- Brand:

- Serpent

Product Type:- Electric Cars > 1/10 offroad

Serpent SRX2 Gen3 “Carpet Spec” 1-10 Electric Powered 2wd Racing Buggy The Srx-2 Gen3 has been completely re-designed from the ground up. The customers, racers, and fan favorite trolls have shared their glories, opinions, and pains about the previous SRX-2’s. We were open minded and willing to meet every expectation to push the boundaries of our product and the 1/10 2wd Market. The new SRX-2 needed to be slimmer, stylish, tougher, easier to work on, and above all else Faster. With over 85% of the parts being new, all the while, still being able to use most all previous SRX-2 parts, this car is an absolute masterpiece of construction. You can build it to any configuration you wish, new and/or old. Here at Serpent’s Secret R&D office, we are un-rivalled in our interest to win, and feel, this car will take you to more checkered flags than any previous SRX-2model we have ever made, Guaranteed.…!!!!!

> Downloads

10-04-20 Manual SRX2 Gen3 carpet 18 MB Download

10-04-20 Ref guide SRX2 Gen3 carpet 22 KB Download

> Description

This increases ground clearance, while decreases the loss of forward momentum. It also keeps you from playing Lawn Darts off any pesky jumps your local track can throw at you. Talking about pesky jumps, the wooden kind, those ones you find on so many carpet/turf tracks around the world. Finding the invisible speed is only for the master magicians. Thankfully, we have one in house working diligently day and night, on and off the race track, to enhance your racing experience.

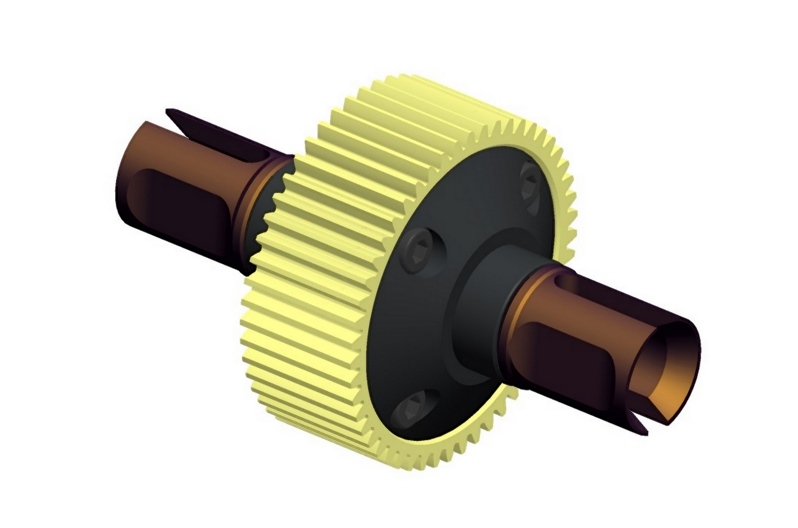

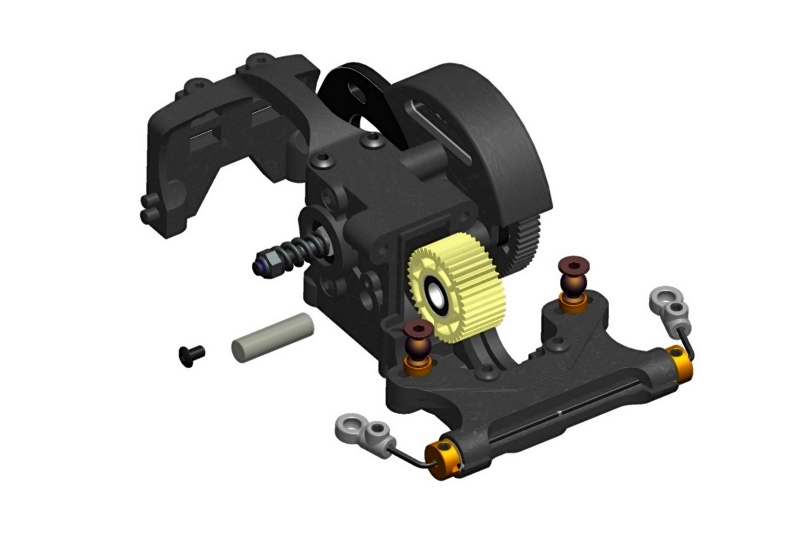

Included in the Srx2-Gen3 Carpet spec kit, is a super compact and light weight Gear differential. The diff can be run with 2 or 4 gears and has been proven to be extremely reliable.

The diff can be built with a narrow or wide 51t diff gear. This allows you to fully customize your race car for any condition. Whether, you run 17.5, 13.5 or the highly contested modified class. This Gear diff will have you covered and get you to the finish line every time.

