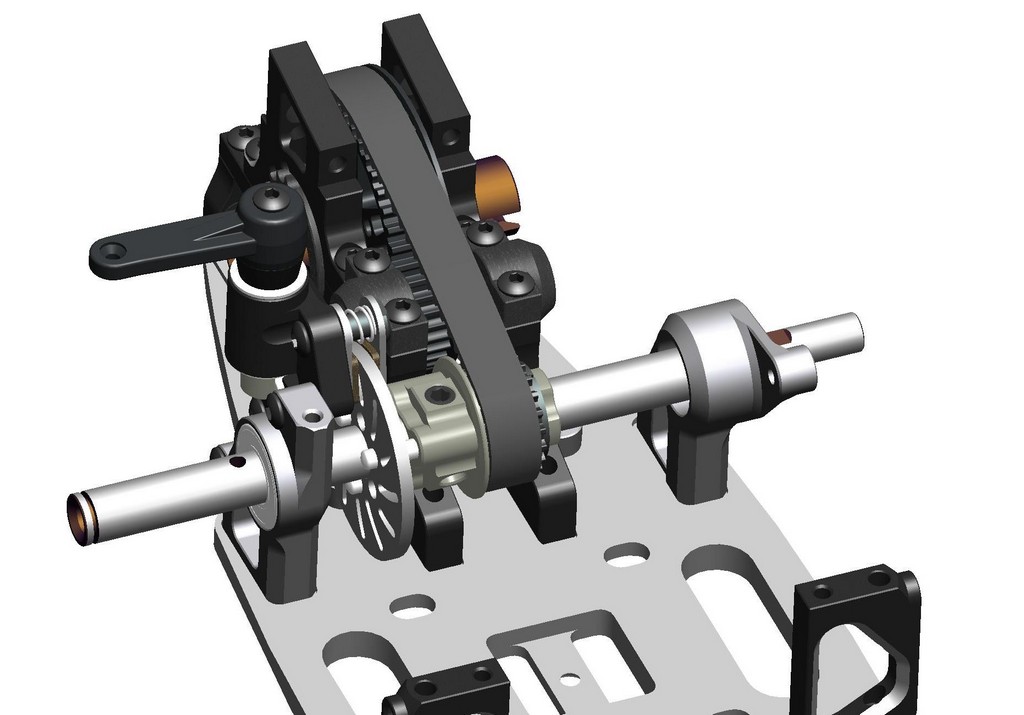

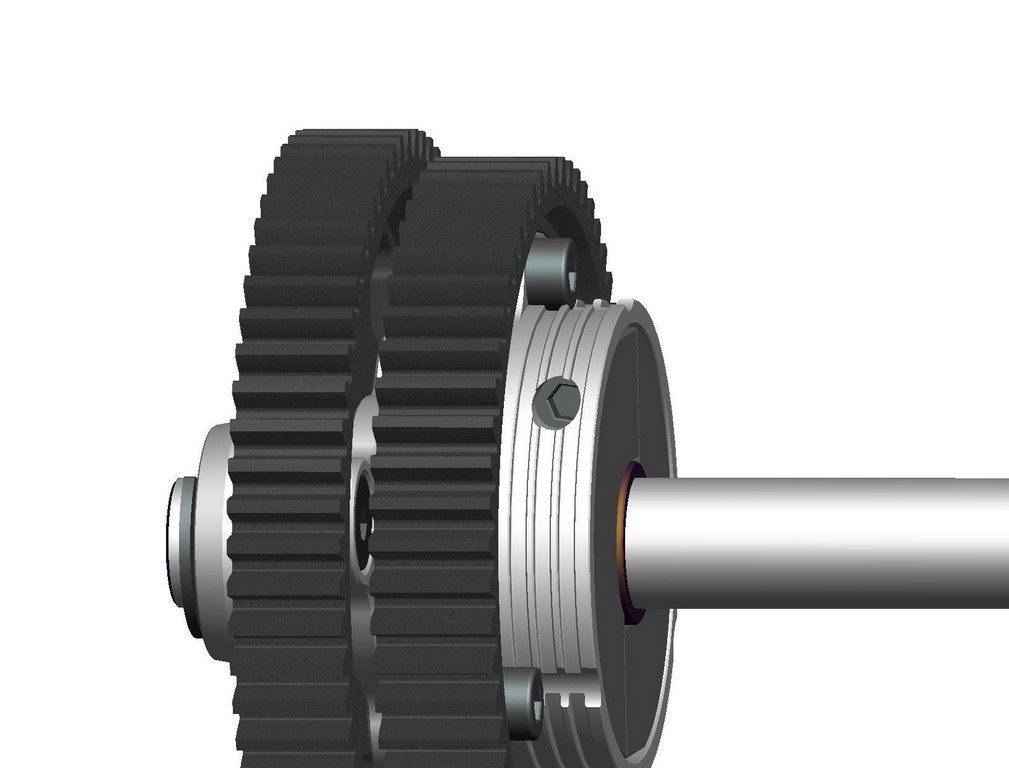

A new shorter internal gear ratio of 2.4 helps acceleration and increases the active range of the overall gear ratio. Using 19/24 now is almost like 18/23 on the 988.

Also the overdrive has changed slightly to have the perfect rear/front drive balance with ENS and EFRA hand out tires

