Description

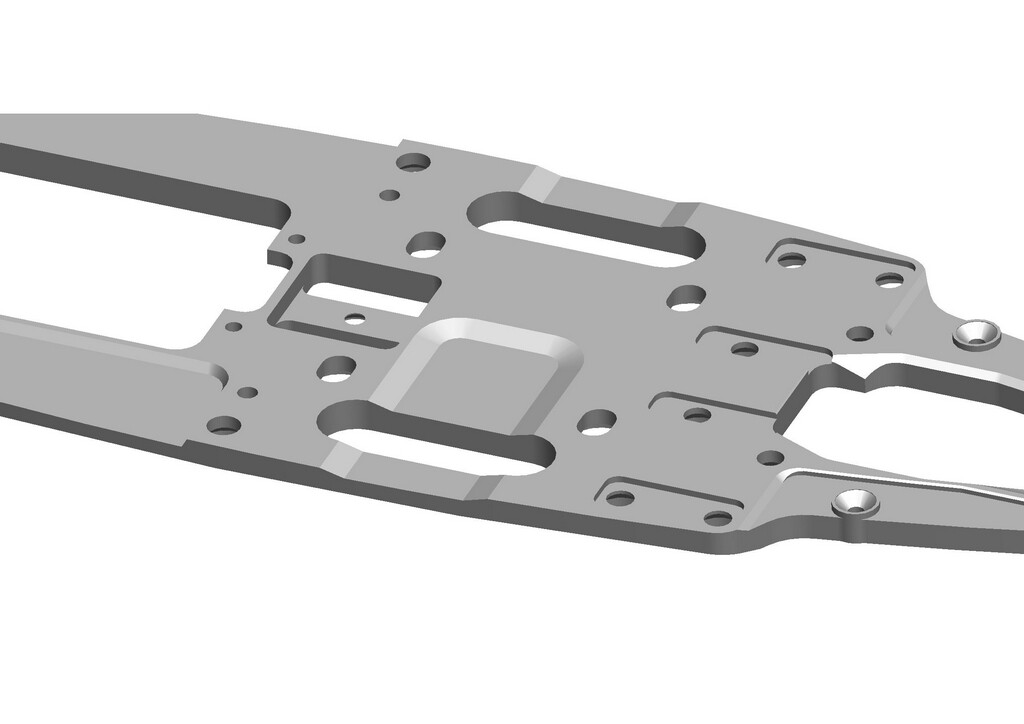

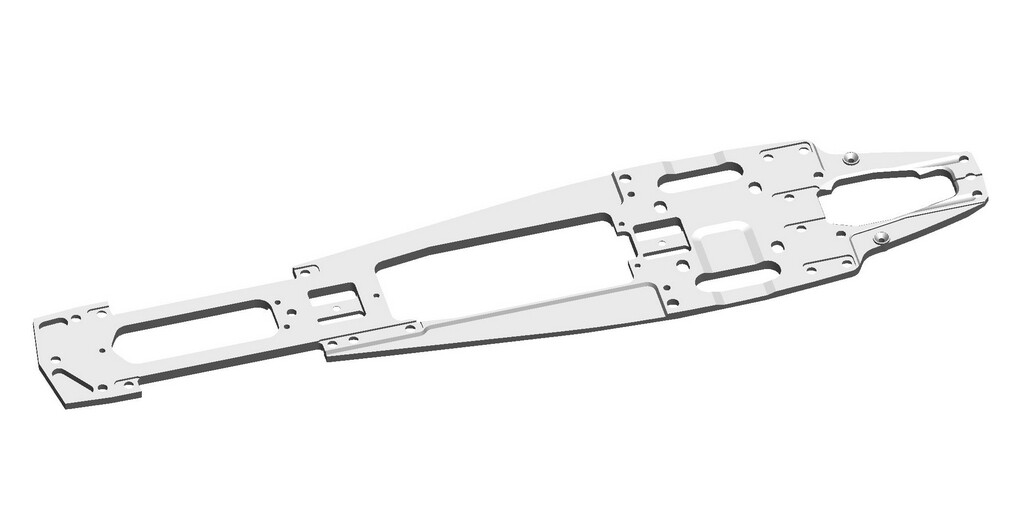

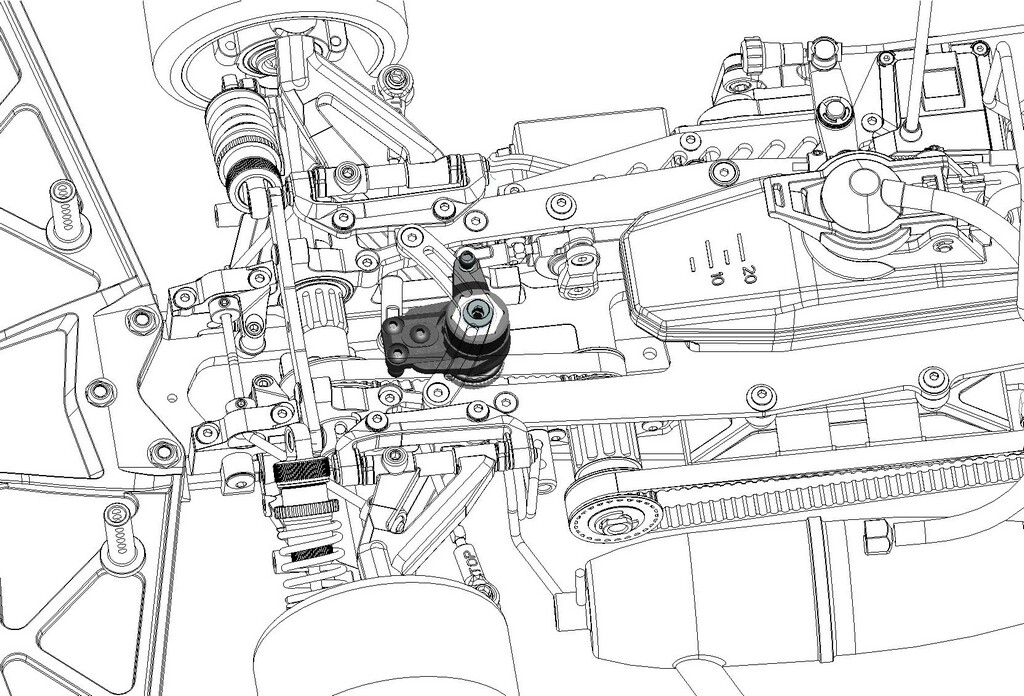

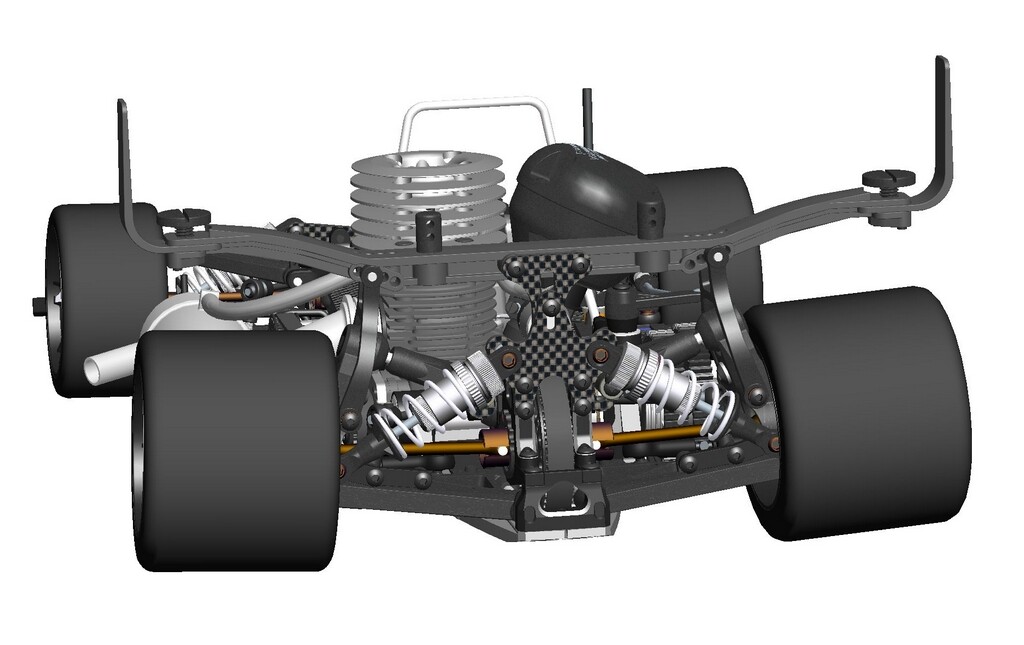

The ultra-narrow chassis is milled down to allow the lower radio plate as well as improved flex.

keeps the improved flex characteristics.

The central hole underneath the tank is narrower, as a consequence of the narrower chassis.