Part 1

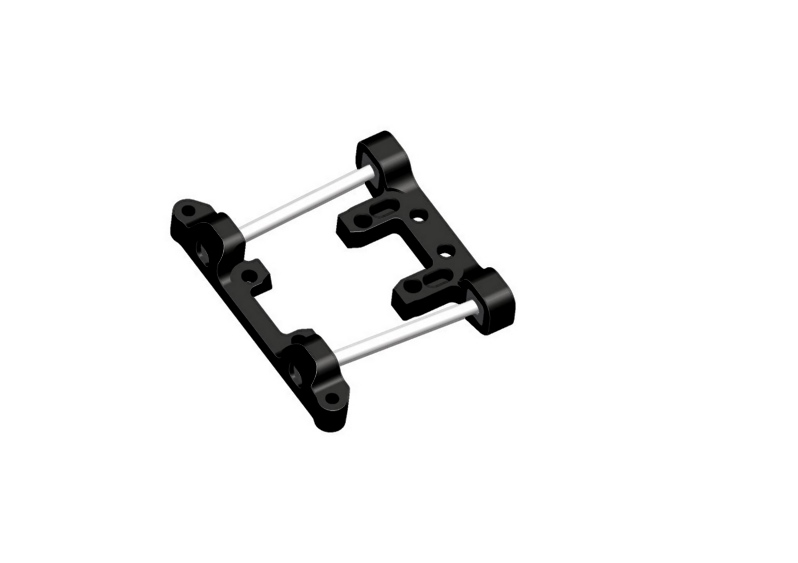

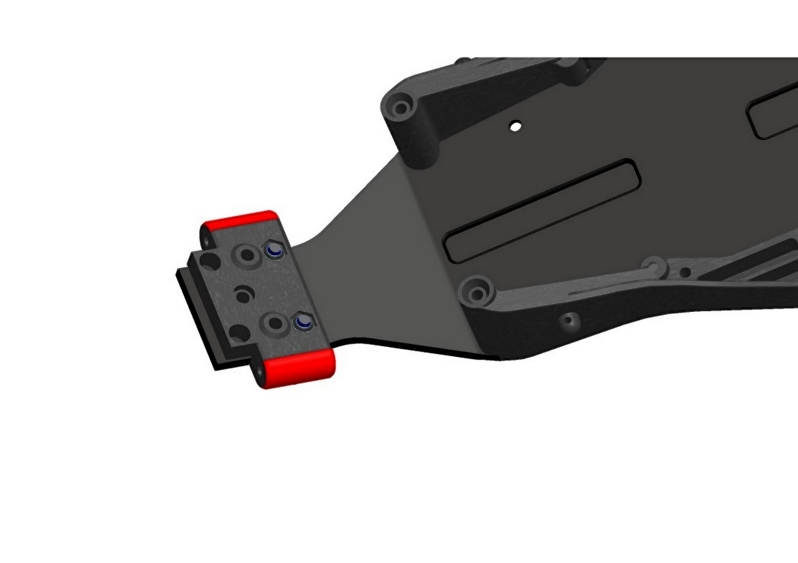

New Narrow Rear Pivots / Insert System:

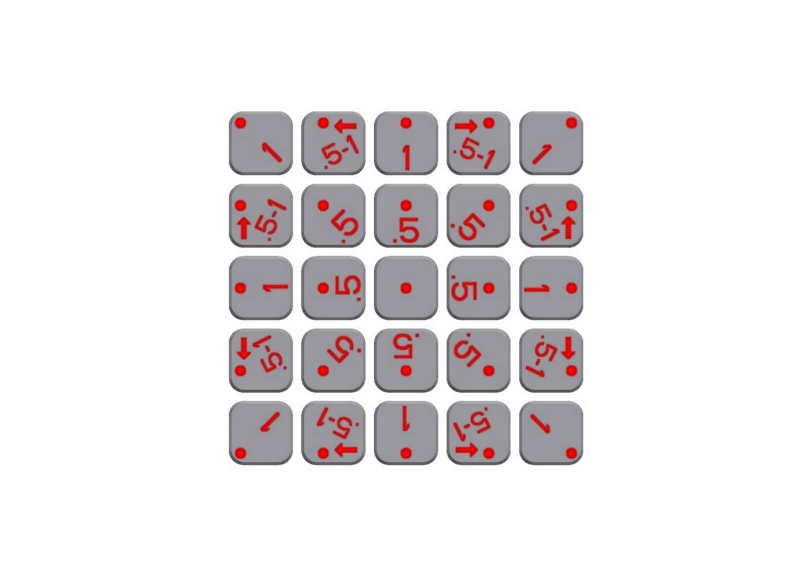

With the 2wd market becoming more refined every day, we felt it was only natural we jump on board and ride the train. With narrow pivots becoming more and more of a factor in performance, we actually brought back the Narrow rear pivot from our RM car. The pivot from the RM was 2mm narrower per side than that of its MM brother. Aside from the Narrow pivots, you will also be able to purchase, medium and wide pivot sets for even more adjustability as optional parts. When we made that plunge to make new pivots, we also stepped away from our old insert system, and adopted a completely new one.

The old system was only adjustable for 1 degree total toe, 0.5 in or out. The new system will allow us to go 2 degrees total, 1 degree in or out on each pivot block. This same system is also adjustable 0.5 to 1 degree in almost any direction. We didn’t cheap out like many other makers, we actually made a complete set of inserts. This will help increase the adjustability in a much larger variety of conditions. We want to see this car excel in every condition, anytime, anywhere. In order to do that, you need to have all the tools to do so at your disposal. Oh, and I almost forgot to tell you how amazing they look anodized jet black with silver chamfered edges!!!!

Part 2

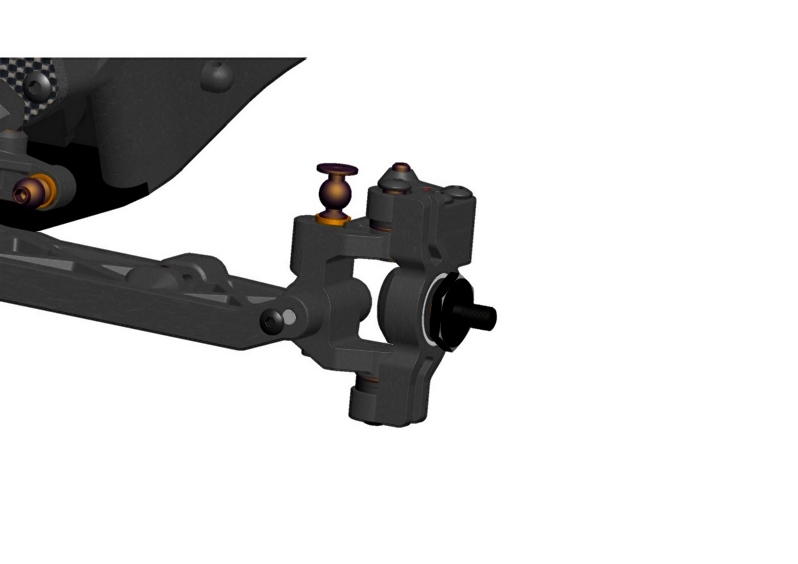

Fully adjustable new upright:

All New Track width, axle position, and Roll center adjustments.