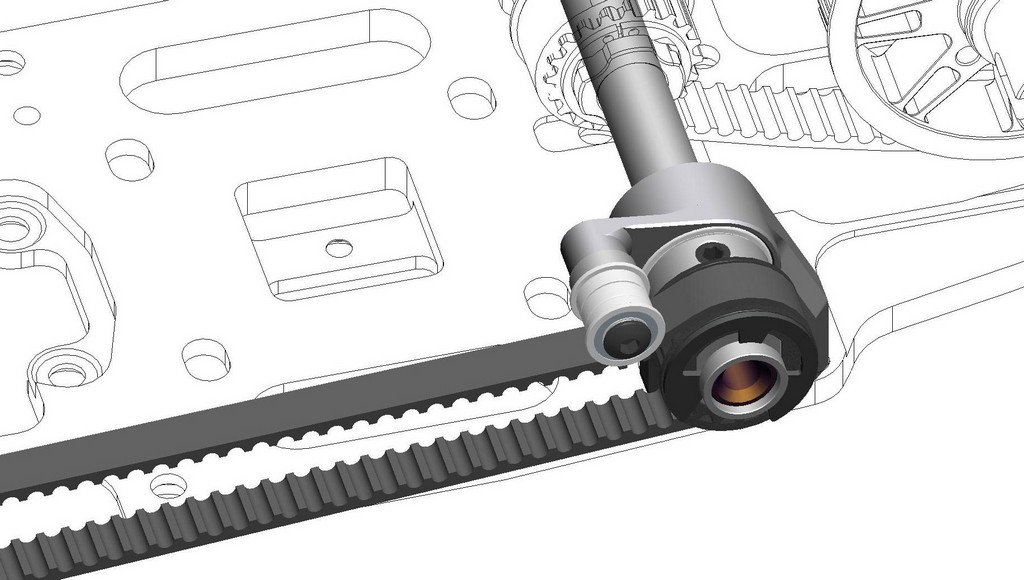

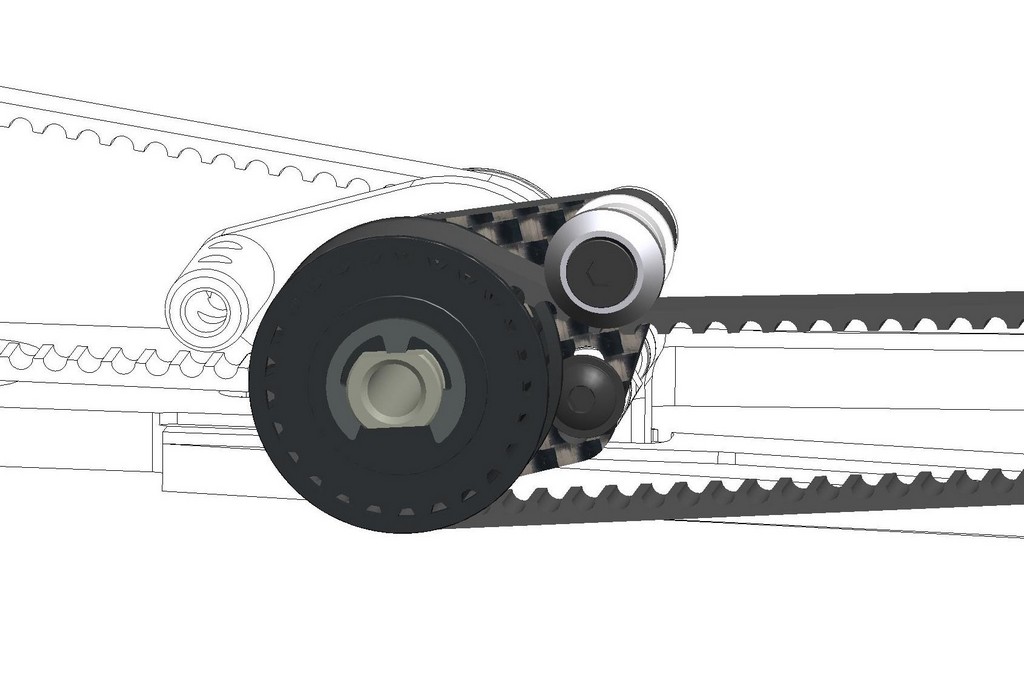

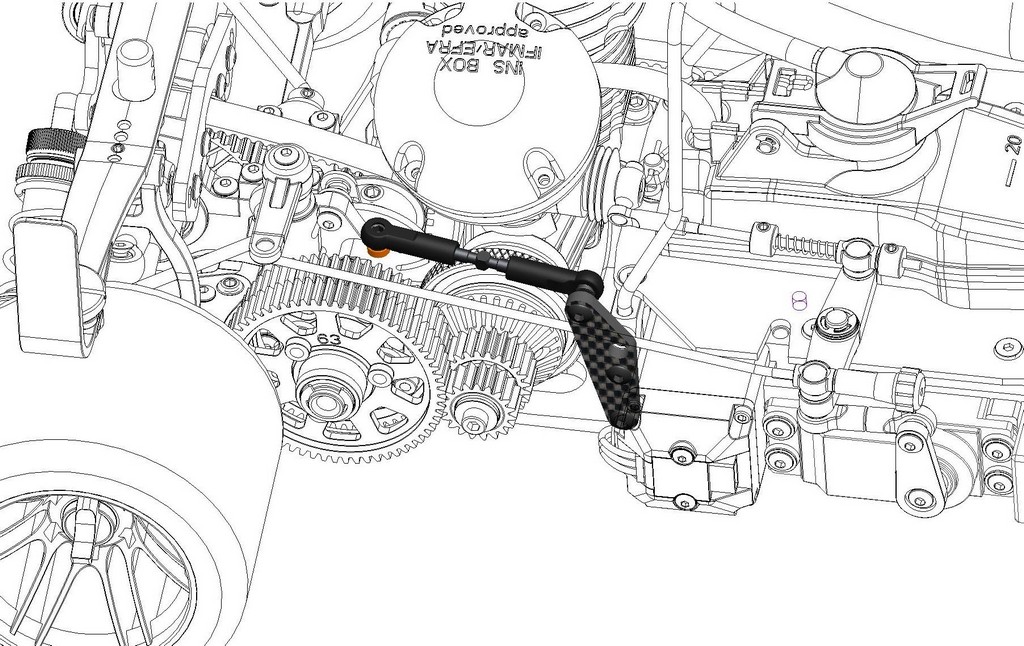

New side belt tensioners improve clearance with the engine manifold.

It also reduces vibrations on the sidebelt.

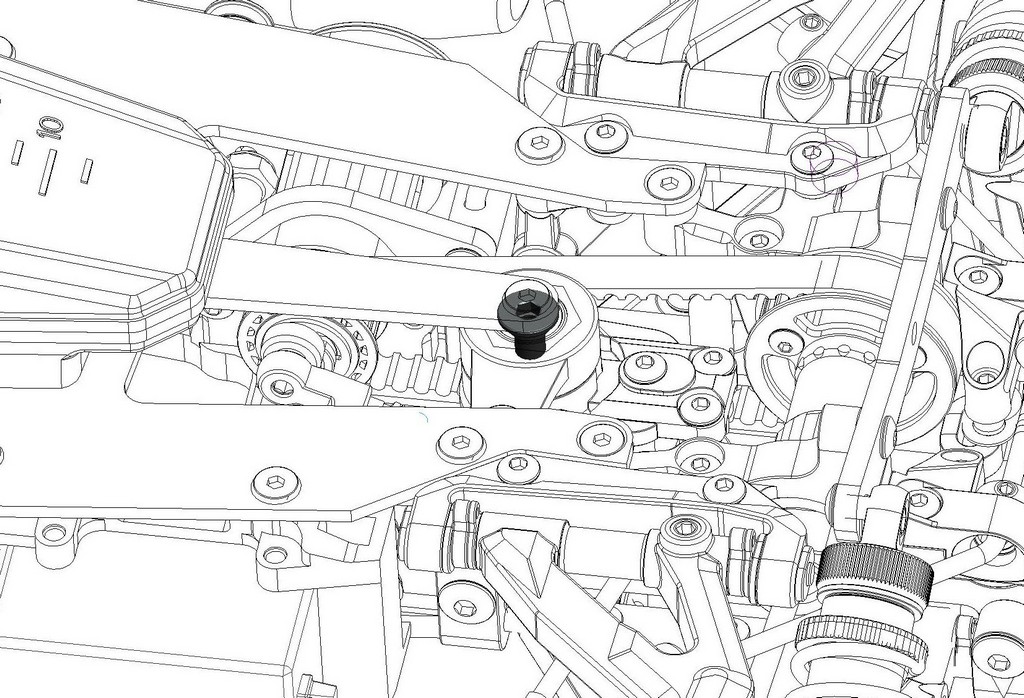

Adjustment is easily done on the midshaft

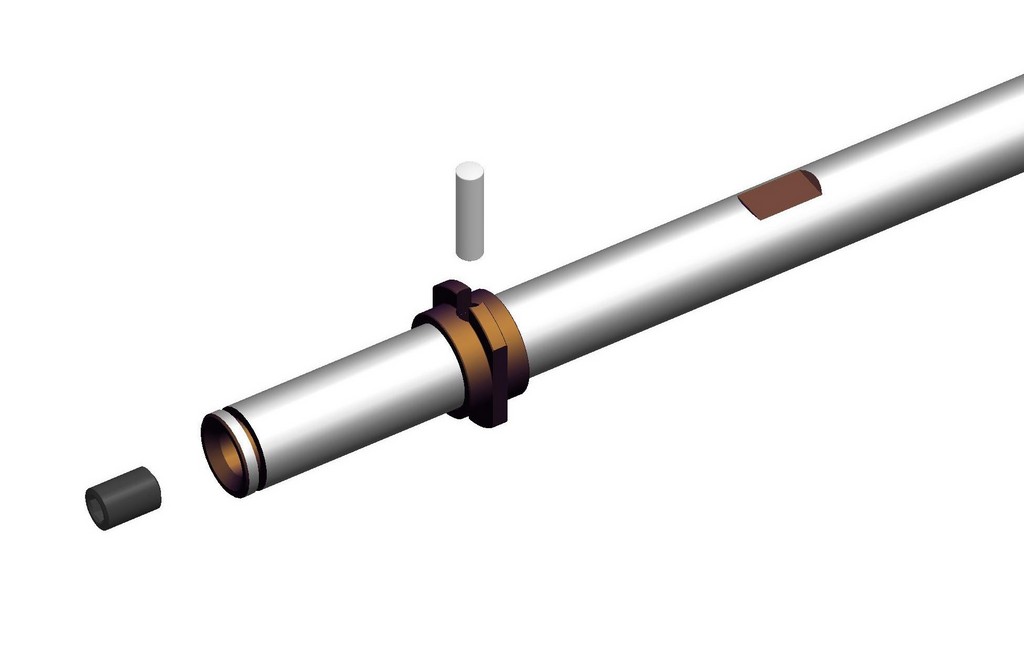

The new super-light midshaft assembly also acts as adjustable belt tensioner as well as pipe wire holder