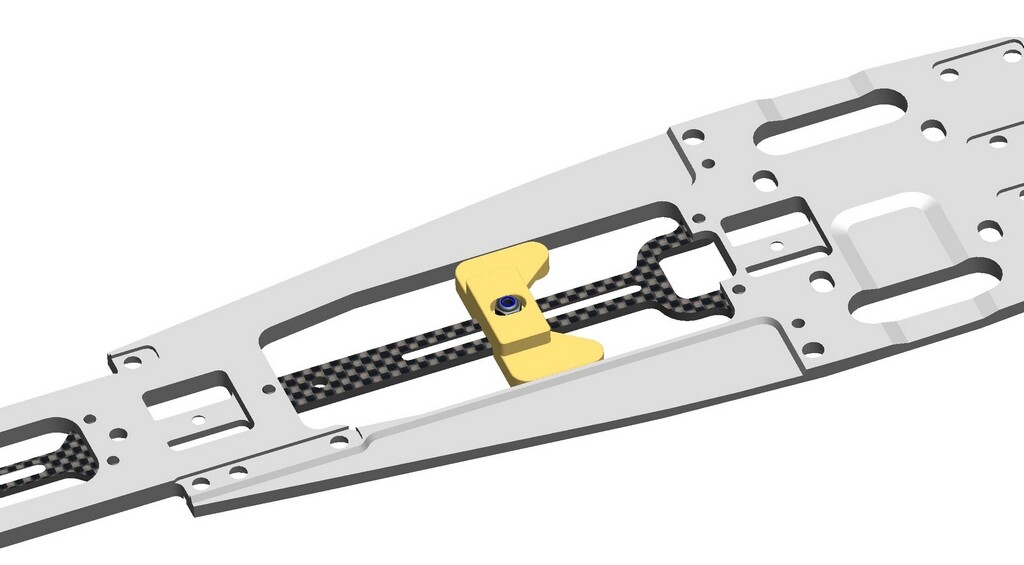

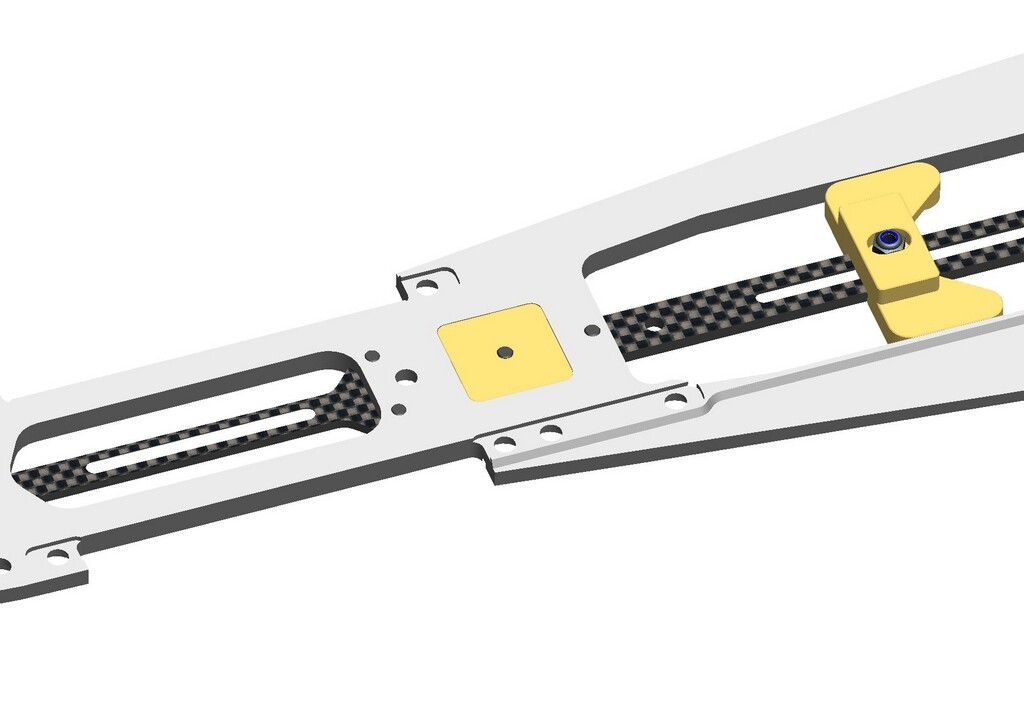

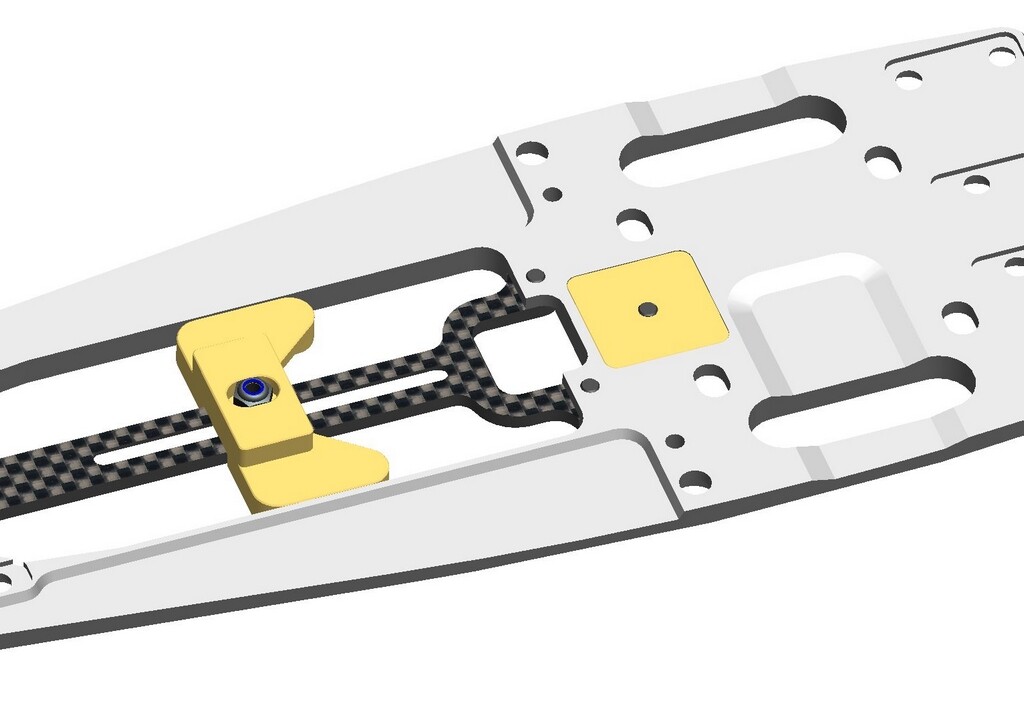

The central weight bridge is now mounted from underneath and allows for a quick change of the weight.

The weight itself is now fixed using a nylock nut. Bulletproof!

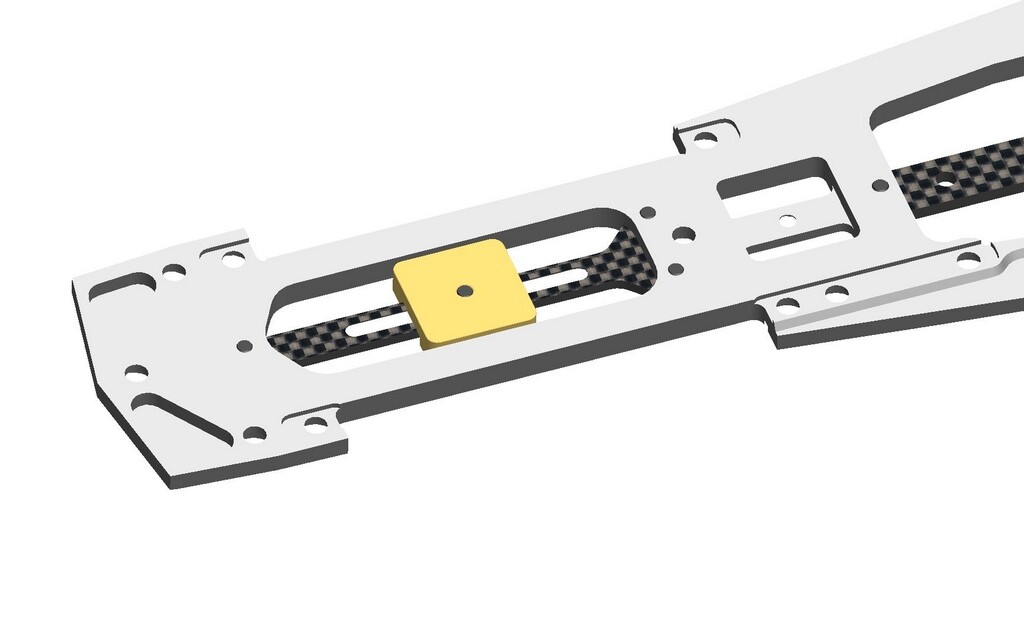

The front weight bridge is now also mounted from the bottom to allow easy access to the weight.

Also the front weight is now adjustable from the bottom.