A: The new rear uprights are part of our movement to make the most versatile buggy on the planet. With so many new features on this upright it will literally make your head spin off. You can adjust the roll center by way of 7 different positions in reference to the distance away from the axle. Those steps are 0.5mm different. You can then take the same inserts and adjust the offset of the upright by way of 1mm.

B: The upper camber link has an adjustable length, which is done by way of shims between the camber link mount and upright. The camber link mount is flappable so that there is a perfect overlap so that no length of link is missed.

C: The vertically mounted ball stud further enhances the setup, so you can adjust the Roll center in the absolute finest amount to perfect the setup.

D: The wheel axle can be adjusted in 1 and 2mm increments in or out. This will allow you to adjust the driveshaft length, but also the location of the outer driveshaft pivoting point. This adjustment has an influence on rear end grip and lean. We offer the original 65, 66 mm drive shafts as well as two new ones, 67mm and also 68mm.

If you haven’t figured this out by now, we mean serious business. There is no doubt, winning is the first thing on our minds.

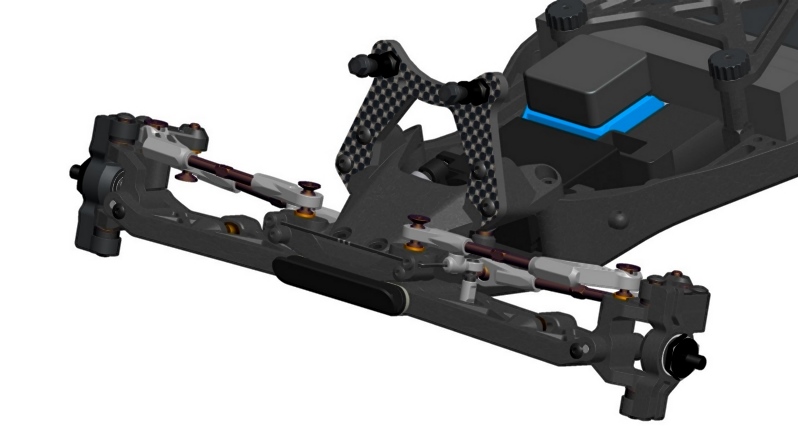

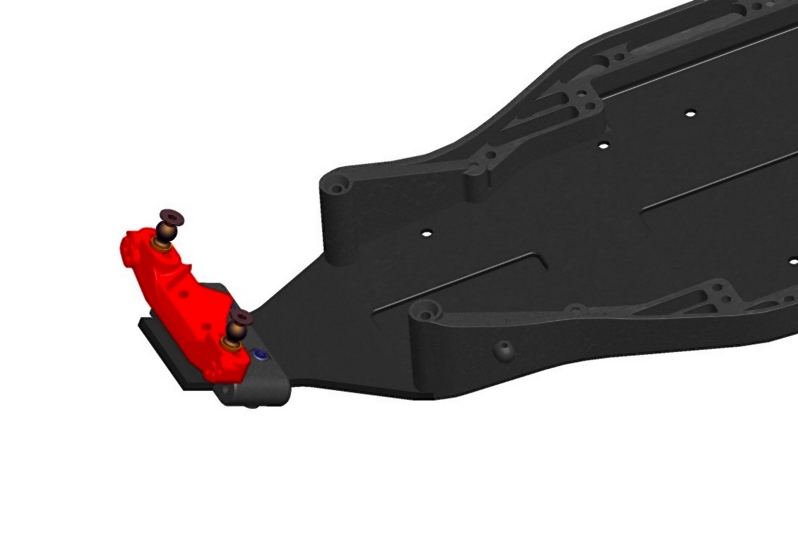

All new rear shock geometry utilizing the shocks mounted to the front side of the arm.

When we developed our first Mid-motor 2wd, Mid-motors were still in their infancy. The learning curve was steep for everyone. We also had a lot to learn in regards to what makes one of these cars really tick. As time passed, moving the rear shocks to the front side of the suspension arm, proved beneficial in cornering, jumping as well as sheer speed. With that in mind, we went back, updated the height of the tower to maximize the down travel as well as up travel. We tested multiple towers and angles for maximum grip, cornering and stability. The end product was an easier to drive, yet significantly faster car. We are very proud of what we achieved here as the performance was a huge step forward over our previous Mid-motor versions. The first time you hit the track with this car, you will feel the lateral grip it generates. This is the same kind of grip, which gives confidence to overtake your competition in the toughest corners and tightest windows.