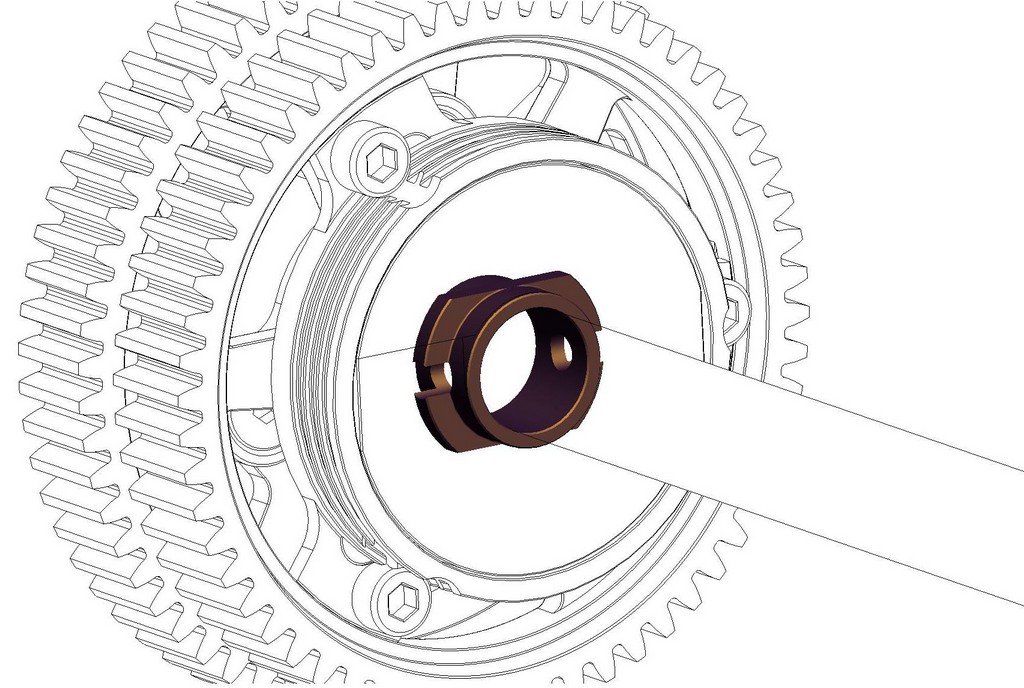

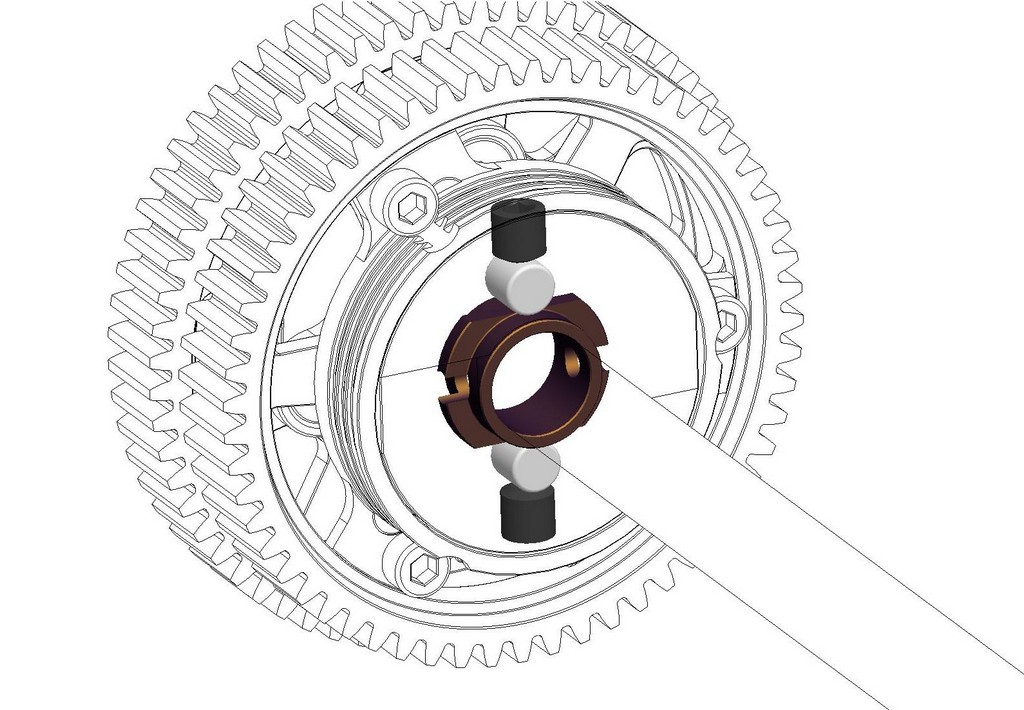

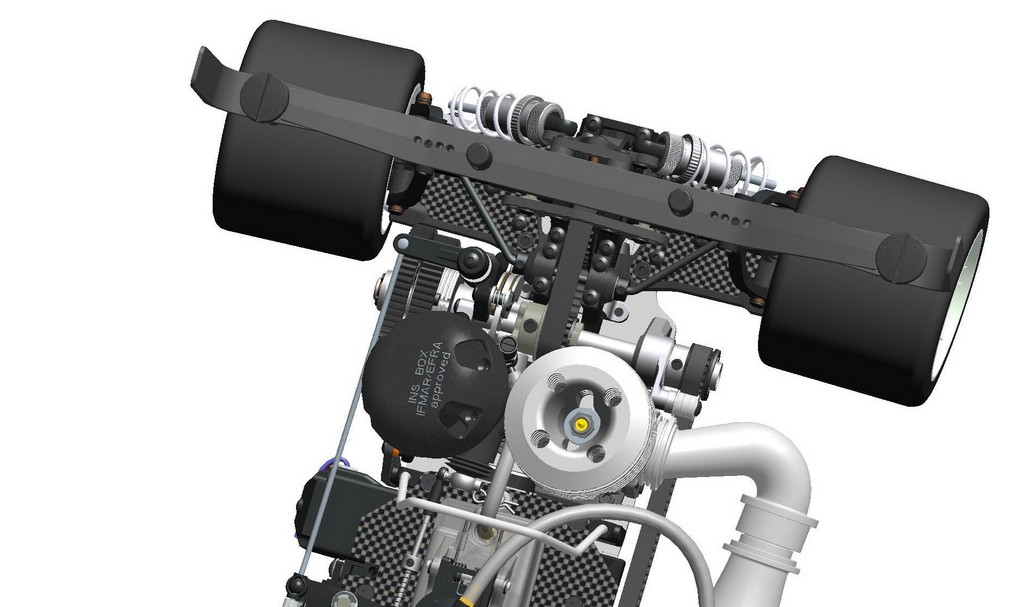

The completely new gearbox has less inertia than the one from the 988. This improves acceleration.

Despite being lighter it offers new features to improve reliability and consistanty

A much longer ramp for the roller avoiding locking of the second gear even with excessive wear on the shoes

M4 setscrews for gap adjustment to help keeping the gap constant

2 bearings in the second gear “bell” for better truth of rotation and balance

Easy access for adjustment from the outside

2nd gear adapter is locked in position to avoid binding and deliver constant performance of engine and gearbox