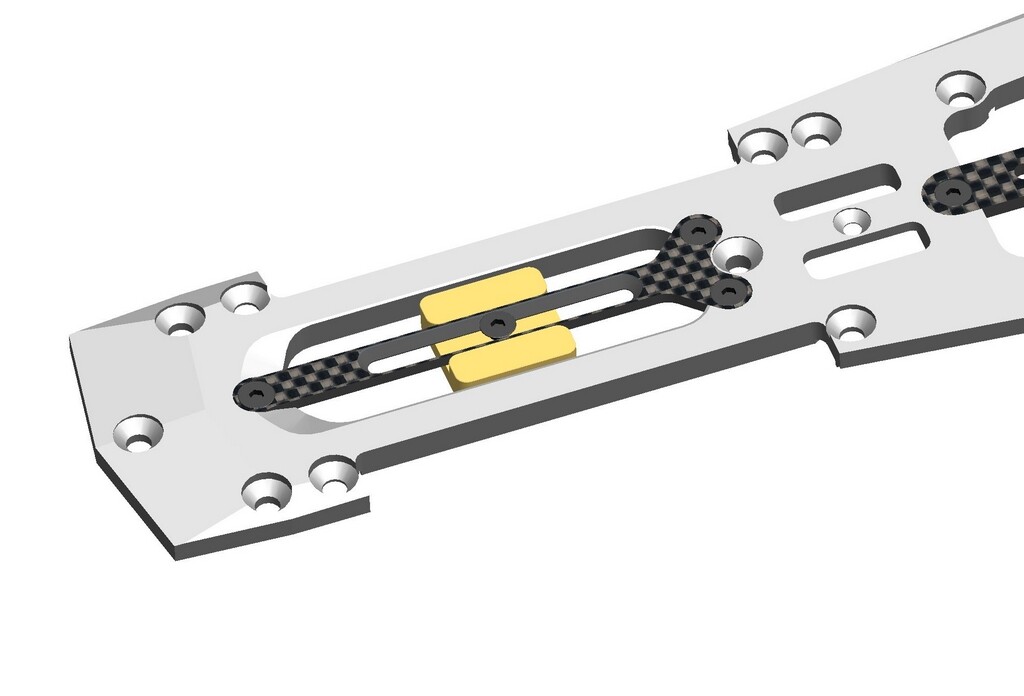

There are 2 additional locations to put a small weight, just behind the servo-saver.

And in front of the engine.

The engine has been lowered 1mm for improved flex as well to lower the CG

The rear of the chassis has a slot. This will be explained later here. It has to do with adjustable flex.

It also carries 2 steel countersunk screws that act as a counterpart of the down-stop screws.