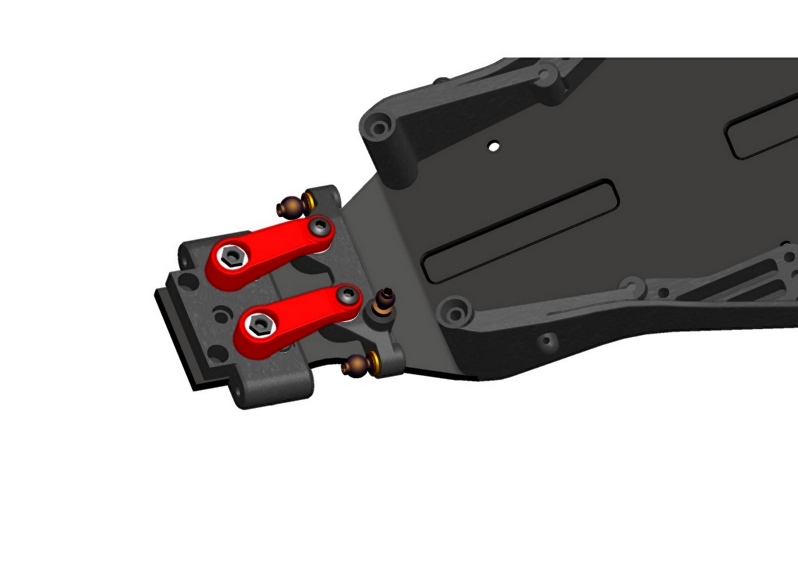

A while back we introduced a new low friction material to our SRX-2 MH; well we went one step further. Not only did we find an even better material, but we re-designed the balljoints and ballstuds so you could use a 2mm hex driver to install them. Aside from being able to install them, we captured them….

Class leading right there baby. So many times people lose their ballcups, sadly at the most in opportune time, while you’re leading or fighting for bragging rights with your best friend. Well, we were tired of seeing it, and/or experiencing it and wanted you to win all those races you had unjustly lost. A revolution has come, and these balljoints and ballstuds will be at the forefront. I have to say… You are welcome……