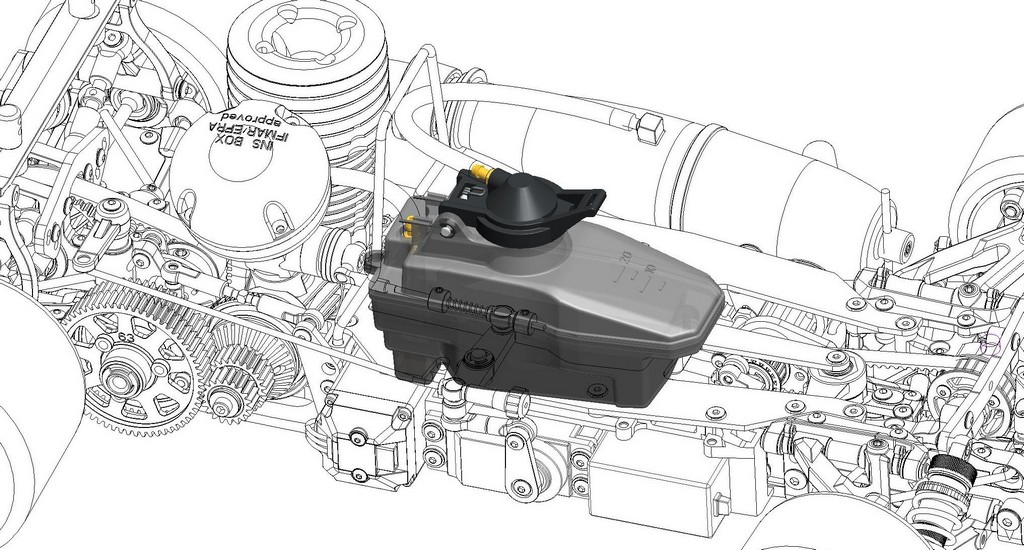

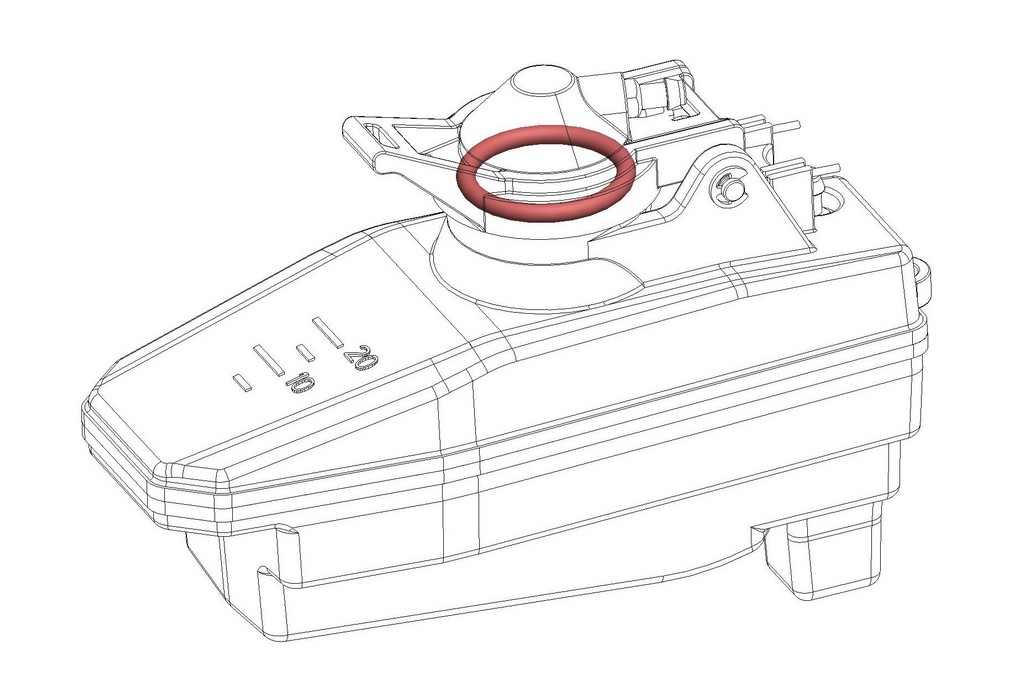

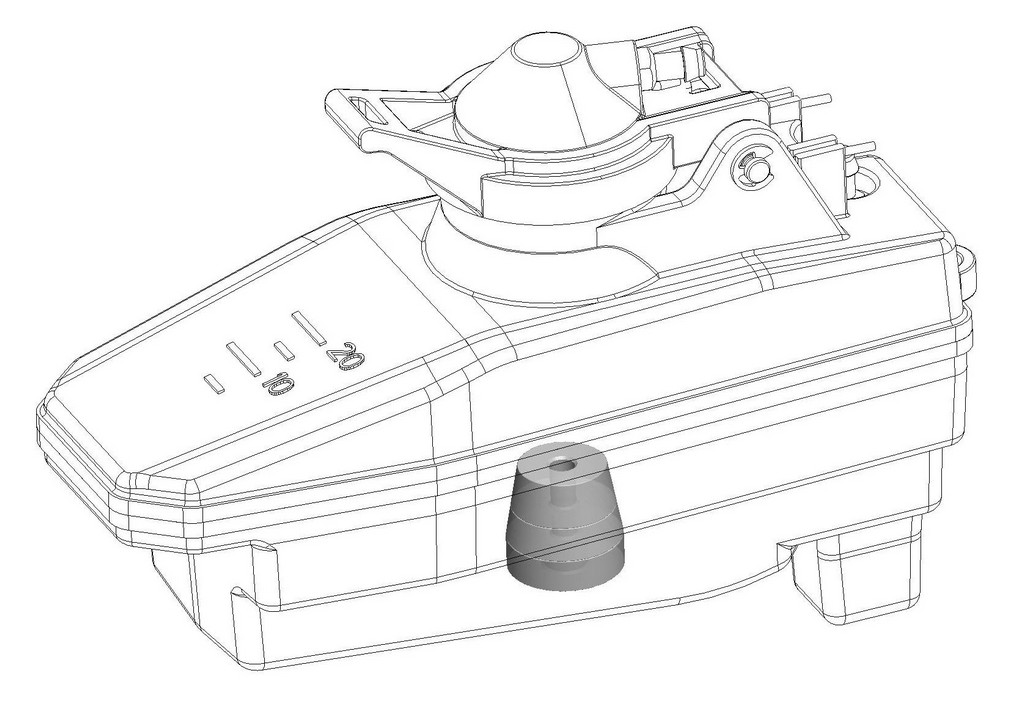

New shaped fueltank mounted on top of the radioplate.

The new tank is more consistent in adjustment no matter if it’s full or almost empty.

The new tank seal keeps a higher pressure and keep things dry and clean

The cap of the tank is higher to allow even faster refueling.

The volume of the tank is 125cc and needs to be adjusted by the user to perfect volume inside the rules by using inserts

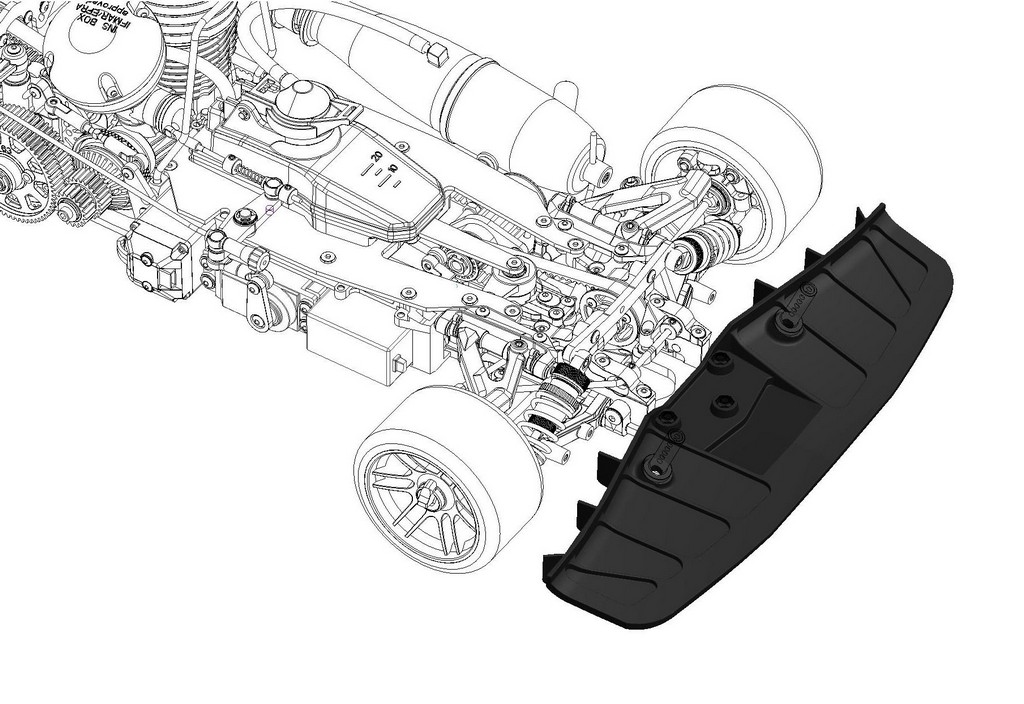

New superlight, one-piece bumper for improved aerodynamics.