This helps to keep the down-stop more accurate and consistent

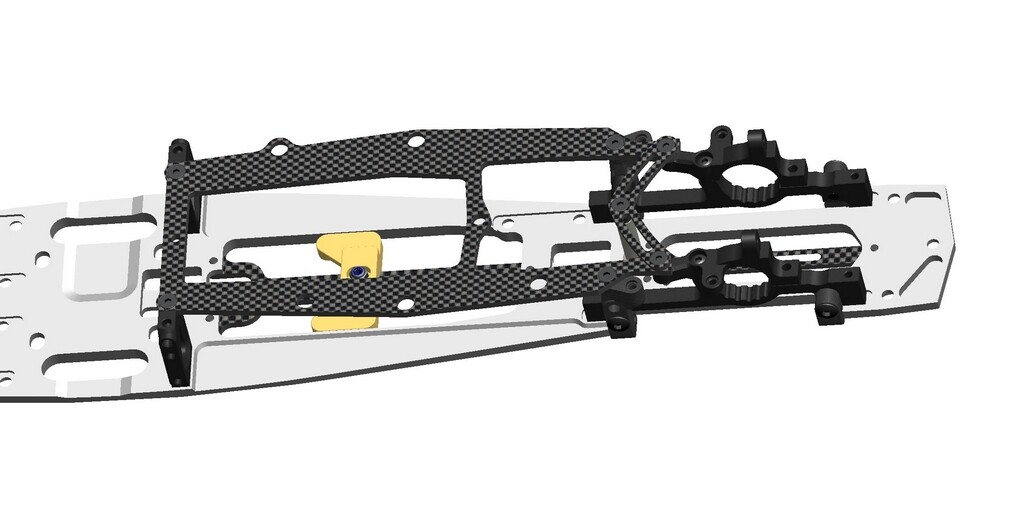

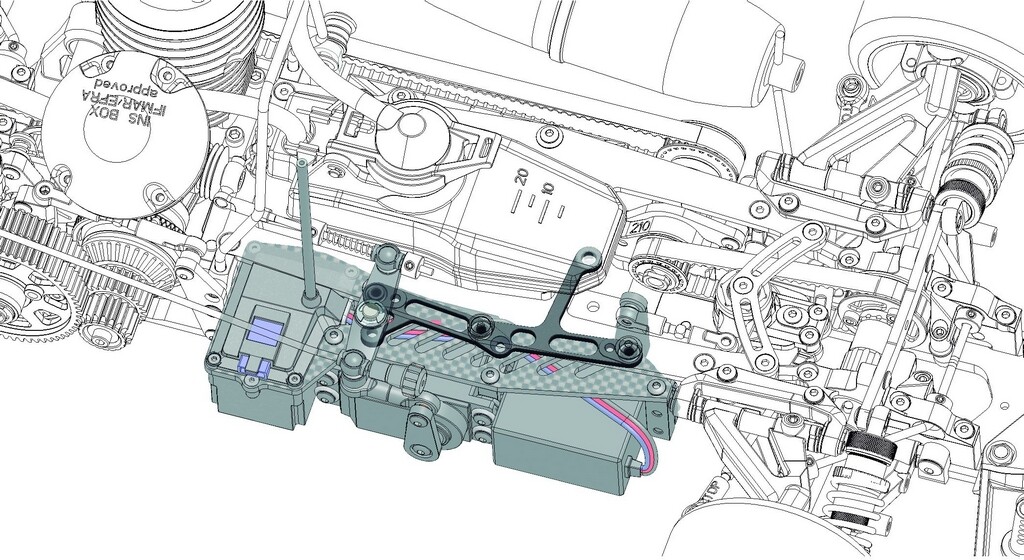

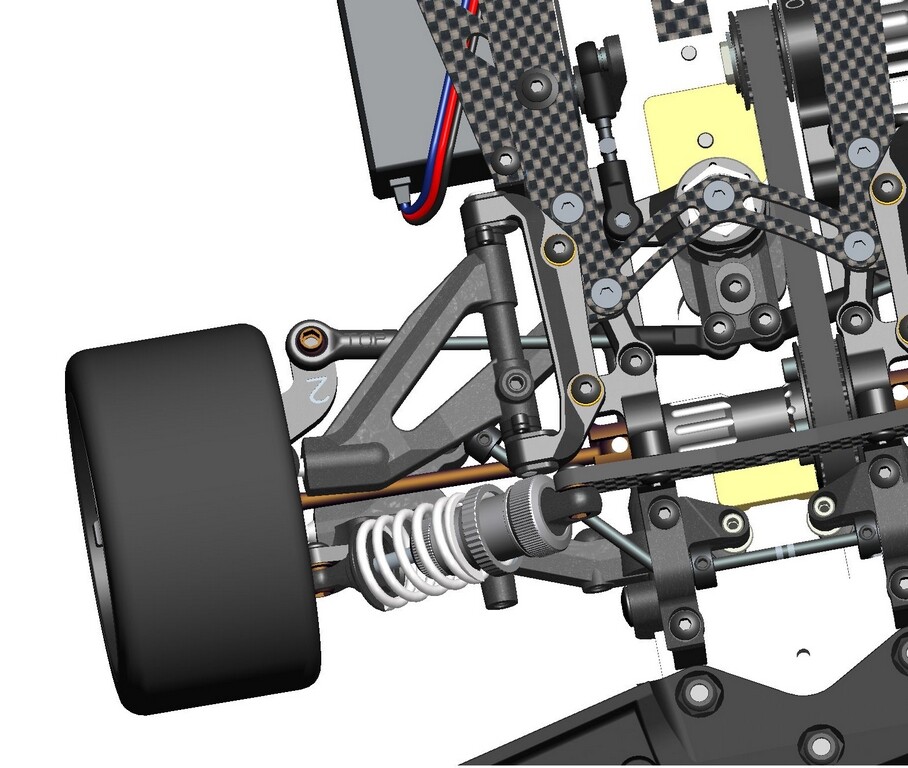

Talking about flex: we tested a lot and one of the improvements came from lowering the radio plate by 2.5mm. We also change the shape of it.

The front of the car can be adjusted to more flex by removing the front stiffener bracket

The rear of the car is also adjustable regarding the flex.

To regular rear end features the proven, one-piece rearplate

As an option it is also possible to use a softer rear end using a optional 2-piece rearplate

The radio-box is completely new. The “backbone” of it is a carbon plate and an aluminium frame.

The aluminium servo mounts are eccentric and can be mounted in 2 ways to adjust them to the brand of servos.

The receiver box is more spacious than the one used in our 988, still it is very compact.

This new box is mounted to the radio plate in a flexible way in order to not influence the flex of the car.

The extending arm of the frame helps to keep the radio box in the desired position without influencing flex.