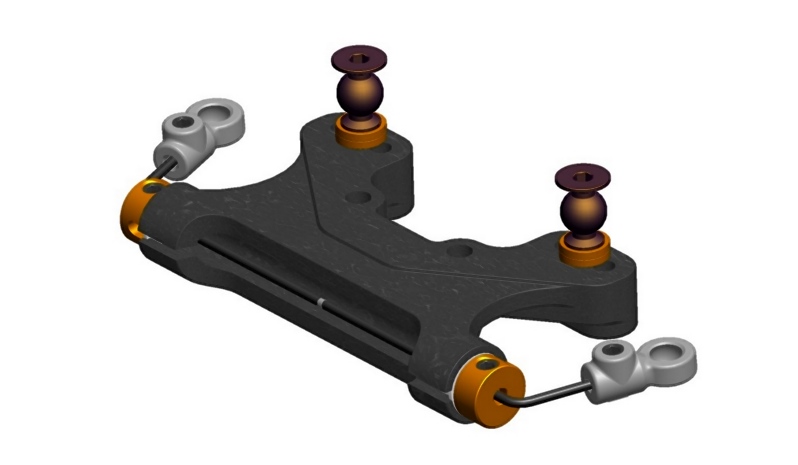

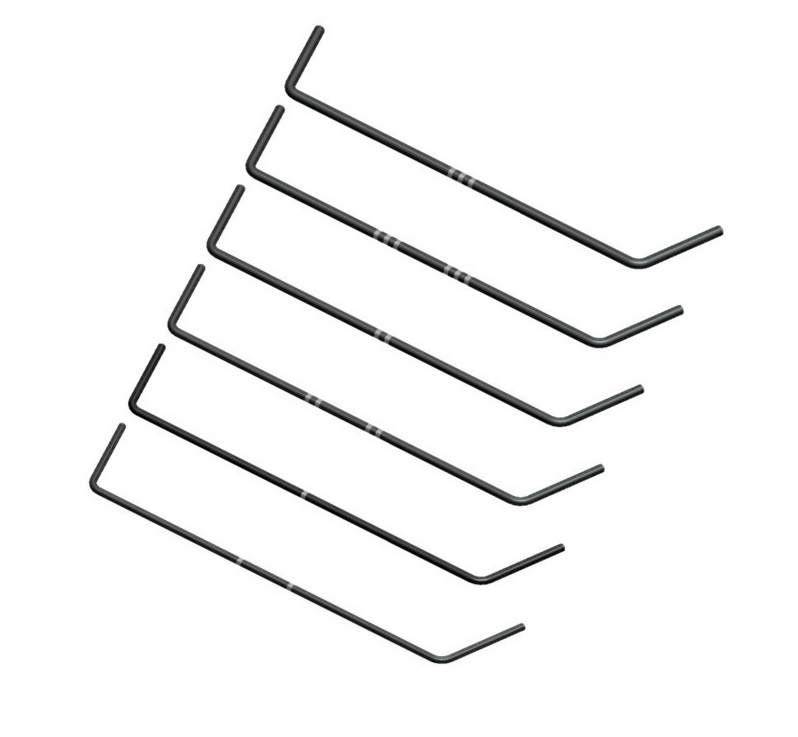

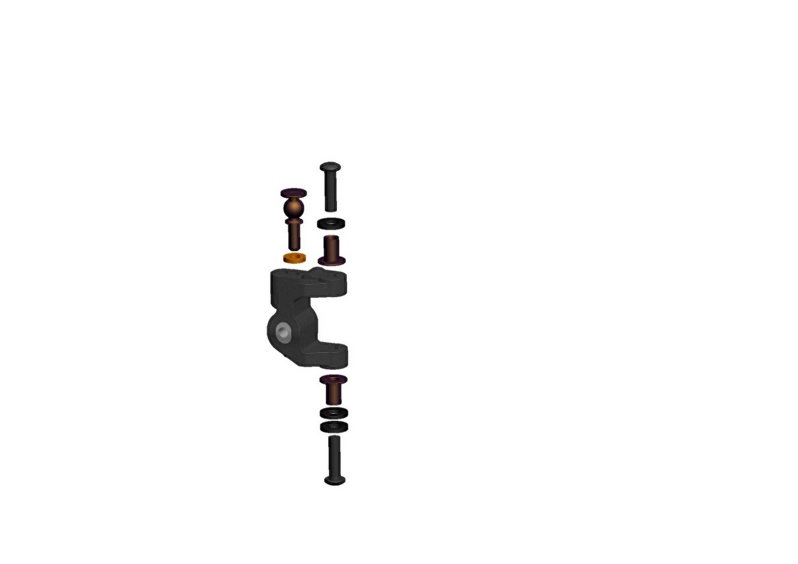

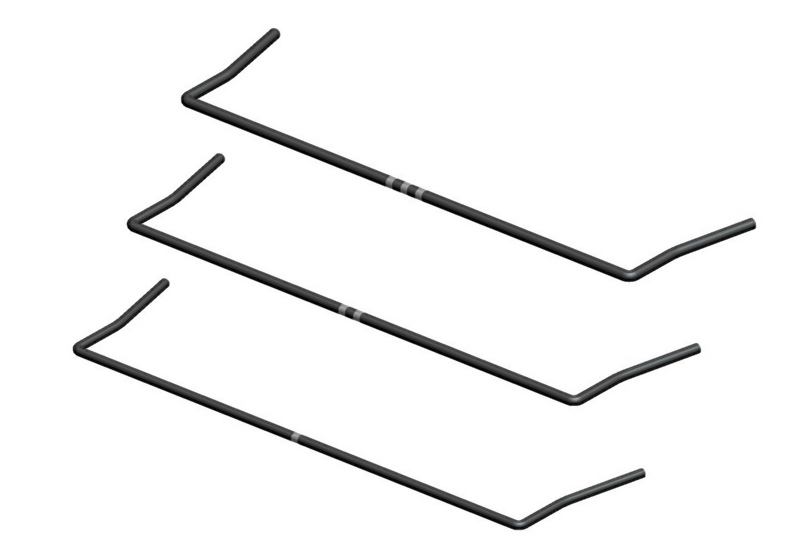

No carpet car would be complete without a ball bearing raced rear Anti-Roll Bar. This fully integrated sway bar system is super easy to install and remove with only two button head screws. In the event you want to use a standard rear camber link mount, you can swap it out super easy. If you love your sway bars, then you will be excited to know you have a large variety of rear roll bars to choose from.

We have 1.0, 1.1, 1.2, 1.3, 1.4 and 1.5mm roll bars to choose from. No matter the track conditions, you will be more than able to dial in that rear suspension.

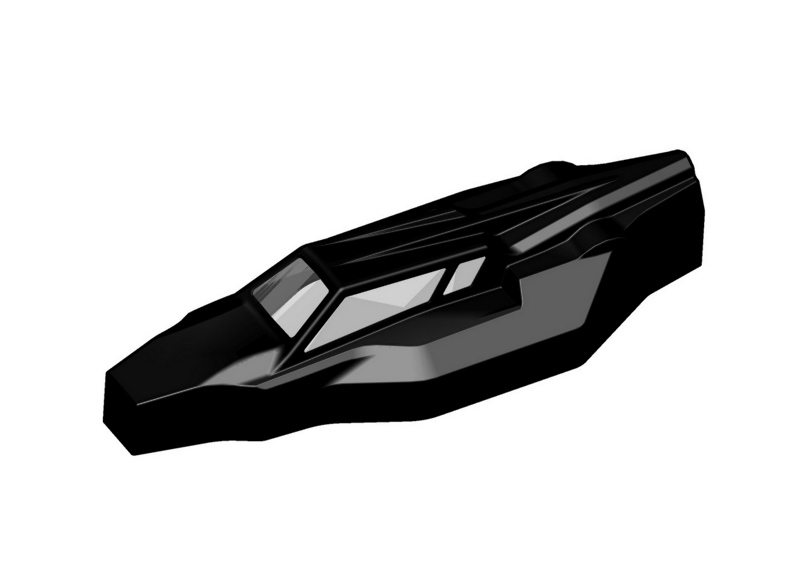

When it comes to RC racing, one thing that has to look good is the body. With that in mind, we gathered together many opinions to decide on what the new body would and should look like. Using some features from our original MH body which had been deemed cool, we elaborated on that. The idea was to make it more sleek, stylish and above all more tactical looking. The end product was a body, that was a step forward over our previous predecessors, and one that we felt would undoubtedly be accepted in the market as a great looking body.

Here at Serpent we are very proud to introduce the brand new…..