No inserts anymore to keep it simple. Excessive testing of different shapes lead us to this design to have the best balance of front end grip on high as well as low speed and hairpins

New mounted rear chassis stiffener to allow for easier removal of the radioplate

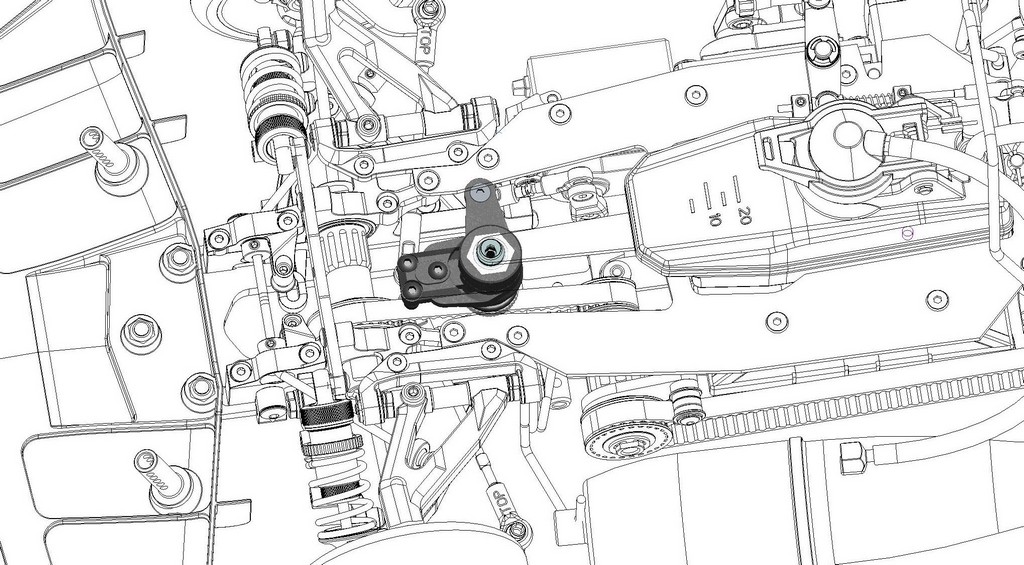

New way of mounting of the servosaver. If the radioplate is not mounted, the servosaver still stays in place

New shaped radioplate. This shape has been found to provide the best flex characteristics