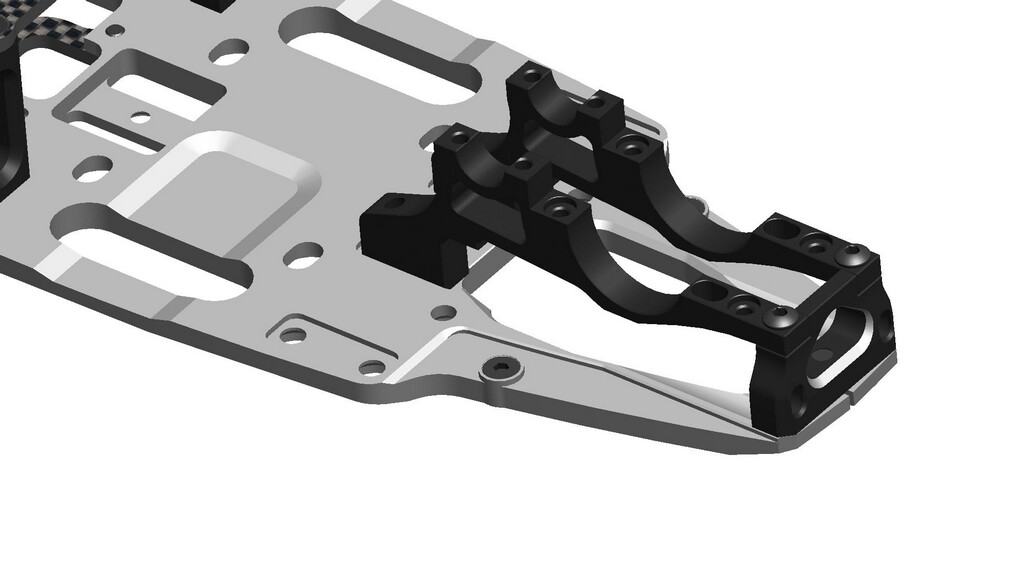

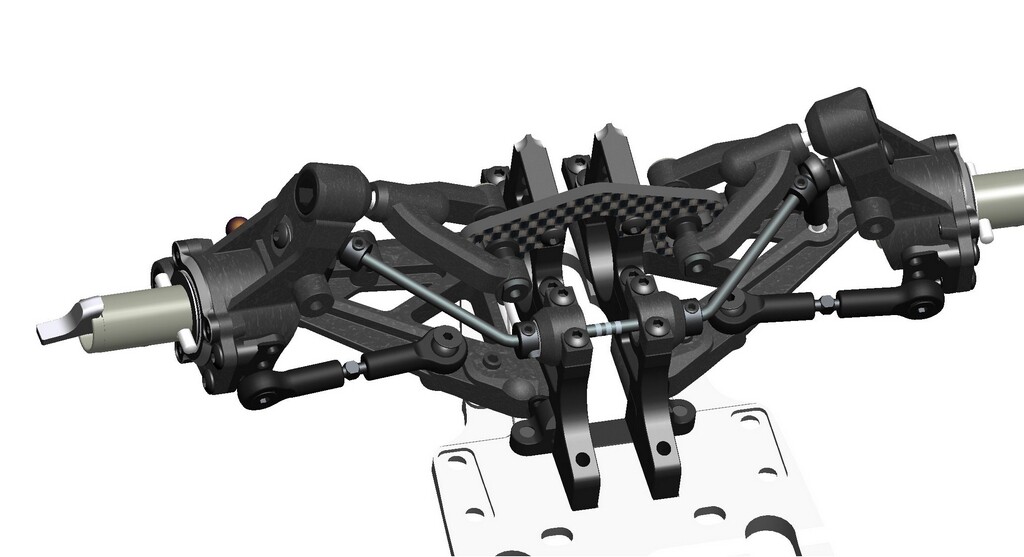

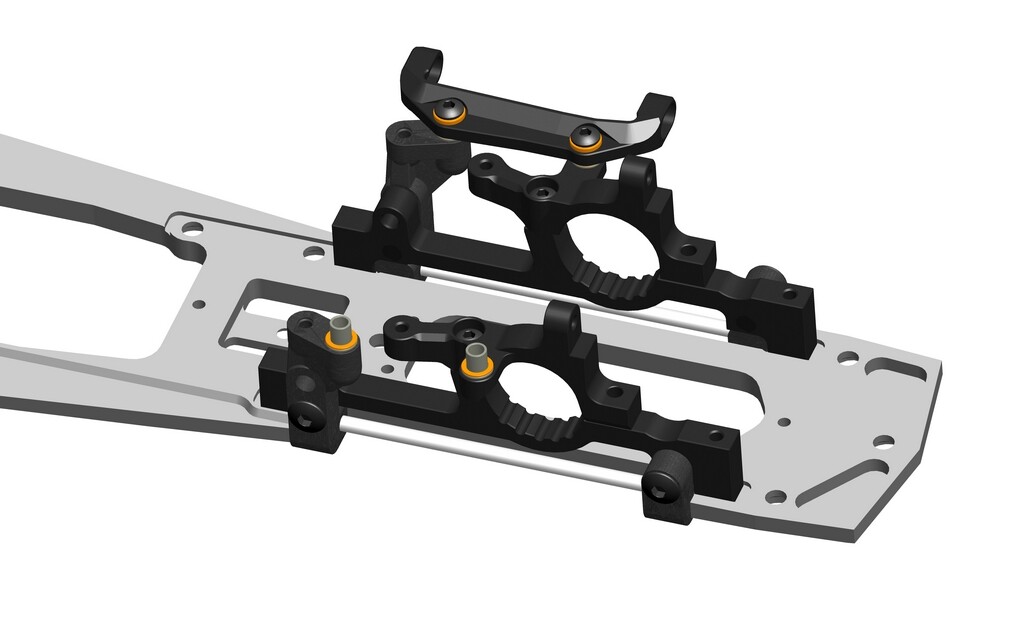

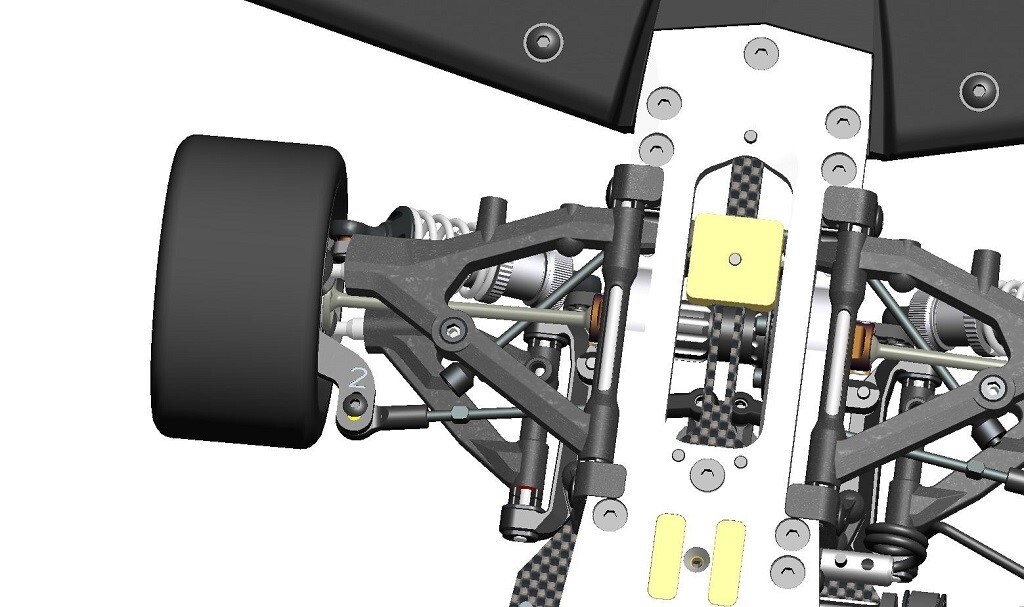

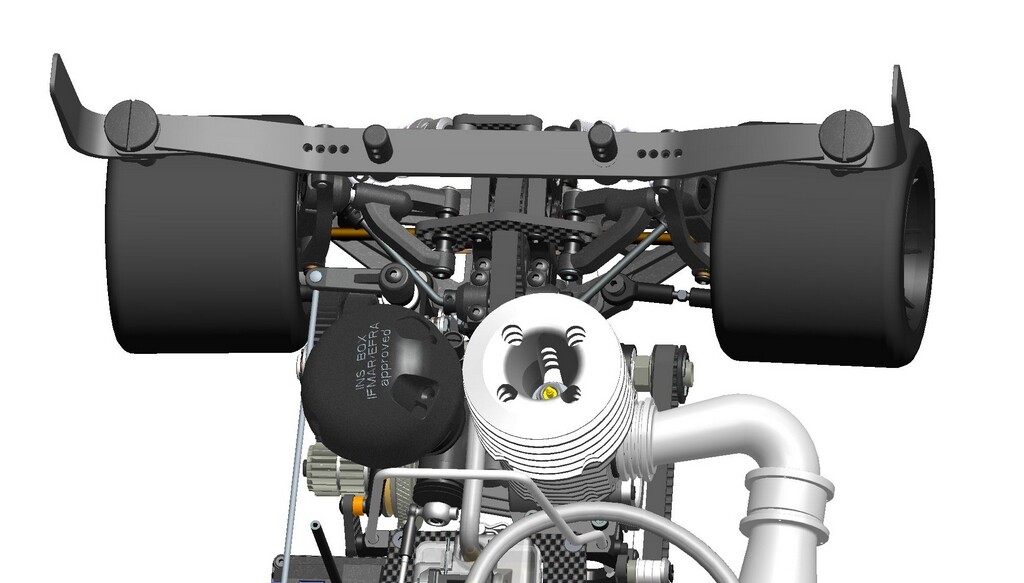

The rear end is completely new.

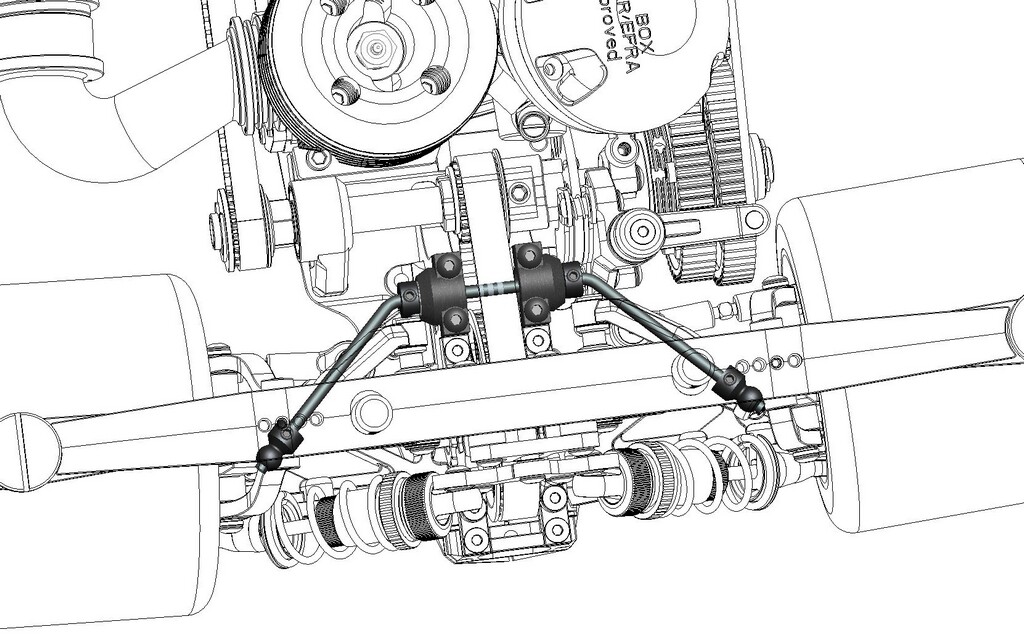

It features a new design to allow an re-active toe-change as well as avoid any binding at all!