Serpent SRX-2….Gen 3

Designed by Billy Easton, USA

Team Serpent

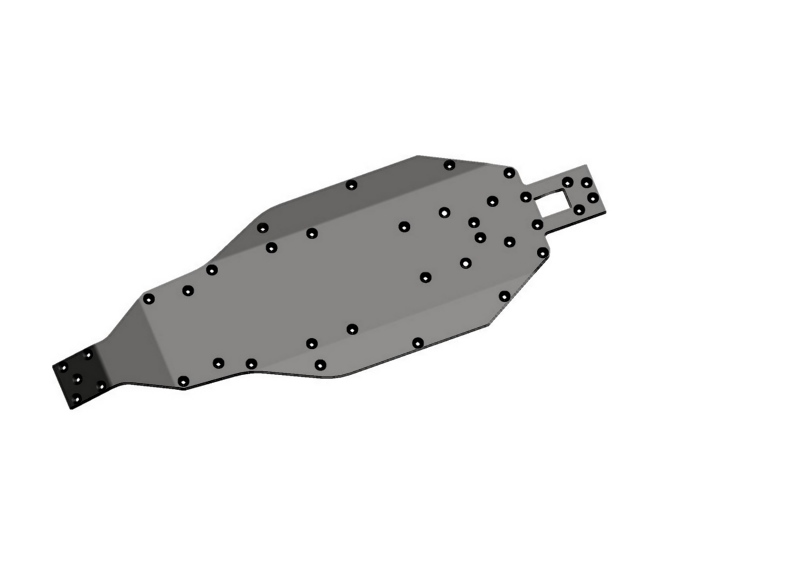

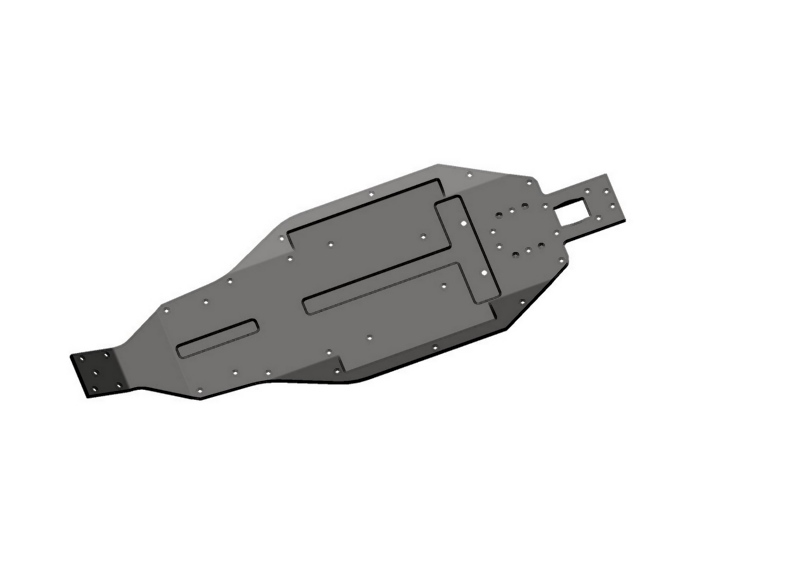

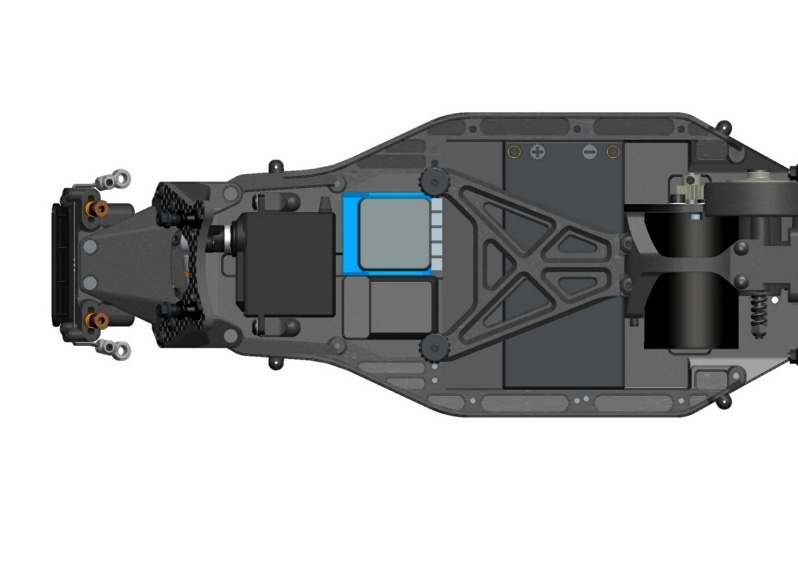

The foundation or in this case the chassis, is always the driving force in what sort of performance you can extract from your race car. With the interest of stiffening the front to back flex of the chassis, mostly in the center, we opted for a chassis with bent sides over our previous flat chassis. The life of the vehicle as well as how flat the chassis will stay over long periods of time is greatly enhanced. We also took our original front end design, accepted its weakness, and then pushed the envelope even further by developing a multi bend chassis.

With no other reason than to dominate every surface, we created an optional chassis with adjustable weight plates. The rear 14 gram weights will also fit the standard chassis; however this new optional chassis has an additional 4 choices when it comes to positioning weight. The Servo weight comes in an 8 gram aluminum weight as well as a 24 gram brass weight. The electronics weight comes in a 15 gram aluminum weight as well as a 45 gram brass weight. Whether you race dirt, carpet or astro turf you can full adjust your weight distribution and push your setup to the master level.