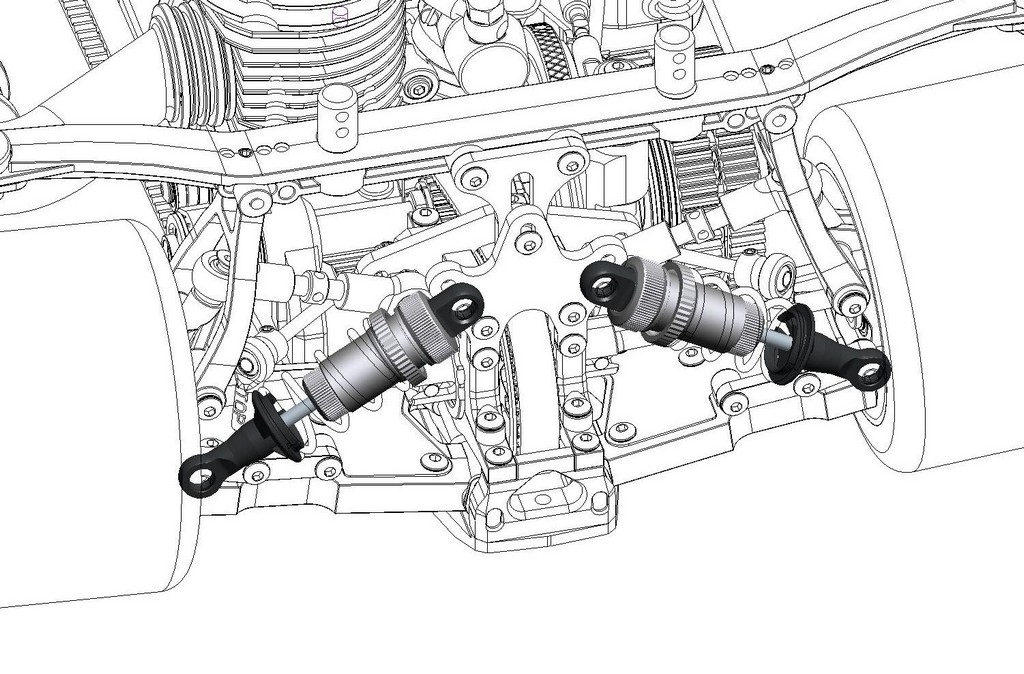

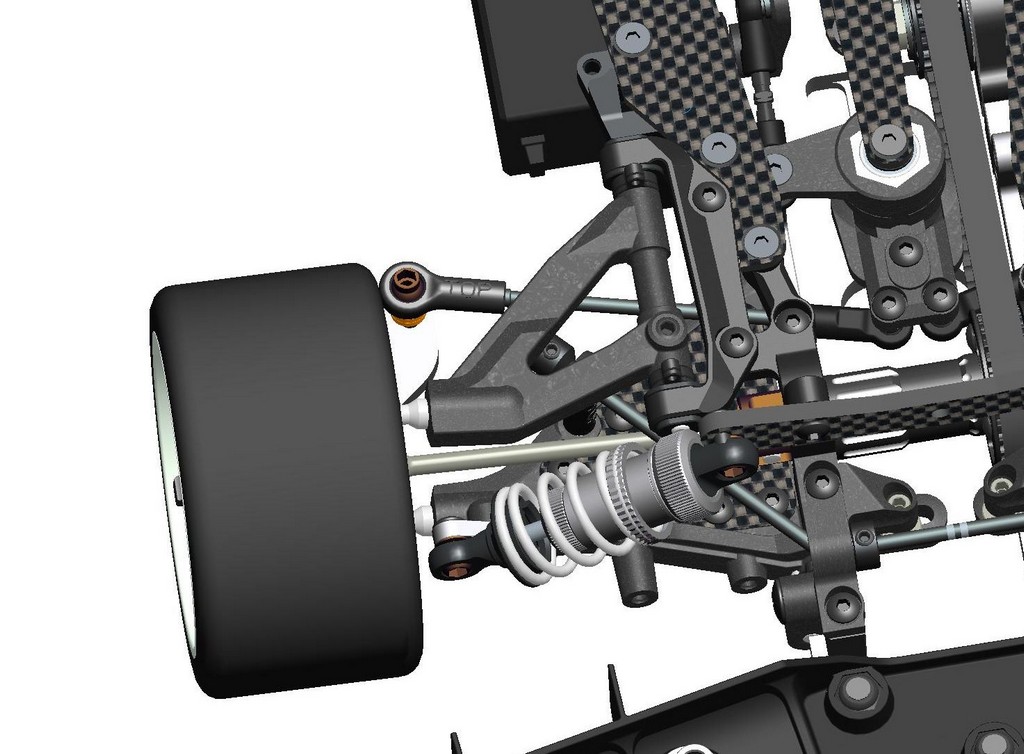

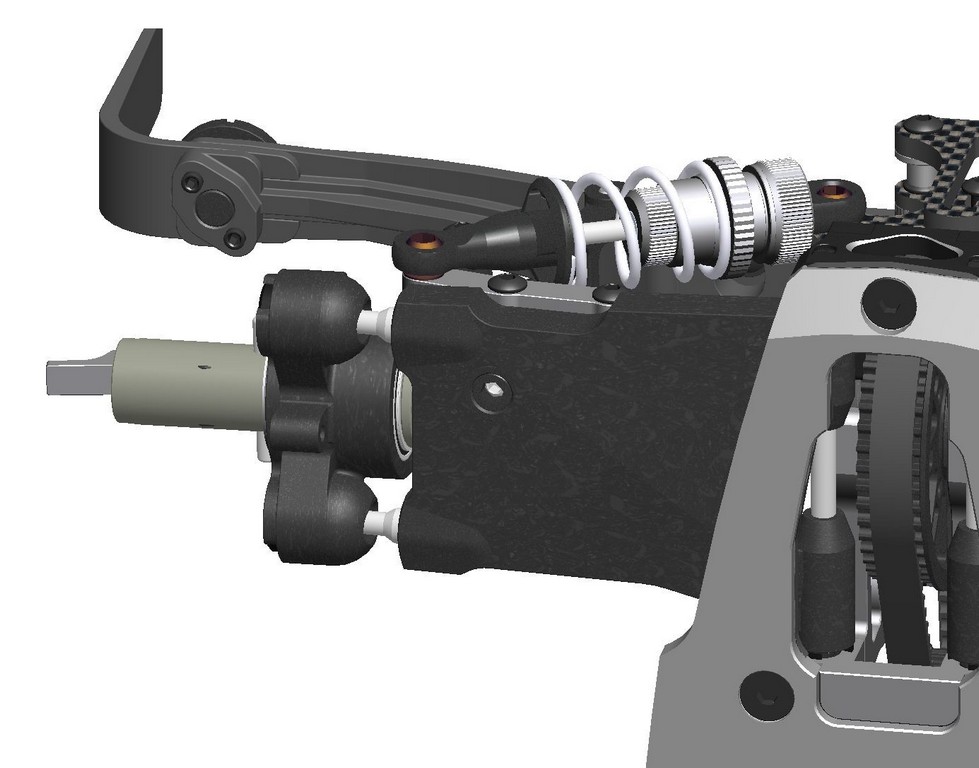

New improved shockabsorbers for the ultimate grip

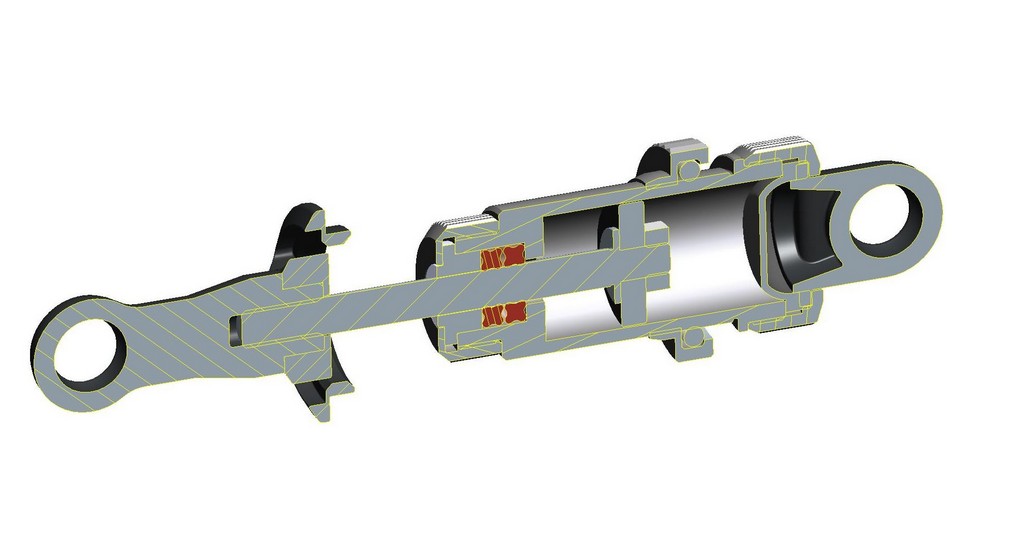

The single most important new feature are probably the shock-absorbers. A lot of attention has been payed to minimize friction and jamming.

Testing has also shown that a slightly smaller bore works better.

On the rear of the car we also increased the total length for extra stroke and better progressivity

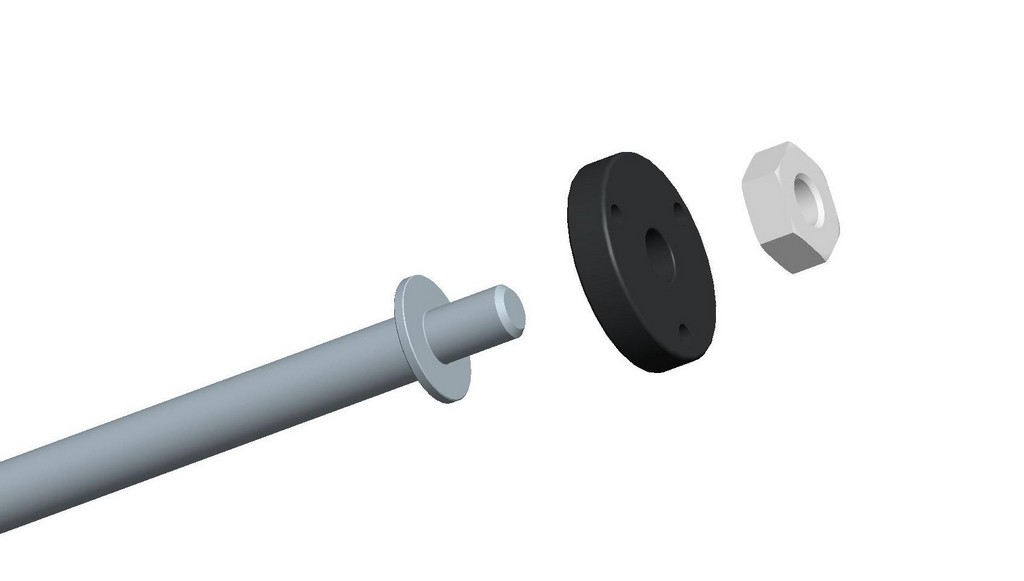

The piston is fixed onto the shaft with a nut. No clipses or shims.

On top of that we payed a lot of attention to the bottom seal. 2 X-rings and a long bushing provide that extra bit of low-friction sealing that keeps the oil inside and the dirt outside