By changing the position of the link the amount of toe-gain under compression can be adjusted.

The position shown is the “neutral” position.

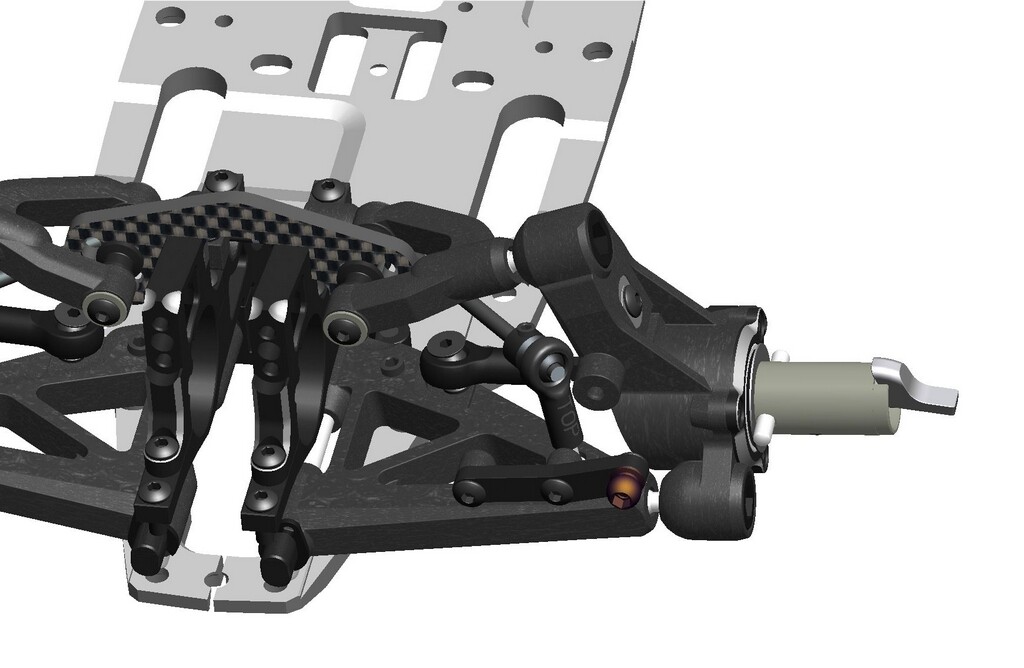

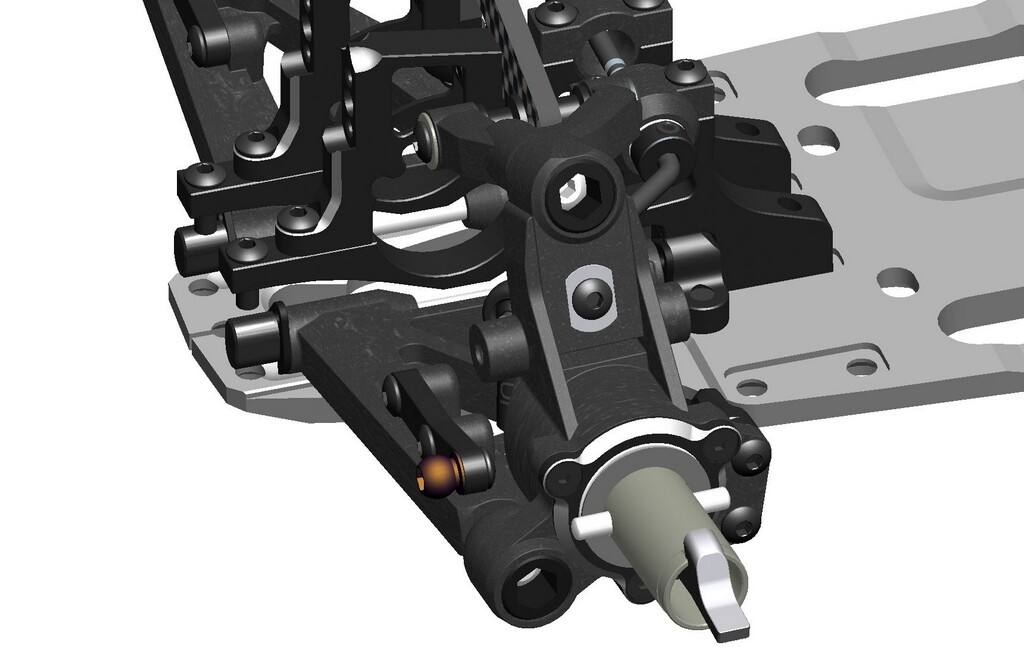

Since the upper link is replaced by a suspension arm, we also changed the upper pivot on the upright.