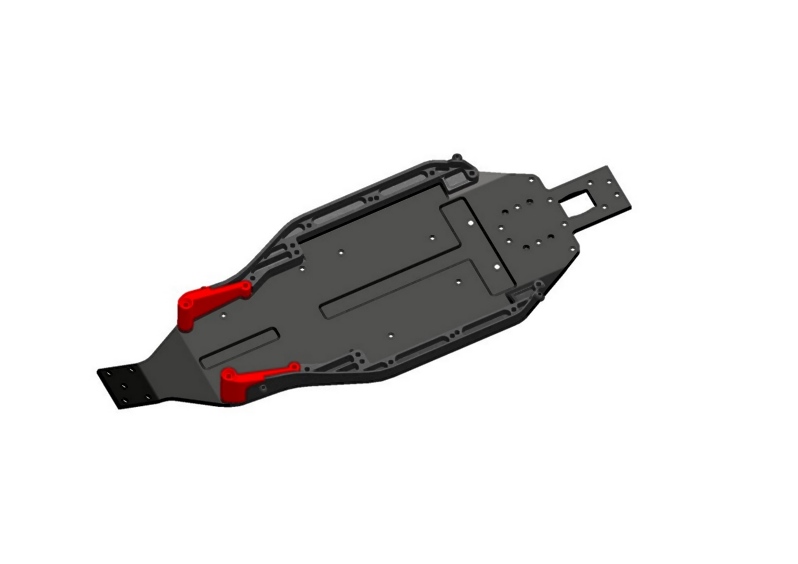

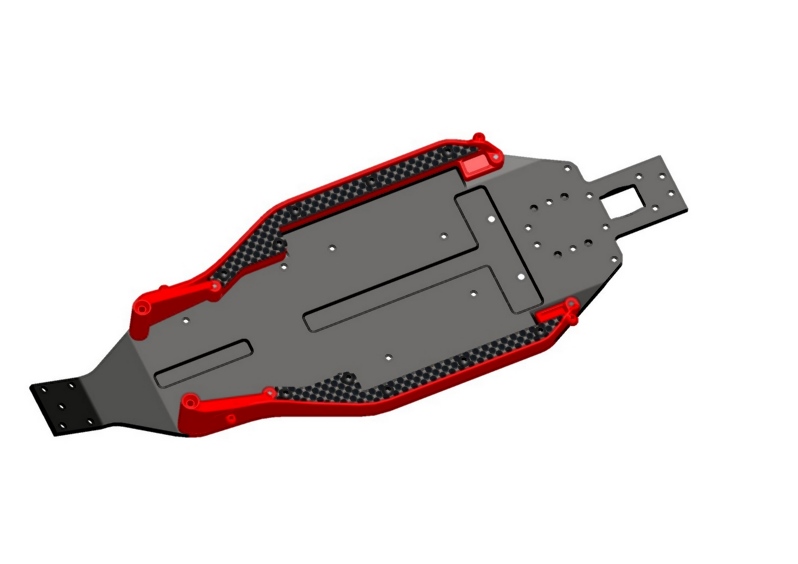

The side pods have been completely re-designed, in which it differs from the way we have done it in the past. The side pod itself is now separate from the front upper deck supports. This will allow us to make optional aluminum supports in the future, changing the flex characteristics of the front end.

Also on the front supports we added the body mounts, and then coupled that with the rear mounts, no matter who mounts your body for you, it will always sit flat, front to rear and be properly positioned. Whether you use the body clips or not, the pegs can be used to ensure that the body will always have proper alignment. Aside from the above mentioned design changes, the overall cars width has been reduced. This reduction in width enhances flight/articulation over jumps as well as reduces chassis roll.

Based on our customer feedback for a car that can do it all in any condition. One area that needed to be adjustable was the flex in the chassis. We came up with a super stylish, yet ridiculously functional way to achieve this goal. Besides who doesn’t love the stunning appearance of a great looking weave, of course we are talking about carbon fiber here. The small panels are 2mm thick and bolt directly onto the side pods. If you’re a fan of a super stiff chassis, we are certain this will satisfy your needs. These side panels will be sold separately and can be found in our “Optional” section on the web site.

The previous SRX line of cars, there were some good things, so we kept those, namely mounting the lower bulkhead to the kick plate. This is simply the strongest way to do business and it also keeps it in place while doing any maintenance on the rest of the front end. We also increased the boss diameter for the inner hinge pin by 1mm. This will add more overall strength for frontal impacts when you are trying to move the car ahead, which has held you up for the last 3 minutes while you continue to lead the race. You can rest easy knowing how durable your new car is and drive it like a real animal. Unleash the real beast within you.

In addition to the strength upgrades, we separated the front upper camber link mount from the lower and upper bulkheads. This allows the user to replace the parts independently if they strip out a camber link mounting hole and or the shock tower mounting holes. This also allows us to make an optional aluminum camber link mount in the future for weight distribution, alternate geometry and or to add more strength.

The original SRX-2 steering was good at delivering your input at the radio to the wheels on the ground, with a no fuss, no feedback scenario. However, one issue it had was the steering bell crank arms were just too flexible. Well, we strengthened them. The good thing about this improvement is we took something good and made it great. Aside from that, we added one more Ackerman option, a “0 “, which will give you an even more smooth feel than the previous #1.

This will now give you a full range, 0,1,2,3 on Ackerman side of things. There is nothing more comforting than knowing you have the most precise and tuned weapon on the battle field. This updated steering system, will not let you down when you are in the fiercest battle for a coveted win.

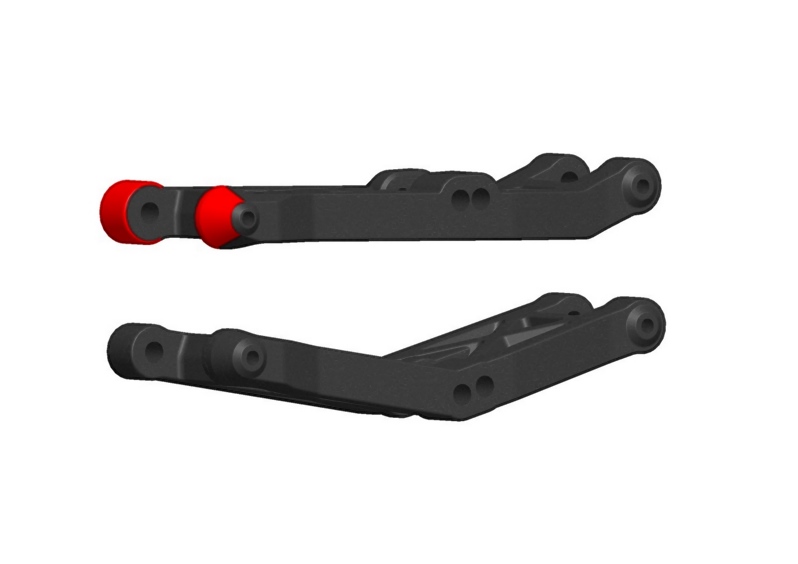

Gull wing, straight arm, the debate will live on forever. However, now we offer both. There were many instances where the gull wing arm, offered handling advantages and the same could be said for straight arm. The customers talked, and we heard you loud and clear.