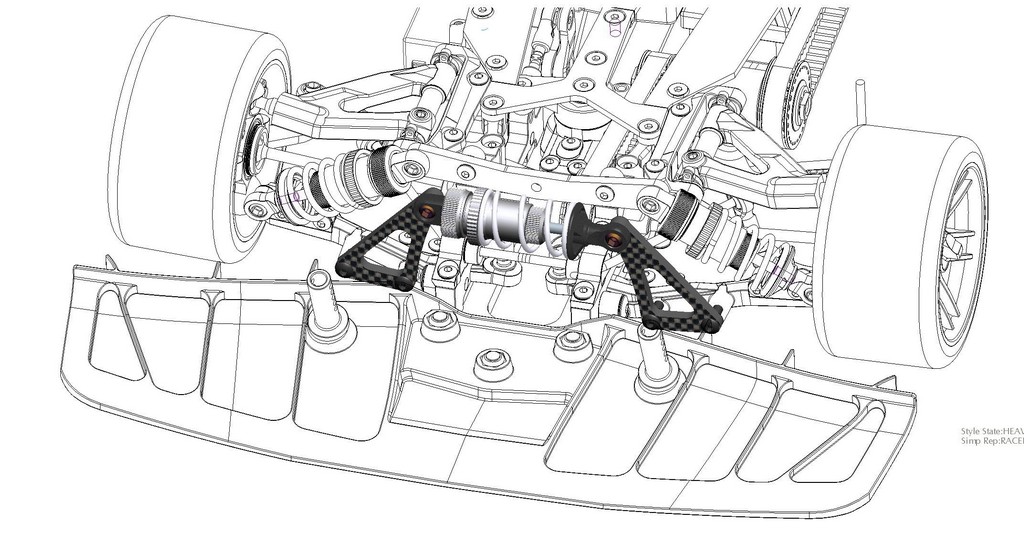

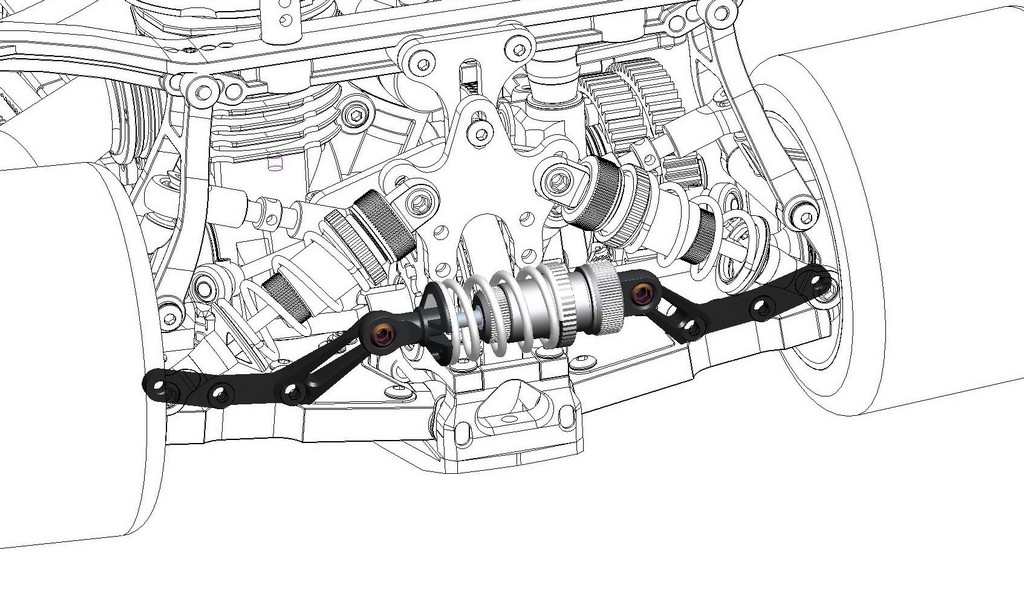

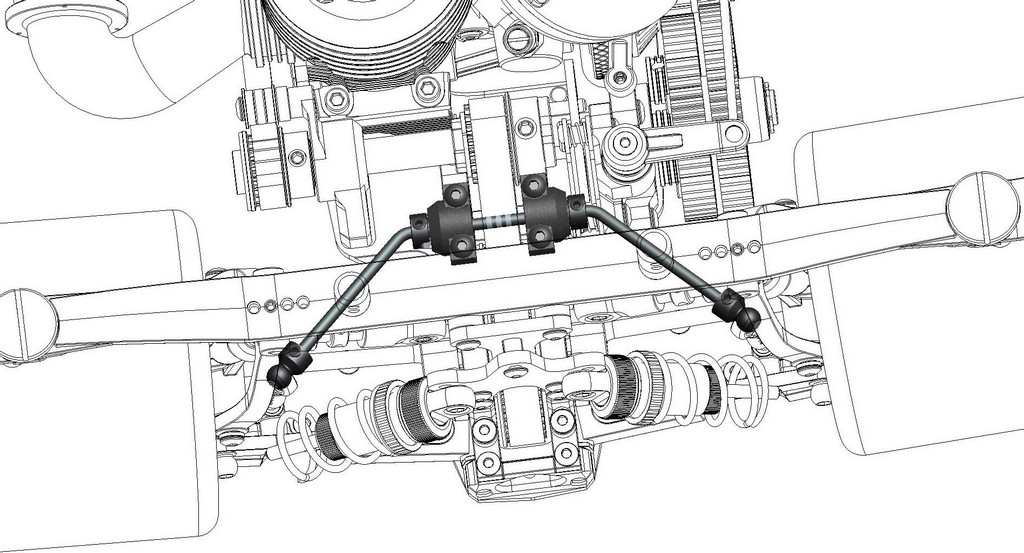

As an option the 989 offers a heave-damper setup in the front as well as the rear.

n this way it is possible to change heave adjustments more or less independent of roll adjustments.

As an example it is possible to have a very light roll damping combined with a very high heave damping, something which is not possible with a classic suspension.

The third damper can be used to only alter the damping characteristics without a third spring, but also to add a spring to alter spring rates for heave

The front and rear heave sets are available as an option.

Other main specs

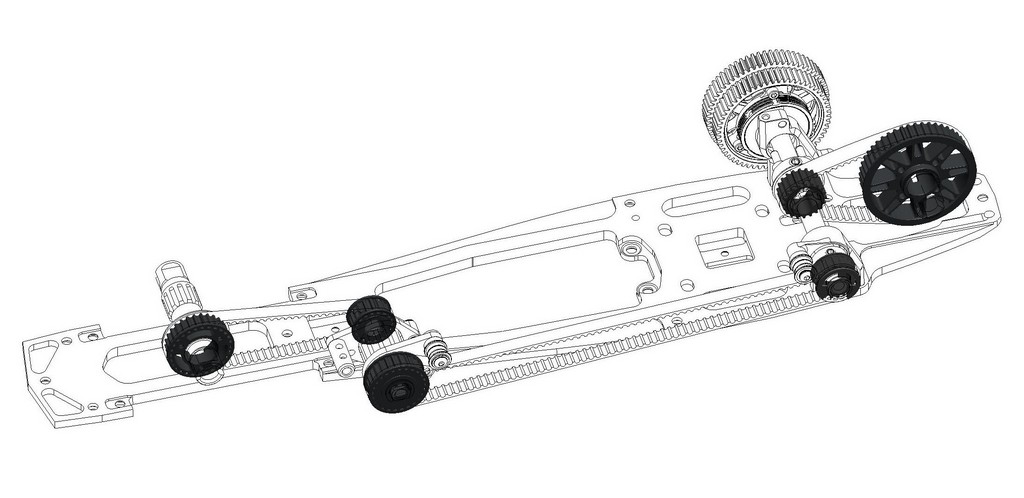

- 4wd belt-driven race car

- Serpent spring steel axles with quick change system for the wheels

- Front and rear spring steel cvd shafts

- NSK bearings for the transmission

- Low friction belts and ball raced belt-tensioner

- Black anodized front shaft with one-way bearings and narrow rear solid axle

- super low inertia 2-speed gearbox

- Independent suspension with hydraulic low-friction shock absorbers

- Ball raced front and rear anti-roll bars

7075 T6 Aluminium 5mm chassis plate

The 5mm aluminium chassis has perfect symmetrical shape for even flex and weight distribution. The ultra-narrow chassis is very light, while it still remains strong in critical places. The Viper 989 logo is laser engraved.

The newly developed front bumper is a very light and easy to use design.

The strong aluminium front body posts are eccentric, to allow movement of the body a few mm forward and backwards to optimize steering and downforce.

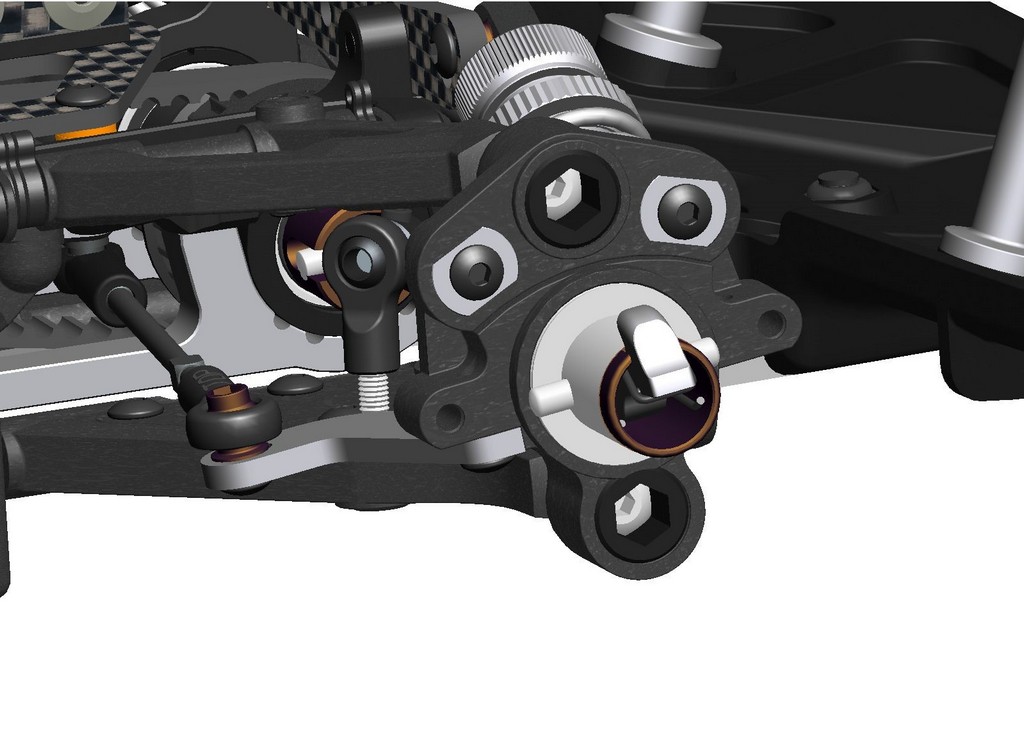

The steering blocks, which are equal left and right, offer a system to change the axle position to a “trailing” or “leading” position, and the ability to change the kingpin-inclination and offset. This allows multiple options to fine tune steering balance in all phases of the corner. The steering block features an aluminium plate to connect the spring steel track-rods. They have 2 Ackermann options.

Optional carbon fibre disks can be mounted on the side of the steering blocks and uprights for aerodynamic adjustments.