It is now super easy to adjust the correct camber.

The height of the pivot ball is adjustable by changing the aluminium insert.

There are 3 positions

The upright carries an aluminium insert where the ball bearings of the wheel axle sit.

In that way we can achieve the perfect roundness even under load to achieve the least friction of the transmission possible.

In this way it is also really easy to remove the wheel axle/driveshaft for maintenance

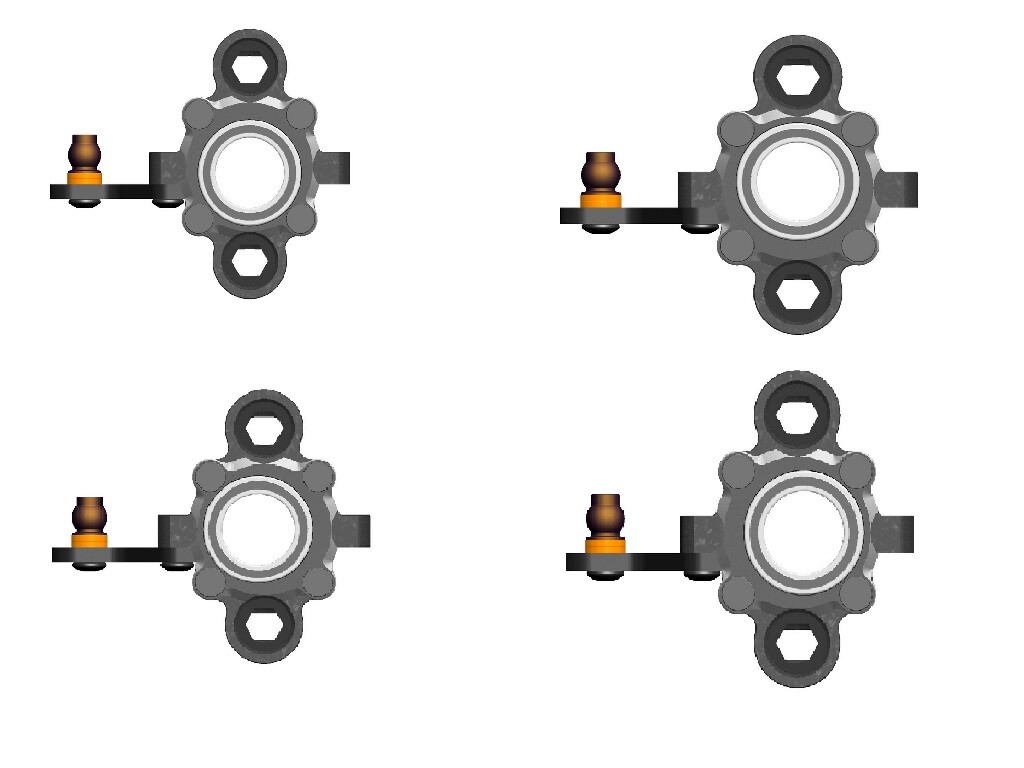

The front steering-block features a similar construction.

The aluminium insert gives the same advantages as in the rear with improved drivetrain effectivity and improved ease of maintenance

But because this insert is eccentric, it is also possible to change the roll-centre as well las using a trailing or leading set-up.

Of course the steering-blocks are still left/right symmetrical and can be used with option1 as well as option2 levers.

The front upper suspension bracket now has an improved design takes provides a better placement to avoid camber or caster irregularities by using bushings.