Not only did we make a new straight front arm, but we beefed up the inner boss around the hinge pin to increase the strength to ensure you finish every race you start.

n order for Serpent to progress, we had to accept the old front end geometry was more suited for a Rear Motor. So what did we do…. We tested until we were completely confident we had something that could propel us into the distant future. The end product was a new roll center. It also is a more adjustable and more durable front Caster block/Steering block assembly.

You can now adjust the front roll center 3mm instead of the previous 1.5mm. We also increased the material around the bearings. We didn’t stop there though as we removed the outer 5x10x4 bearing and replaced it with a super long life 5x13x4. We added a vertical mounted ball stud for fine tuning the camber link/roll center.

We changed the axle design so you can use a spacer between the axle and outer bearing. Other than giving more adjustability to the track width, you can now use any wheel on the market and be rest assured you can adhere to any rules and have highest performing scrub offset. Our new front is nothing shy of being a huge step forward. Progression is the name of the game, and that’s something we are no stranger’s too.

A New addition to the SRX-2 Gen3 Carpet car is an all new front Anti-Roll bar/Camber link mount. We wanted to maximize durability, increase the support on the sway bar, and make removal and installation a breeze. The new mount can be swapped out for a standard version if no sway bar is needed in under a minute’s time.

The ARB mount is super strong, and accepts various size sway bars from 0.9, 1.0, and 1.1mm sizes. No matter what grip of Astroturf and Carpet you may encounter, the versatility will give you all the tools you need to succeed.

We know what it means to be able to work on your car, and to do it at break neck speeds. On our previous model, you had to completely remove the upper bulkhead to work on the bell crank and or remove the drag link. Well, we learned our lesson and jumped back into the meat grinder. We increased the area around the servo for wiring and also the ability to move the servo front to back. We coupled those improvements with easy access to the bellcrank and the drag link, by way of a new upper bulkhead/top deck. You can get the servo in and out in a matter of seconds, whether you want to adjust the horn, or replace your servo.

Increased room for Speed control and receiver:

No matter the speed control and receiver you use, we have increased the area to the front and back as well as sides. This gives the end user, more freedom to position his electronics in the most optimal positions.

Increased battery compartment and adjustability:

The battery compartment has been expanded to fit a Block Battery or even Saddle packs if you wish to. If you do not want to use either of those batteries, you can use a shorty and move it a smashing 23mm for some serious adjustment no matter what condition you race in.

Let’s take a look at the features shall we..?

1) The differential is accessible by 4 vertical screws and 2 horizontal screws and you will need to remove at least one shock nut. The greatest part of the removal process is not to worry about the camber link mount dangling, rear suspension or having to take off the wing. The removal of any un-necessary parts has been completely avoided.

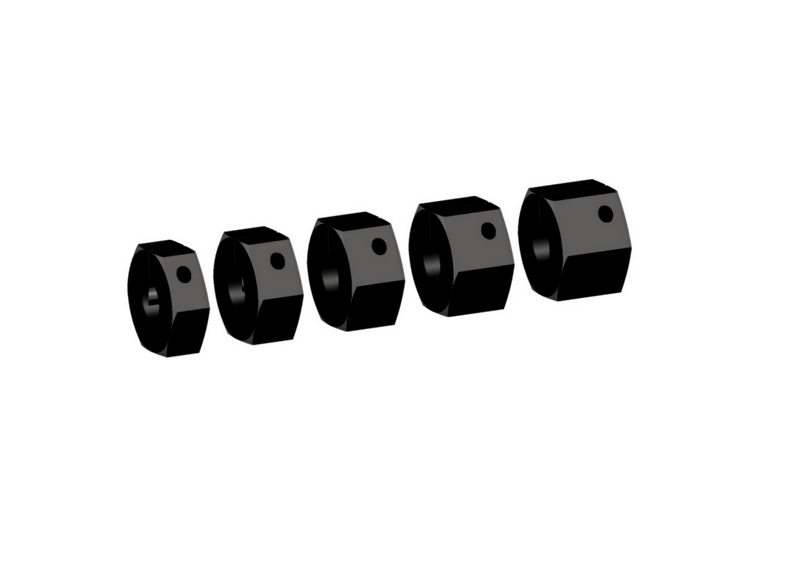

2) The differential height can be adjusted in 5 different heights. The inserts are now blocked into position to make sure that the oval inserts can’t rotate slightly during operation causing damage to the internal gears. Sadly our competitors copied our previous design of the oval insert but didn’t realize what we had already learned. Shame on you…

3) All drive gears have had the width increased to 10.5mm. With the increase in gear width, you can run on any surface and be rest assured you will not strip a gear. In addition to widening the standard gears, we will also over Stock racing gears that have been manufactured to 6mm wide. This reduced width will give you massive gains in rotating mass as well as reduced friction and power train loss. If i must say it, yes we are here to win and prepared to keep it that way.

4) If you have the differential out for maintenance, change the diff height or swap over to the stock racing gears, the idler gear can be removed by a single Button head screw. This allows you to do any necessary work inside the gear box with the least amount of assembly related issues. Nothing competes with brilliance.

5) To top off all the great things about this transmission it was only imperative to make the top shaft as easy to remove, and or replace. To remove the top shaft, simply remove the slipper, and 3 motor plate screws and boom, it’s in your hand.

6) New spur gear protective guard.

7) New Transmission brace with a single leg, for optimal rear end flex.

The Serpent brand as a whole is very dedicated to making a difference in the 2wd market. This new platform is our way of doing just that, by making a difference that drives the market forward, while providing class leading ideas and technology.