The long durable front lower wishbones are in a new hollow type design with closed bottom for improved aerodynamics and have separate top mounted moulded inserts. An aluminium shock mount plate is screwed onto the lower wishbone. This allows the shock attachment point to be placed further outwards improving shock motion. The front lower arms are mounted to the front brackets with nylon holders. The kit includes 2 versions: in and out. This system also enables quick and easy front drive shaft maintenance.

The left and right interchangeable upper arms are mounted with 3 position nylon suspension pin inserts. The 3 position inserts allow camber-change adjustments and are held in place by the anodized aluminium top brackets. Below the top brackets, spacers can be used to change their angle or height. Caster is adjusted with clips on the upper pivot pins. The same clips are also used on the lower pivot pins to change wheelbase.

The wire type front anti-roll bar is ball raced. It is easy to change and adjust due to the open front end design. The standard wire is 2.5mm and 2 optional thicknesses are available. The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The steering blocks are connected to the arms with spring steel 8.5mm pivot balls, which run very smooth and well protected in nylon cups, and are easy to adjust with a 2.5 hex tool.

The black anodized aluminium front axle has Japan made one-way bearings. Spring steel drive cups connect to the long and thin spring-steel drive shafts with CVD system. The ball raced spring steel wheel axles have aluminium quick-change levers. The open front end design allows for very fast and easy removal of the front axle and driveline parts.

The central mounted seervosaver allows easy and fast Ackermann adjustment. The servosaver features a top mounted insert which can be used in 3 positions. Another 2 Ackermann positions are available on the steering blocks.

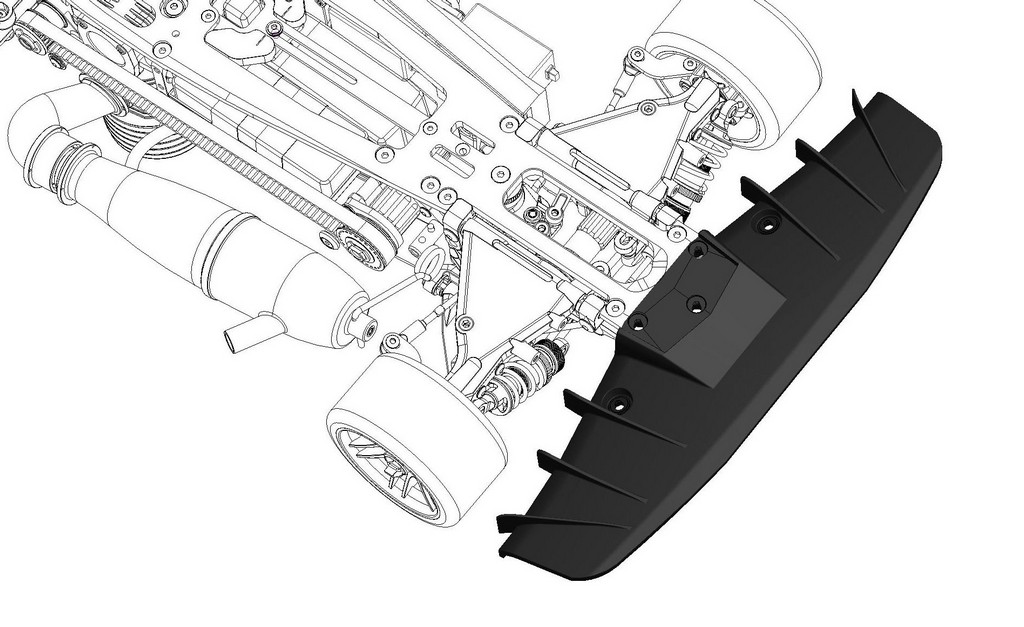

The rear end construction with aluminium brackets is a very open design, which allows for easy of maintenance and cleaning. Dis-assembly requires the removal of only a few screws. Replacing a belt if needed, is a simple task. The eccentric bearing holders on the rear shaft allow adjustment of belt tension. The whole rear end can be removed as one unit from the chassis by removal of only a few screws.

The wire type rear anti-roll bar is ball raced. It is mounted in the rear bearing blocks and is easy to change and adjust. The standard wire is 2.5mm and 2 optional thicknesses are available. The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The narrow solid rear axle in Serpent spring steel has a lightweight 9mm wide 48T pulley. The axle has a double slot for the driveshaft pin for lightness and long life. Spring steel, CVD type, drive shafts connect the rear shaft to spring steel wheel-axles with aluminium quick-change levers. A very durable and long lasting drivetrain.

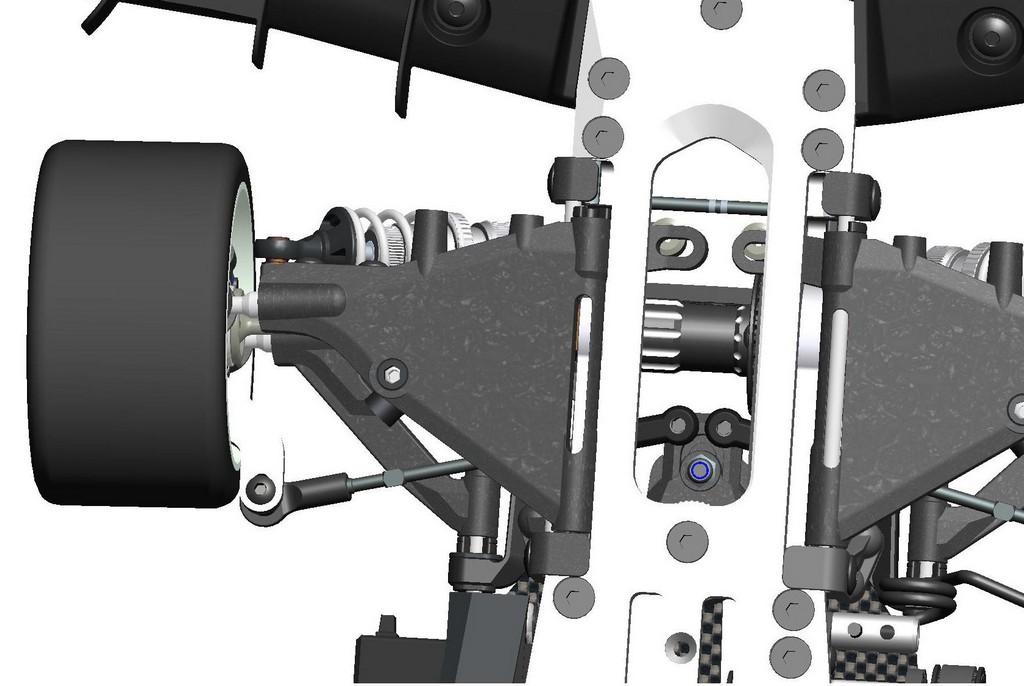

The new rear lower wishbones have a hollow style design with closed bottoms for aerodynamics and separate top mounted moulded plates. The lower rear arms hold the link for the rear anti-roll bar and the alu mounting plate of the rear shocks. This plate moves the shock mounting position to the outside for improved geometry. Nylon clips are used on the lower rear pins to change wheelbase.

The durable composite uprights hold the ball raced wheel axles, with aluminium quick-change levers. On top of the up-right spacers can be added under the pivot ball to change roll centre and camber change.

Optional carbon fibre disks can be mounted on the side of the uprights for aerodynamic reasons. The rear uprights are connected to the arms with spring steel 8.5mm pivot balls, which run very smooth and well protected in nylon cups, and are easy to adjust with a 2.5 hex tool.

The adjustable rear upper camber links mount to a 4 position rear carbon fibre camber plate.

The rear floating body mount which is mounted on the up-rights with 2 arms is centred by a carbon-fibre and steel guider. The mount has 4 positions on each side to choose from, depending on body shell used and traction available. The threaded holes on the end of the body mount give the option to add further body-supports.

Optionals

A large selection of optional parts is available to even further improve performance, speed, weight and looks.

www.serpent.com/903018

Communications

- Website

- Promopage

- Facebook page

- Viper 989 Facebook user group

- Serpent Advanced user Manuals pages

- YouTube video’s

- Online set-up sheets

- Support from distributors, dealers and team drivers worldwide

Merchandising

A nice selection of shirts, sweaters, jackets, caps, bags, tools and decals.

Design

Serpent Viper 989. Designed by Michael Salven.

With great help from all team-drivers and 988 drivers!