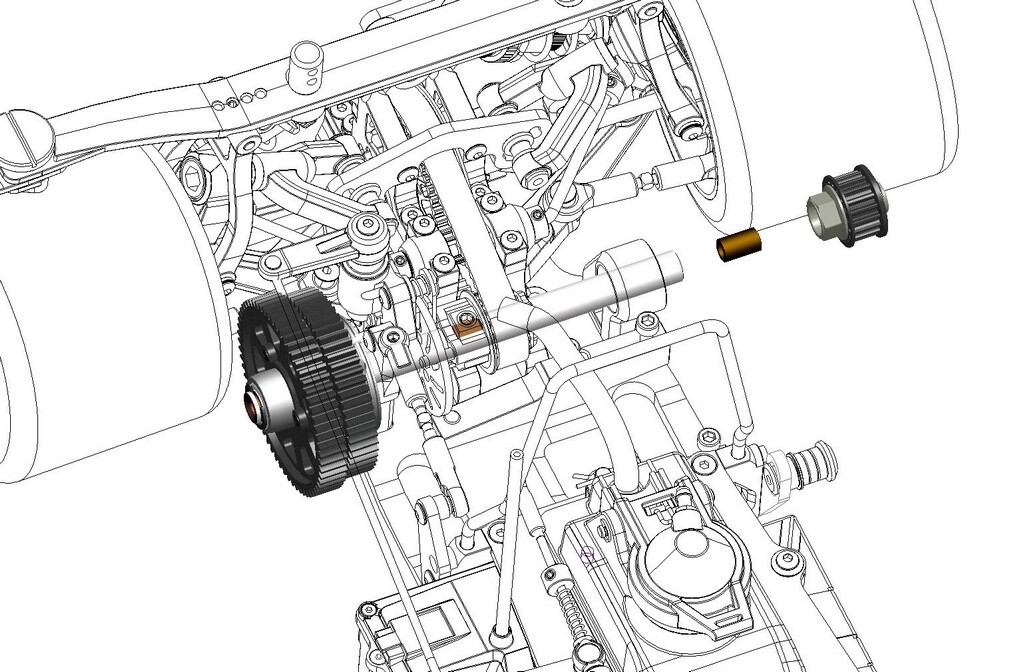

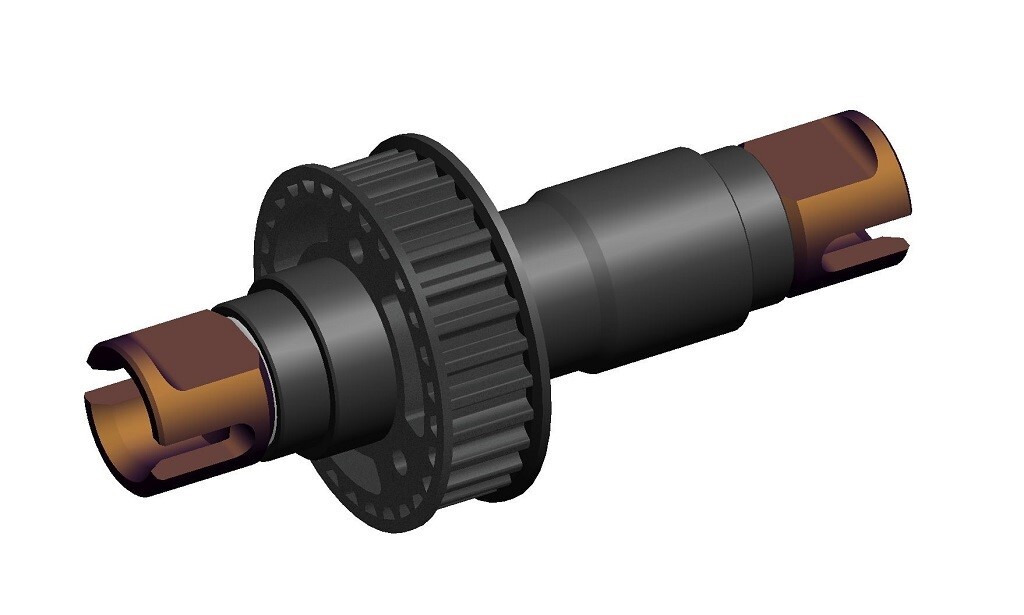

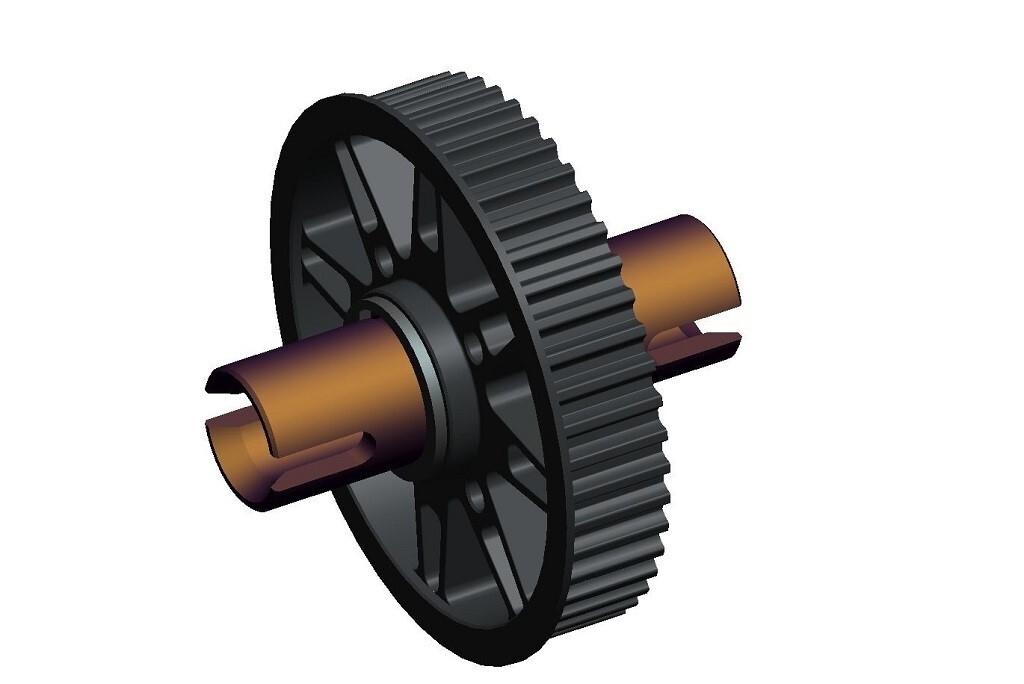

The new lighter 2-speed shaft is 10g (!) lighter and features a super-true mounting of the 18t pulley adapter.

7075 T6 Aluminium 5mm chassis plate

The 5mm aluminium chassis has perfect symmetrical shape for even flex and weight distribution.

The wire type front anti-roll bar is ball raced.

It is easy to change and adjust due to the open front end design.

The standard wire is 2.5mm and 2 optional thicknesses are available.

The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The steering blocks are connected to the arms with spring steel 8.5mm pivot balls, which run very smooth and well protected in nylon cups, and are easy to adjust with a 2.5 hex tool.

The long durable front lower wishbones are the open-style arms similar to the 977.

An aluminium shock mount plate is screwed onto the lower wishbone.

This allows the shock attachment point to be placed further outwards improving shock motion.

The front lower arms are mounted to the front brackets with nylon holders.

The kit includes 2 versions: in and out.

This system also enables quick and easy front drive shaft maintenance.

Of course the 988 closed arms are usable as well

The left and right interchangeable upper arms are mounted with 3 position nylon suspension pin inserts.

The 3 position inserts allow camber-change adjustments and are held in place by the anodized aluminium top brackets.

Below the top brackets, spacers can be used to change their angle or height.

Caster is adjusted with clips on the upper pivot pins.

The same clips are also used on the lower pivot pins to change wheelbase.

The black anodized aluminium front axle has Japan made one-way bearings. Spring steel drive cups connect to the long and thin spring-steel drive shafts with CVD system.

The ball raced spring steel wheel axles have aluminium quick-change levers.

The open front end design allows for very fast and easy removal of the front axle and driveline parts.

The central mounted seervosaver allows easy and fast Ackermann adjustment.

The servosaver features a top mounted insert which can be used in 3 positions. Another 2 Ackermann positions are available on the steering blocks.

The rear end construction with aluminium brackets is a very open design, which allows for easy of maintenance and cleaning.

Dis-assembly requires the removal of only a few screws. Replacing a belt if needed, is a simple task.

The eccentric bearing holders on the rear shaft allow adjustment of belt tension.

The whole rear end can be removed as one unit from the chassis by removal of only a few screws.

The wire type rear anti-roll bar is ball raced. It is mounted in the rear bearing blocks and is easy to change and adjust.

The standard wire is 2.5mm and 2 optional thicknesses are available.

The pivot ball link system directs the suspension movement to the bar and allows easy tweak adjustment.

The narrow solid rear axle in Serpent spring steel has a lightweight 9mm wide 48T pulley.

The axle has a double slot for the driveshaft pin for lightness and long life.

Spring steel, CVD type, drive shafts connect the rear shaft to spring steel wheel-axles with aluminium quick-change levers.

A very durable and long lasting drivetrain.

The rear floating body mount which is mounted on the up-rights with 2 arms is centred by a carbon-fibre and steel guider.

The mount has 4 positions on each side to choose from, depending on body shell used and traction available.

The threaded holes on the end of the body mount give the option to add further body-supports.

Optionals

A large selection of optional parts is available to even further improve performance, speed, weight and looks.www.serpent.com/903020

Communications

- Website

- Promo page

- Facebook page

- Viper 990 Facebook user group

- YouTube video’s

- Online set-up sheets

- Support from distributors, dealers and team drivers worldwide

Merchandising

A nice selection of shirts, sweaters, jackets, caps, bags, tools and decals.

Design

Serpent Viper 990 . Designed by Michael Salven.

With great help from all team-drivers and 989/988 drivers!